An integrated wire outlet and guide wire mechanism and a steel bar binding machine

An integrated, guide wire technology, which is applied in building construction, building material processing, construction, etc., can solve the problems of installation position deviation, steel wire cannot protrude from the guide, and unstable circle size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

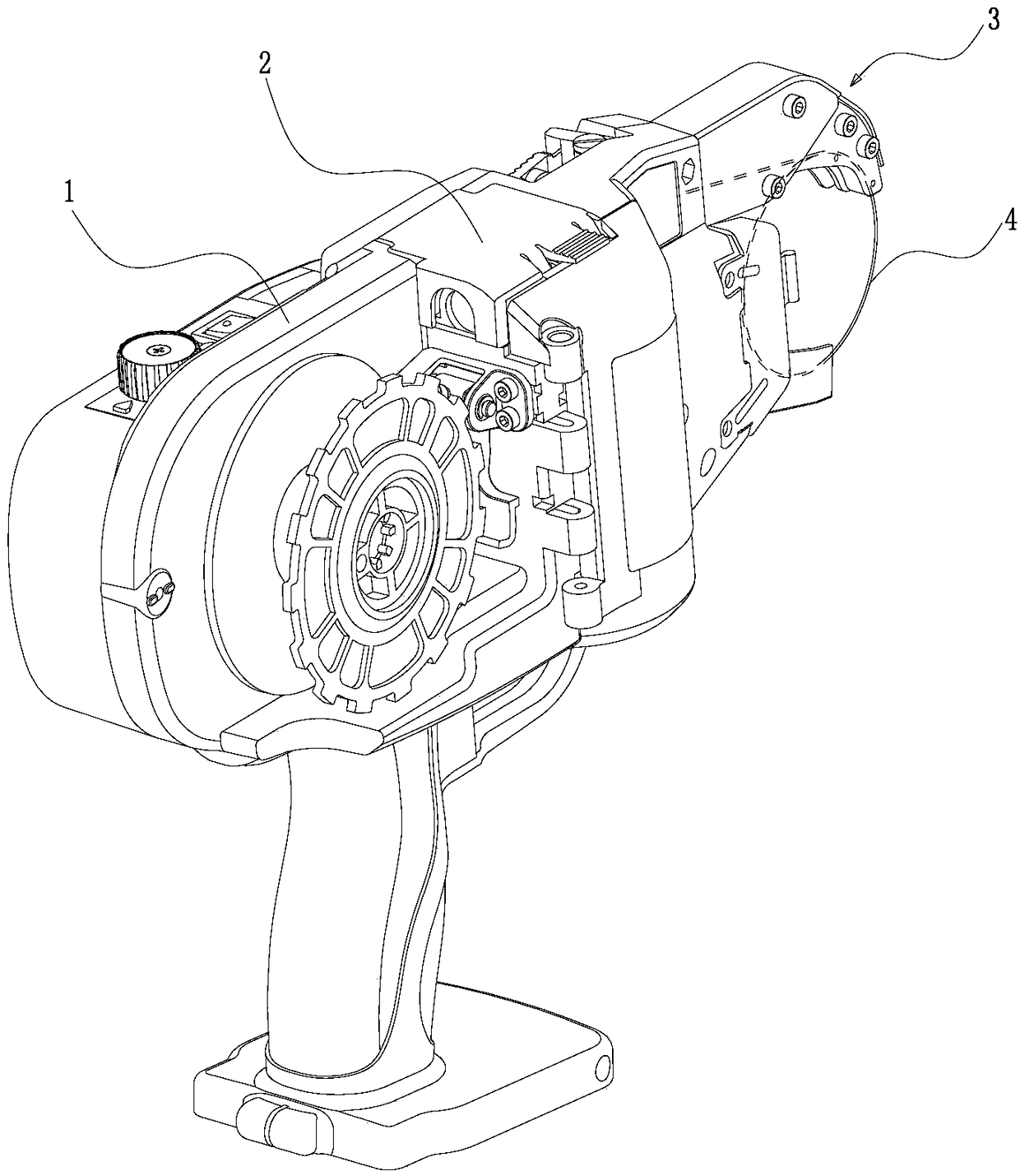

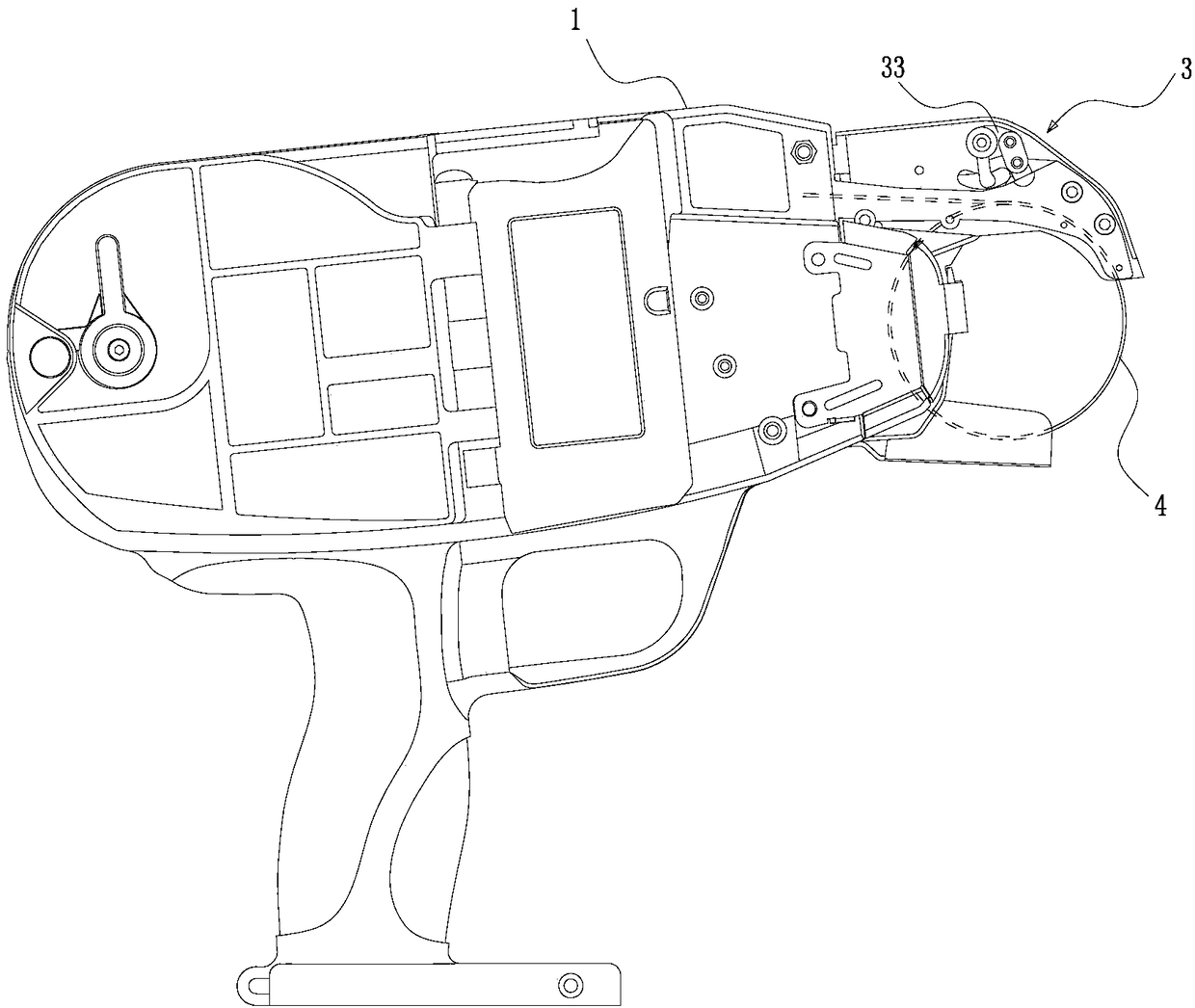

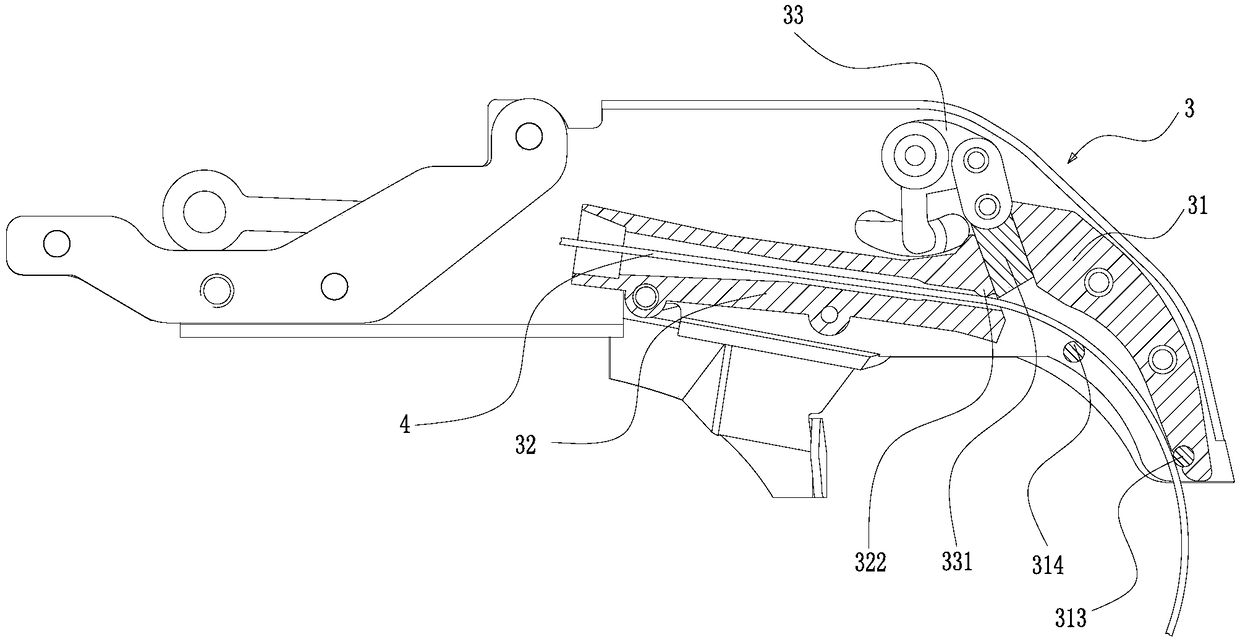

[0033] Such as Figure 1 to Figure 5 As shown, an integrated wire outlet guide mechanism includes a crimped wire outlet part 31 and a wire guide part 32, and the crimped wire outlet part 31 and the wire guide part 32 are laterally formed on a sheet-shaped substrate according to the front and rear positions. A longitudinal groove 34 is provided between the curled wire outlet part 31 and the wire