Camera fixing rack and camera fixing device

A camera fixing frame and camera technology, applied in the direction of machine/stand, supporting machine, mechanical equipment, etc., can solve the problems of lack of local acquisition, inconvenient acquisition of video, lack of clarity of projection range, etc., to ensure consistency and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical means and functions adopted by the present invention to achieve the intended invention purpose, the specific implementation, structure, features and functions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0024] The invention mainly relates to the field of automobile collision safety test, and is mainly used for the safe falling off of various parts at the bottom of the vehicle during the collision process during the collision test, and is mostly used for image collection during the test process of simulating a mule car, and for pulling a car at high speed. The safe detachment of the chain on the horns of the traction trolley and the trajectory of the moving image for a moment of collision damping in motion.

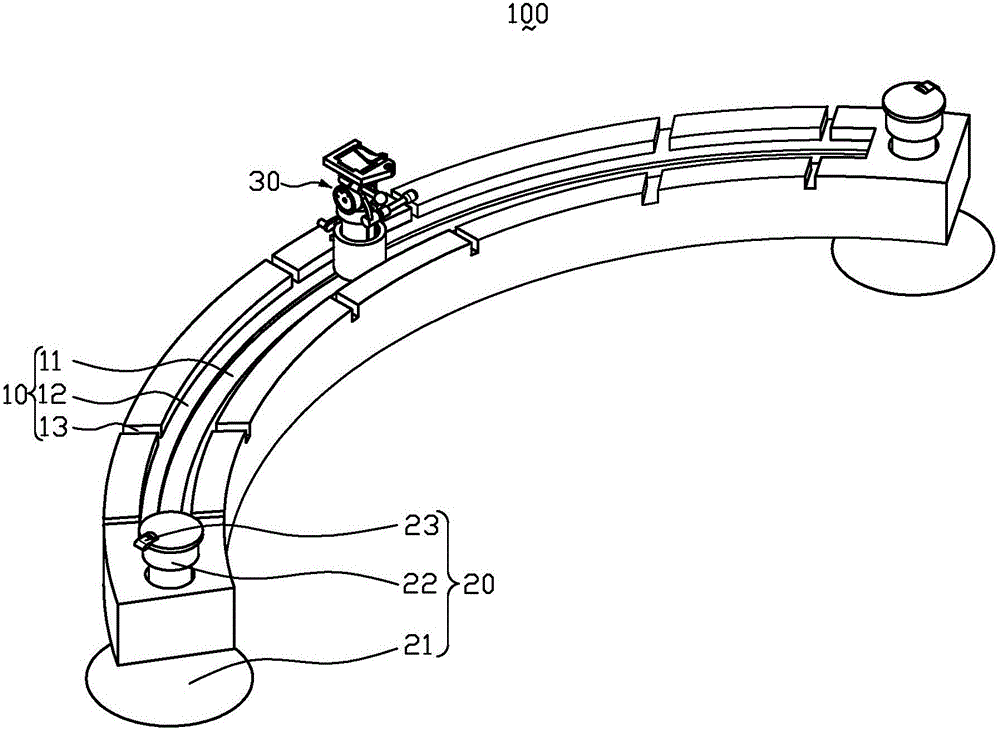

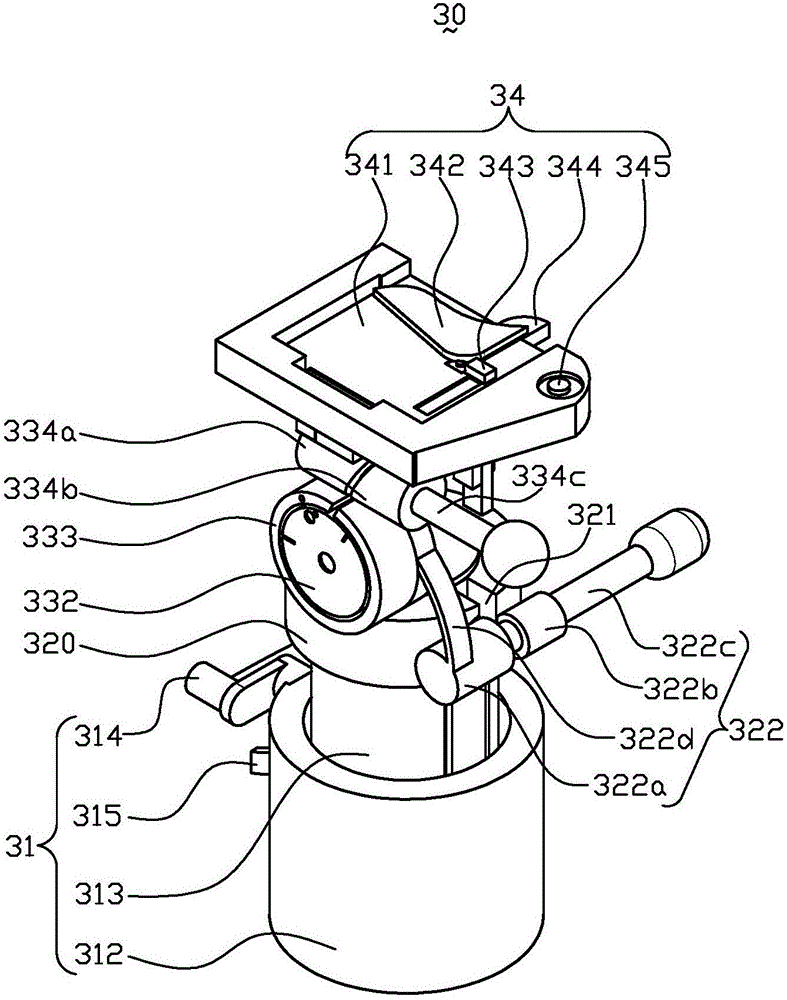

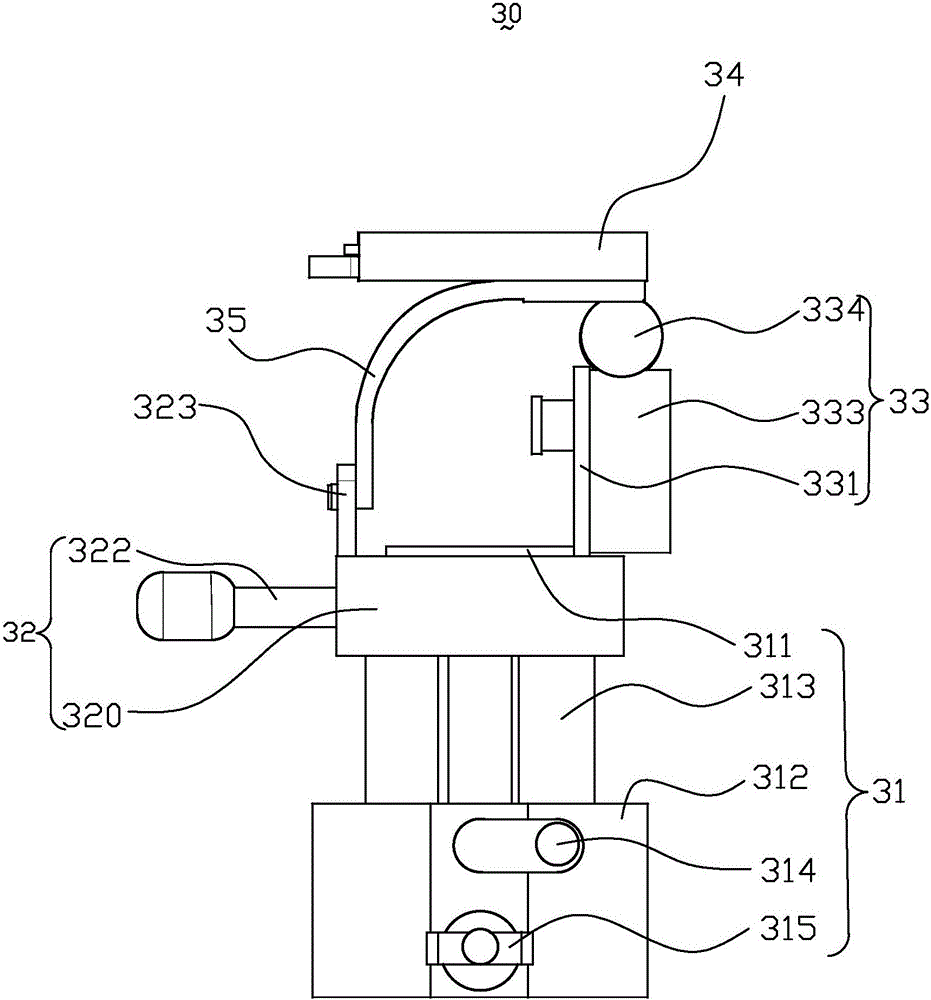

[0025] figure 1 Shown is a schematic structural view of the camera fixing device in the embodiment of the present invention, as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com