Handkerchief paper stretching environment-friendly ink and preparation method thereof

An environment-friendly, handkerchief paper technology, which is applied in the field of ink, can solve the problems of high friction coefficient on the surface of ink printed matter, the inability to carry out automatic packaging, and the large impact of ink on the environment, achieving excellent color and luster, excellent shallow plate transfer performance, and good adhesion fastness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

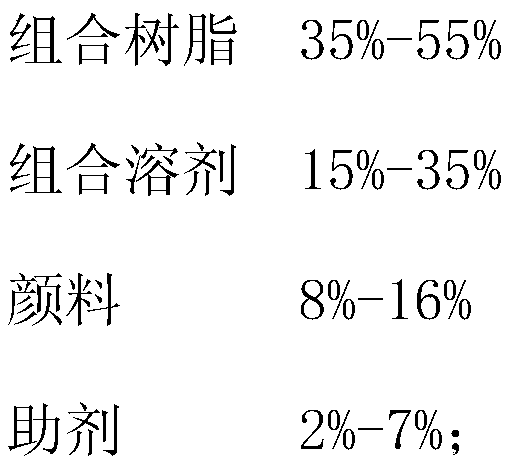

Method used

Image

Examples

Embodiment 1

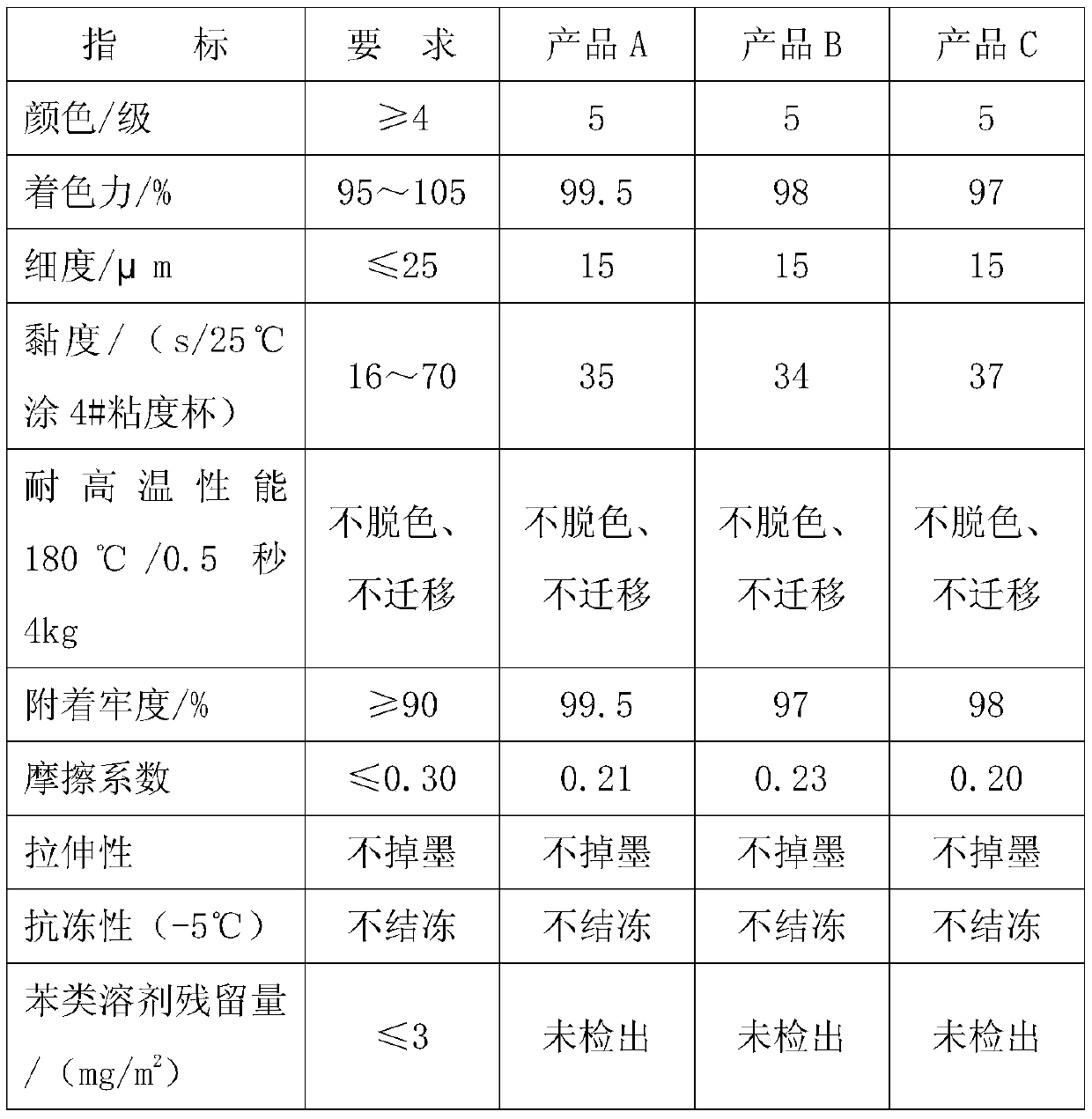

[0020] A handkerchief paper stretching environment-friendly ink, which is composed of the following raw materials in mass percentage: alcohol-soluble polyurethane resin 28%, cellulose nitrate 8%, neutral polyamide resin 10%, PVB resin 4%, modified EVA resin 2%, organic color pigment 12%, polyethylene wax 1%, adhesion promoter 1%, amorphous silica 1%, surfactant 0.6%, n-propyl ester 5%, isopropanol 9.4%, ethyl acetate 9% ester, 5% n-butyl acetate, 4% propylene glycol methyl ether;

[0021] Its preparation method is: mix the above raw materials, except surfactant, adhesion promoter and some solvents, according to the stated ratio, stir and disperse, then grind to obtain a fineness below 20 μm, and then add the stated proportion of surface active agent and adhesion promoter, and add the reserved solvent to adjust the viscosity to reach the 4# cup for 30-40 seconds, then filter and pack to get "Product A".

Embodiment 2

