Hydraulic pump load control system for ground test of aero-engine with two pumps

A load control system and aero-engine technology, which is applied in fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc., can solve problems such as inability to test the vehicle, differences in verification methods, and affect the efficiency of the test run, so as to reduce Quantity, flow stability, and the effect of improving test run efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

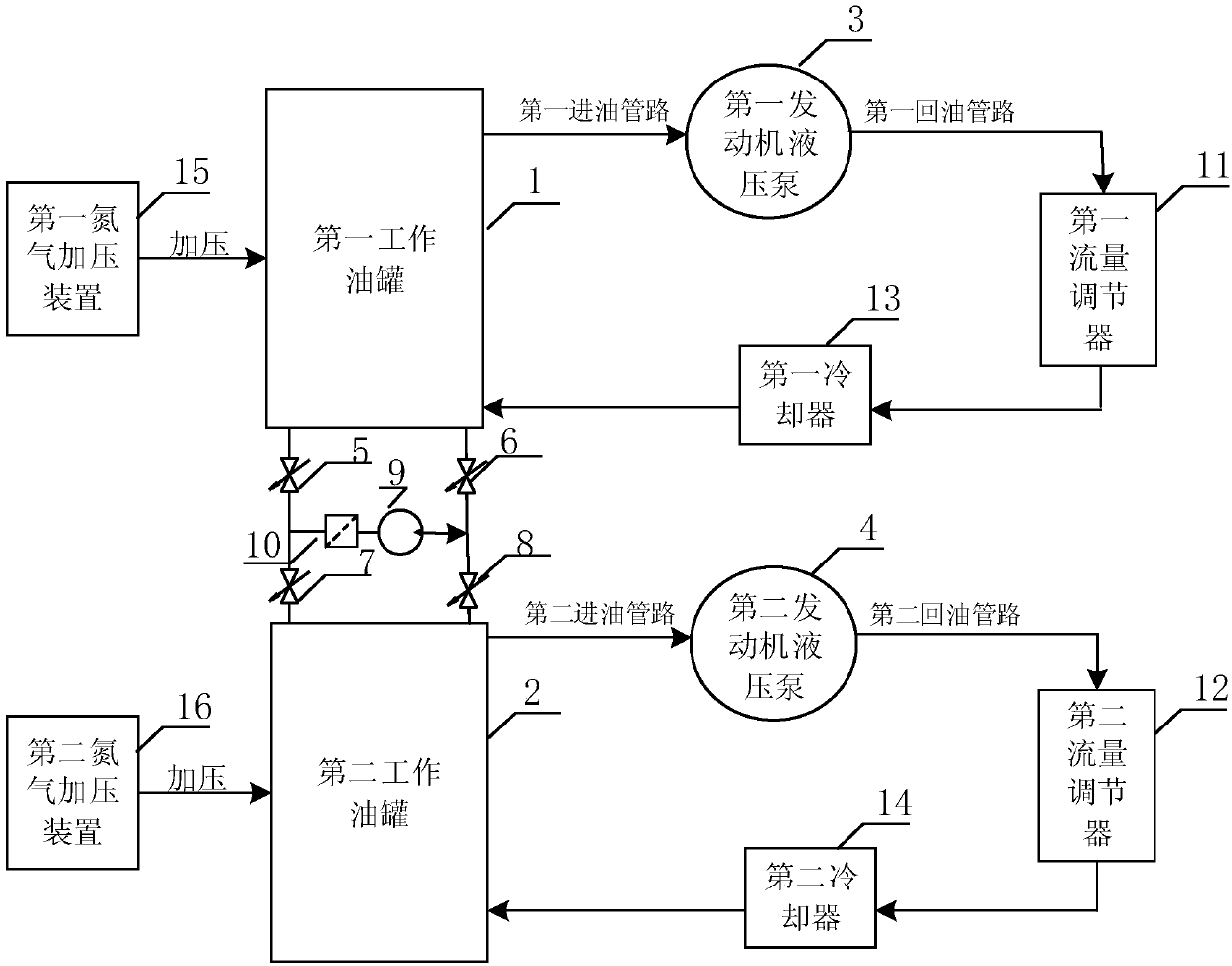

[0022] In this embodiment, the hydraulic pump load control system used for the ground test run of an aero-engine with two pumps is composed of the first hydraulic loading cycle control system, the second hydraulic loading cycle control system and the oil cleaning system, and its structural block diagram is as follows figure 1 As shown, the hydraulic schematic diagram is as follows Figure 4 shown.

[0023] The first hydraulic loading cycle control system includes a first working oil tank 1, a first nitrogen pressurization device 15, a first oil inlet pipeline, a first oil return pipeline, a first flow regulator 11 and a first cooler 13; like Figure 4 As shown, the first working oil tank 1 is provided with a first manual oil discharge valve 20, a first manual air release valve 22 and a first safety valve 23, and the first nitrogen pressurizing device 15 is sequentially composed of the first nitrogen cylinder 15-1, The first remote pressure gauge 15-2, the first pressure redu...

Embodiment 2

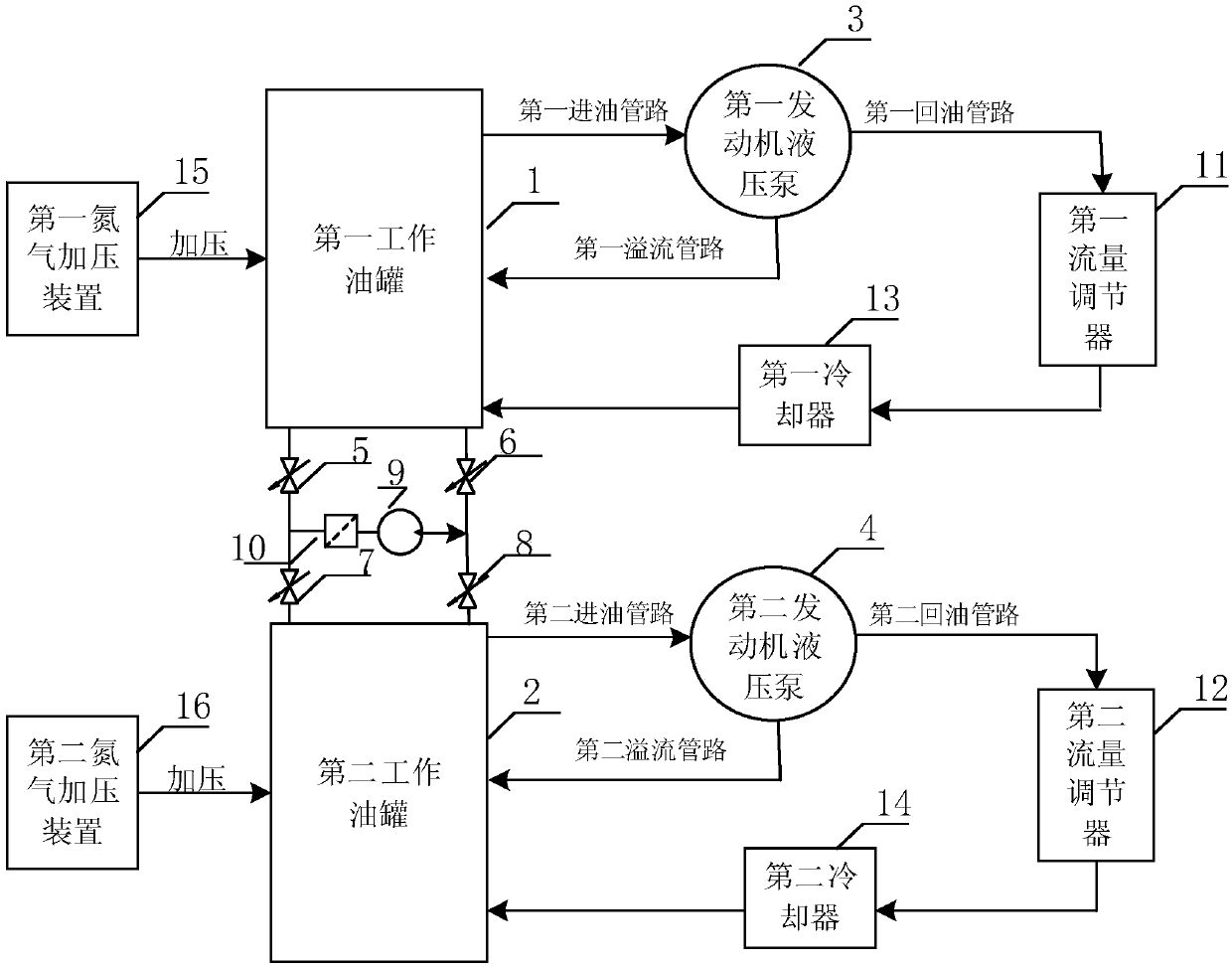

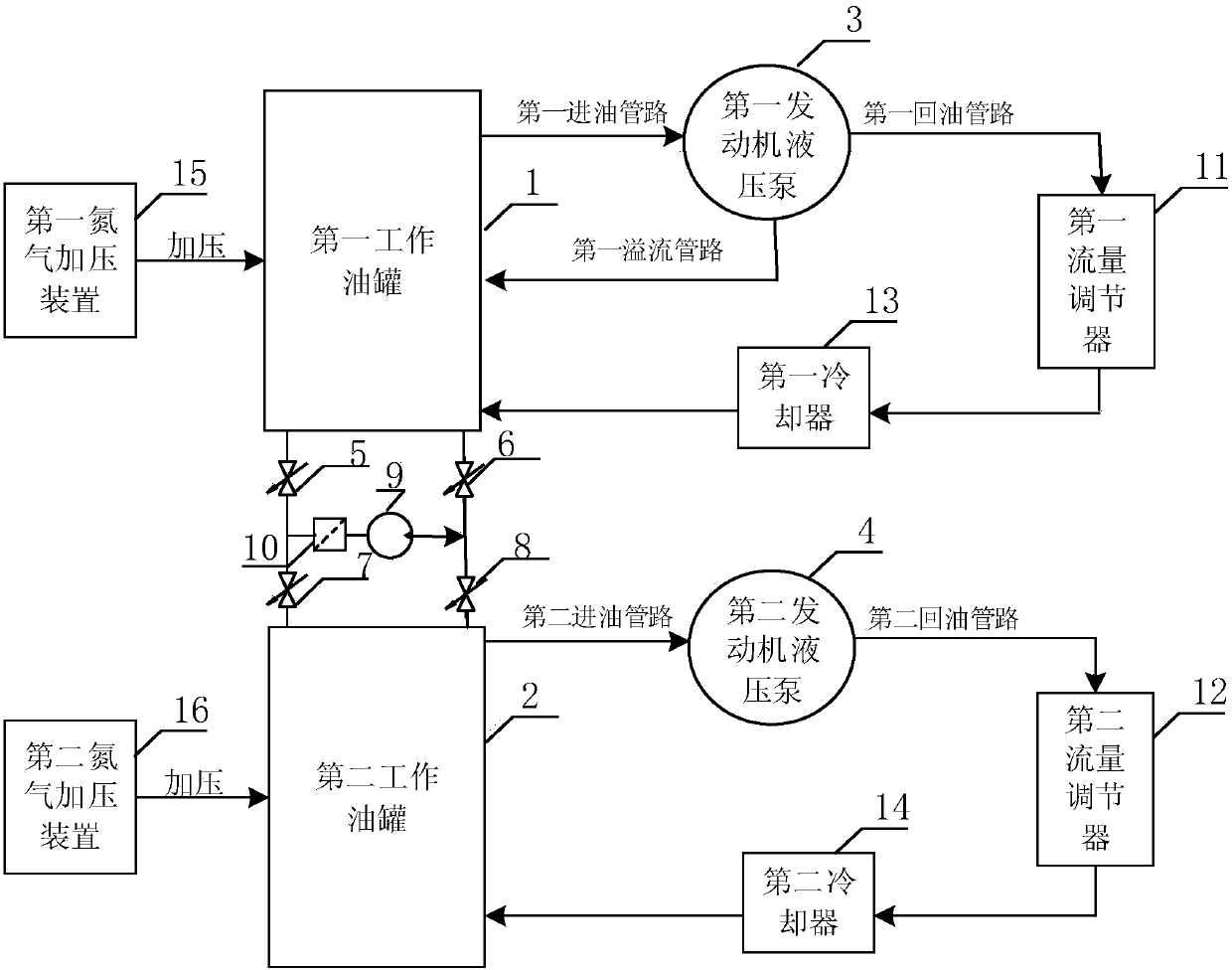

[0031] In this embodiment, the hydraulic pump load control system used for the ground test run of an aero-engine with two pumps is composed of the first hydraulic loading cycle control system, the second hydraulic loading cycle control system and the oil cleaning system, and its structural block diagram is as follows figure 2 As shown, the hydraulic schematic diagram is as follows Figure 5 shown. The difference from Embodiment 1 is: ① Both the first engine hydraulic pump 3 and the second engine hydraulic pump 4 have overflow ports, so the first working oil tank 1 and the second working oil tank 2 are both provided with overflow pipe joints , during the test run, the overflow port of the first engine hydraulic pump 3 is connected to the overflow pipe joint provided by the first working oil tank 1 through the first overflow pipeline, and the overflow port of the second engine hydraulic pump 4 is connected through the second overflow pipe. The overflow pipeline is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com