Method for finely configuring thickness of shielding layer based on grid cutting

A configuration method and grid segmentation technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of high space occupation requirements for radiation shielding volume, achieve convenient and fast calculation process, reduce overall quality, save The effect of material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

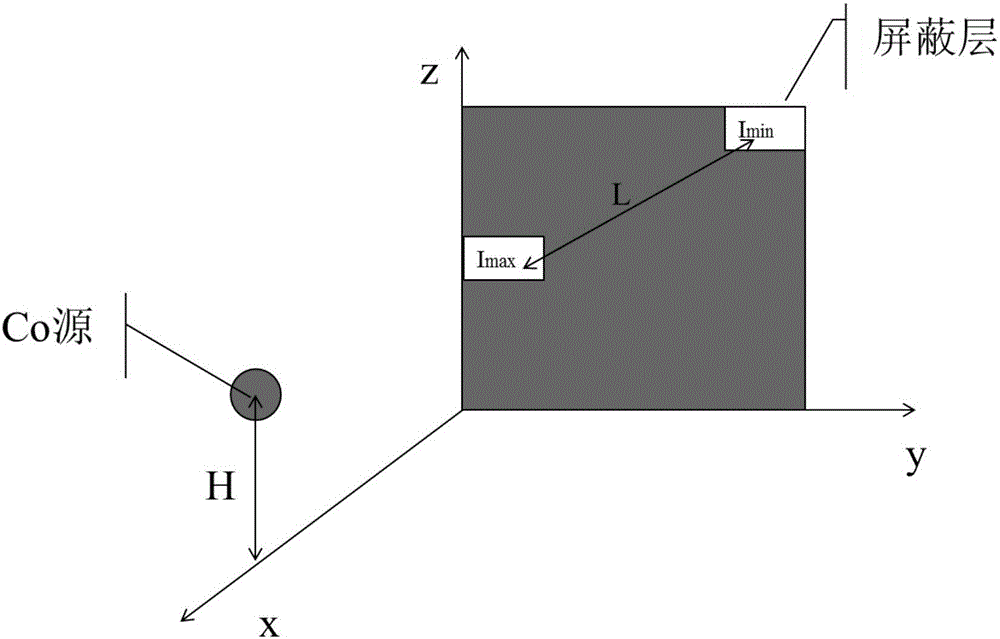

[0035] A Co-60 point source at a location such as figure 2 As shown, the source activity is 4000 Curies, and the allowable dose rate outside the shielding layer is I 0 = 0.25 mR / h. The protective layer of lead material is adopted, and the shielding surface size of the protective layer is 10m×4m.

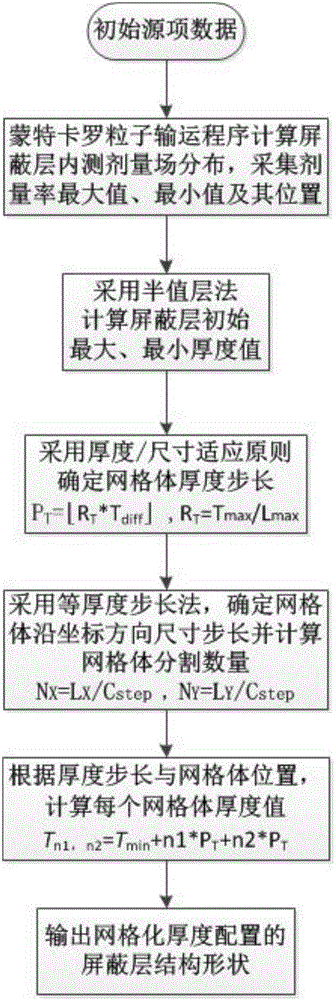

[0036] In this case, the position of the point source is on the far left side, and the radiation dose field inside the shielding layer is extremely unevenly distributed on the plane of the shielding layer. The fine thickness configuration method of the shielding layer based on grid division of the present invention is adopted to carry out the shielding layer plane in this embodiment. Right-angle mesh division, and fine thickness configuration for each mesh body. The steps of this method include five steps.

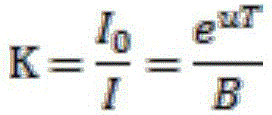

[0037]In the first step, the Monte Car...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap