Fiber grating type sensor

A fiber grating and sensor technology, applied in instruments, optical devices, measuring devices, etc., can solve the problems of limiting the radial size of the sensor, being easy to corrode, and reducing the spatial resolution of deep displacement monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

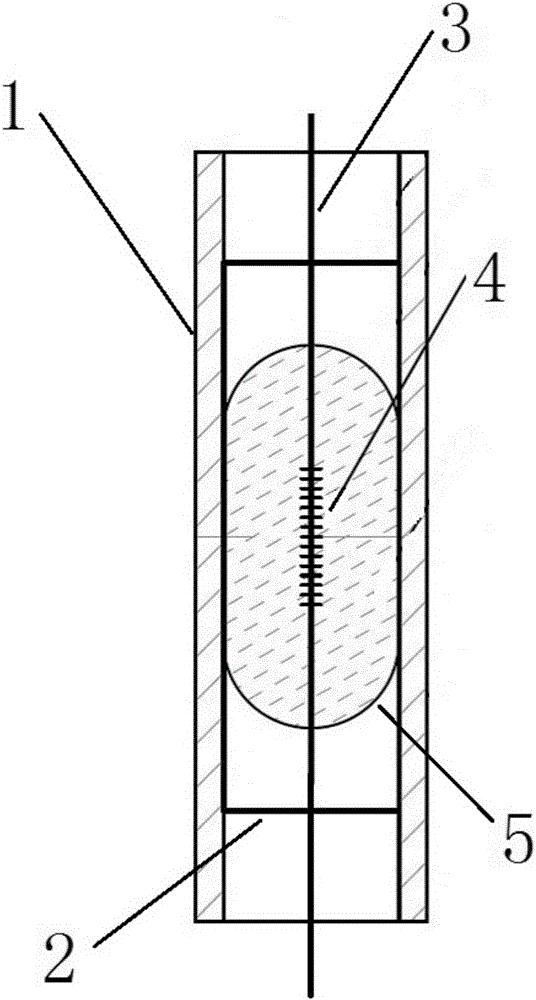

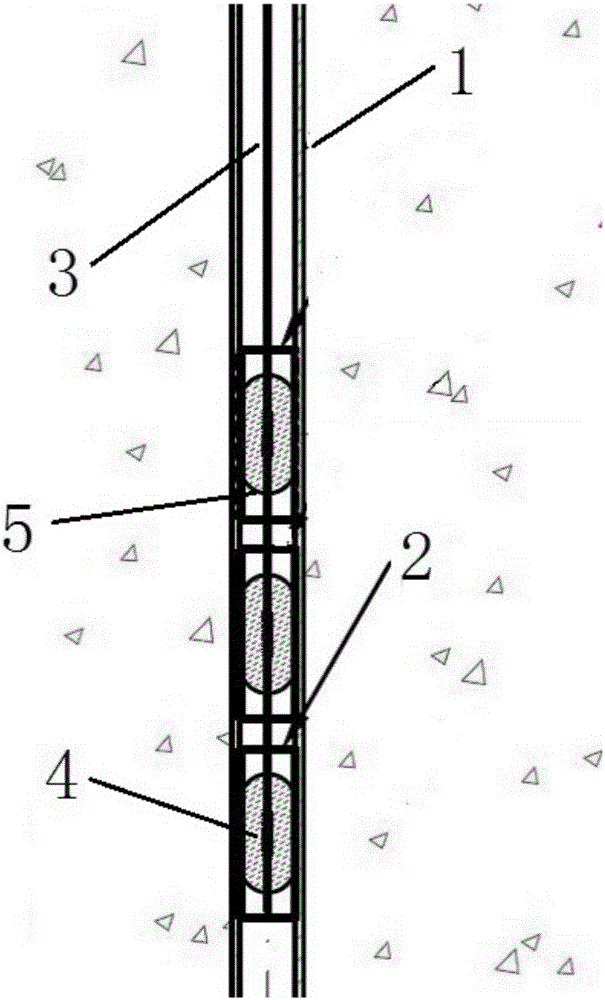

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0024] In the present invention, in the absence of a contrary statement, the used orientation words such as "inner and outer" refer to figure 1 inside and outside of the sensor shown.

[0025] The present invention provides a sensor, which includes an optical fiber 3 provided with a fiber grating 4, a casing 1, and the fiber grating 4 arranged in the casing 1 for transmitting the deformation of the casing 1 to One end of the optical fiber 3 passes through the housing 1 . Set the shell 1 in the slope or roadbed to be monitored. When the slope or roadbed is deformed such as settlement, the shell 1 will be deformed by the force caused by the deformation of the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com