Hardware-in-loop test bench suitable for automobile steer-by-wire

A technology for automobile lines and test benches, applied in general control systems, program control, electrical testing/monitoring, etc., can solve problems such as high cost, large space occupation, hidden danger of oil leakage in hydraulic systems, etc., and achieves simple structure and can be adjusted. , The effect of convenient installation and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and embodiment the present invention is further described

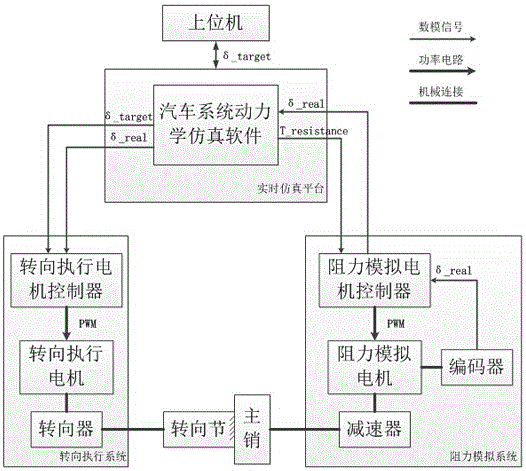

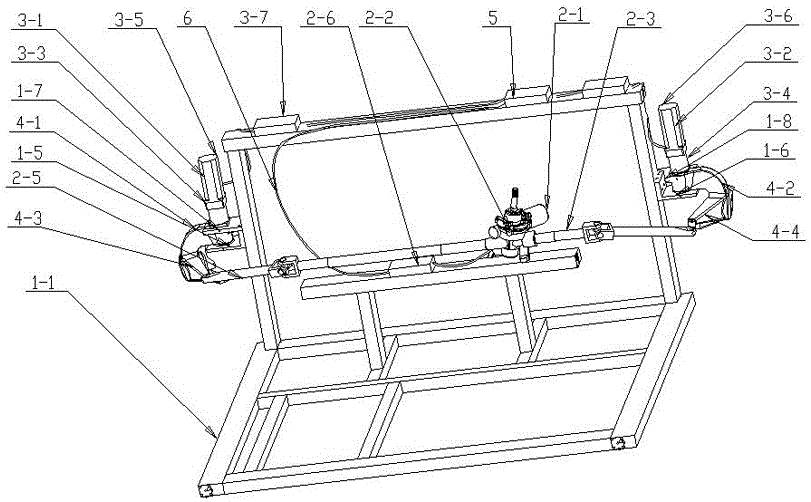

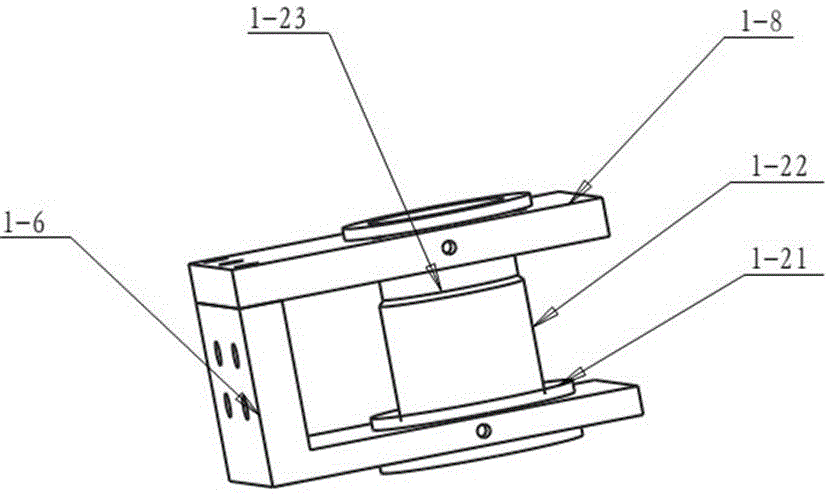

[0038] Such as figure 2 As shown, a hardware-in-the-loop test bench suitable for automobile steering by wire includes a support device 1, a steering execution system 2, a resistance simulation system 3, two steering knuckles 4, a real-time simulation platform 5 and a signal transmission cable 6, according to figure 2 and image 3 As shown, the support device 1 includes: a bottom support frame 1-1, left and right steering knuckle suspension rods 1-2 and 1-12, steering execution system support plate 1-3, left and right steering knuckle support plates 1-5 and 1-6; The bottom support frame includes a base, a steering execution system support plate installation rod 1-15 and 1-16, a seat slide rail guide rod 1-13 and 1-14 and a steering knuckle arm suspension rod stabilizer rod 1-4; The base includes left and right longitudinal beams 1-19 and 1-20, three crossbeams ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com