Composite aircraft fuselage section pressurizing test method

A technology of composite materials and aircraft fuselage, applied in the testing of machine/structural components, elastic testing, measuring devices, etc., can solve the problem of lack of experience in applying composite materials to aircraft main load-bearing structures and lack of design and manufacture of composite structures and verification methods, etc., to achieve the effect of simple and efficient method of pressurization test of composite aircraft fuselage section, improvement of technical level and maturity, and high measurement accuracy

Active Publication Date: 2017-04-26

SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

View PDF10 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] More than 90% of the aircraft structures currently in service in China are aluminum alloys, and the amount of composite materials is very small, and they are all used in the secondary load-bearing s

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

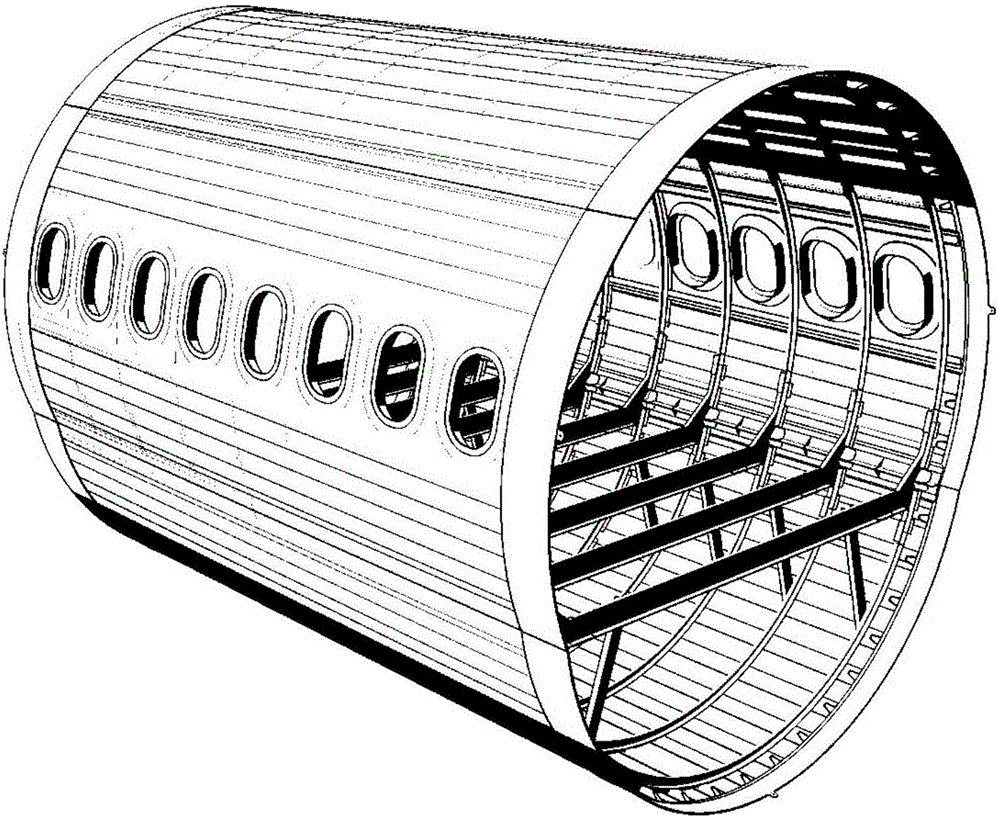

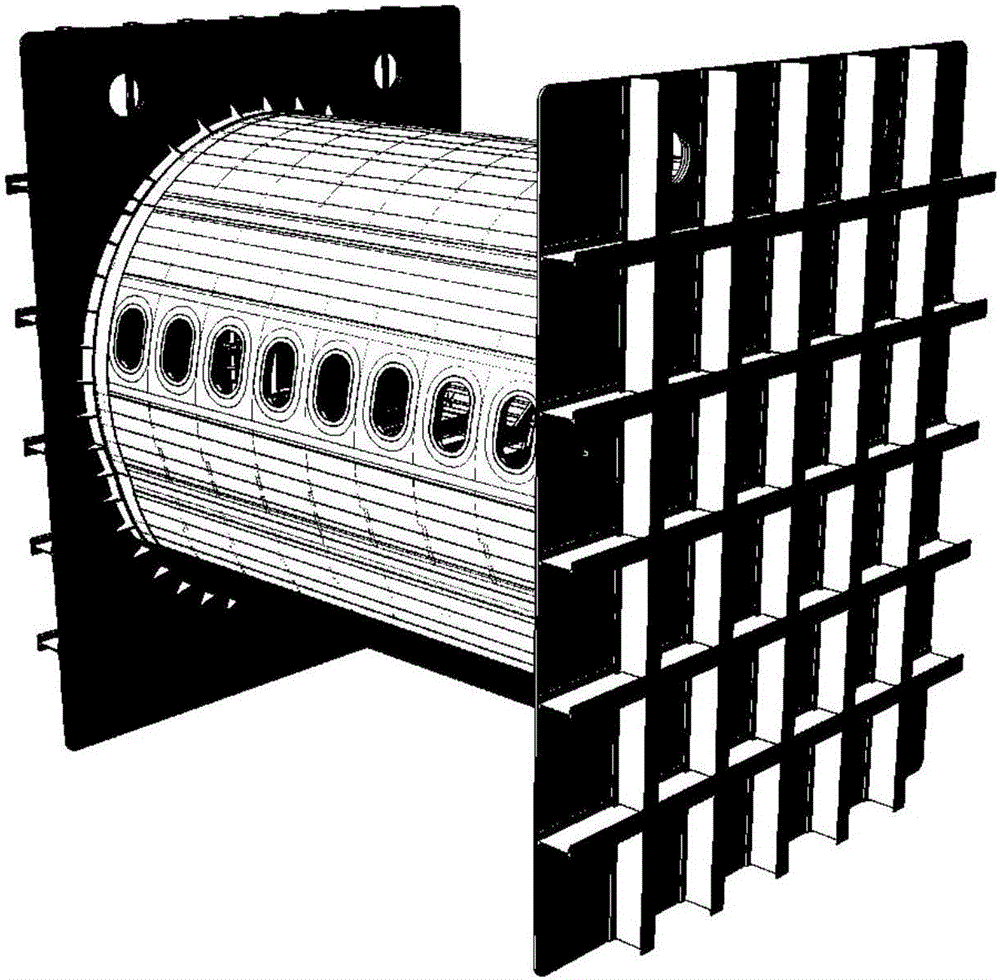

The invention relates to a composite aircraft fuselage section pressurizing test method comprising the following steps: preparing a test piece, wherein the test piece includes a composite aircraft fuselage section and metal test fixtures, the composite aircraft fuselage section further includes a composite skin, a composite frame and a metal connector, and the metal test fixtures are held at the two ends of the composite aircraft fuselage section; arranging a strain acquisition device and a displacement acquisition device on the test piece to acquire the strain and displacement of the composite aircraft fuselage section; and after filling the inside of and sealing the composite aircraft fuselage section, conducting pressure test. The composite aircraft fuselage section pressurizing test method of the invention is accurate in measurement, and can provide reference for fuselage section pressurizing test of domestic large civil aircrafts and new regional aircrafts so as to improve the technological level and maturity of composite materials used in domestic civil aircraft structures.

Description

technical field [0001] The invention belongs to the technical field of aircraft design, and in particular relates to a composite material aircraft fuselage section pressure charging test method. Background technique [0002] As we all know, in aircraft design, composite materials are more and more widely used in aircraft structures due to their excellent properties such as high specific stiffness / specific strength, corrosion resistance, and fatigue resistance. Composite materials can effectively reduce the weight of the aircraft structure and increase the commercial load of the aircraft; or increase the amount of fuel and increase the range of the aircraft. On the other hand, the application of composite materials can reduce the number of aircraft structural inspections, increase inspection intervals, and reduce aircraft maintenance costs, thereby fundamentally improving the economic benefits of civil aircraft throughout their service life. [0003] For foreign advanced civ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M5/00

CPCG01M5/005

Inventor 王瑜胡海阳王振世刘利阳

Owner SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com