[0023] A handkerchief paper stretching environment-friendly ink, which is composed of the following raw materials in mass percentage: alcohol-soluble polyurethane resin 25%, cellulose nitrate 6%, neutral polyamide resin 15%, PVB resin 3%, modified EVA resin 3%, organic color pigment 10%, polyethylene wax 0.8%, adhesion promoter 1.2%, amorphous silica 1.5%, sulfonate surfactant 0.8%, n-propyl ester 3%, isopropanol 8 %, ethyl acetate 10%, n-butyl acetate 6%, propylene glycol methyl ether 6.7%;

[0024] Its preparation method is: mix the above raw materials, except surfactant, adhesion promoter and some solvents, according to the stated ratio, stir and disperse, then grind to obtain a fineness below 20 μm, and then add the stated proportion of surface active agent and adhesion promoter, and add the reserved solvent to adjust the viscosity to reach the 4# cup for 30-40 seconds, then filter and pack to get "Product B".

Embodiment 3

[0026] A handkerchief paper stretching environment-friendly ink, which is composed of the following raw materials in mass percentage: 30% alcohol-soluble polyurethane resin, 10% cellulose nitrate, 8% neutral polyamide resin, 5% PVB resin, modified EVA resin 2%, organic color pigment 16%, polyethylene wax 1.2%, adhesion promoter 0.9%, amorphous silica 1.2%, surfactant 0.5%, n-propyl ester 6%, isopropanol 7.5%, ethyl acetate 6.7% ester, 2% n-butyl acetate, 3% propylene glycol methyl ether;

[0027] Its preparation method is: mix the above raw materials, except surfactant, adhesion promoter and some solvents, according to the stated ratio, stir and disperse, then grind to obtain a fineness below 20 μm, and then add the stated proportion of surface active agent and adhesion promoter, and add the reserved solvent to adjust the viscosity to reach the 4# cup for 30-40 seconds, then filter and pack to get "Product C".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com