guide part 32, and a boss 311 is provided on the curled wire outlet part 31, and the arc-shaped wall 316 of the boss 311 is lower than the curled wire outlet part 31. A guide portion 312 for guiding the movement of the steel wire is formed on the surface area 317 of the boss 311 , and two guide pieces are arranged in the guide portion 312 . The guide part 312 includes a first steel wire input end A and a first steel wire output end B. A guide member made of a wear-resistant material capable of contacting the steel wire 4 is embedded on the boss 311. The guide member serves as The first...

Embodiment 2

[0040] Figure 6 to Figure 8 As shown, the difference between the structure of the integrated wire outlet guide mechanism and the first embodiment is that a guide is embedded on the upper edge of the second steel wire output end D of the groove 321 as the third guide 323, so The third guiding member 323 is cylindrical. The steel wire 4 passes through the third guide 323 , the second guide 314 and the first guide 313 in sequence, and then bends into a circle.

Embodiment 3

[0042] Such as Figure 9 As shown, the difference between the structure of the integrated wire outlet and guide wire mechanism and that of Embodiment 1 is that the first guide 313 is a straight strip member, and the straight strip member is embedded in the At the first steel wire output end B of the guide part 312, and close to the arc-shaped wall 316 of the boss 311, the steel wire 4 enters the curled wire outlet 31 and moves along the arc-shaped wall 316 of the boss 311. The strip-shaped members contact to complete the crimping of the steel wire 4, and the in-line strip-shaped member can increase the contact area between the steel wire 4 and the guide piece, and the guiding effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com