Reliability-based maintenance evaluation method

A reliability and basic data technology, applied in the direction of instruments, technical management, data processing applications, etc., can solve problems such as high maintenance costs, excessive or insufficient maintenance, maintenance, complex maintenance, etc., to achieve comprehensive evaluation and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

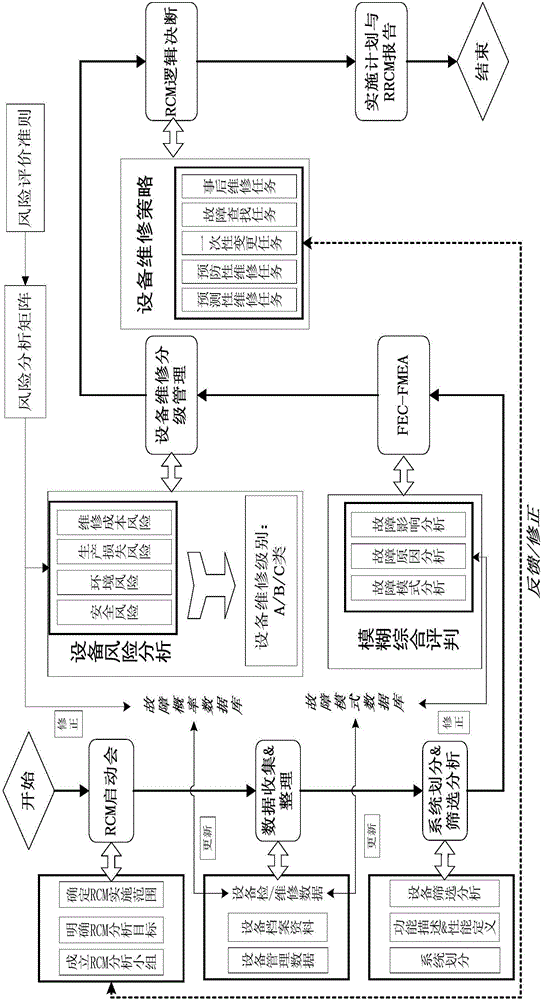

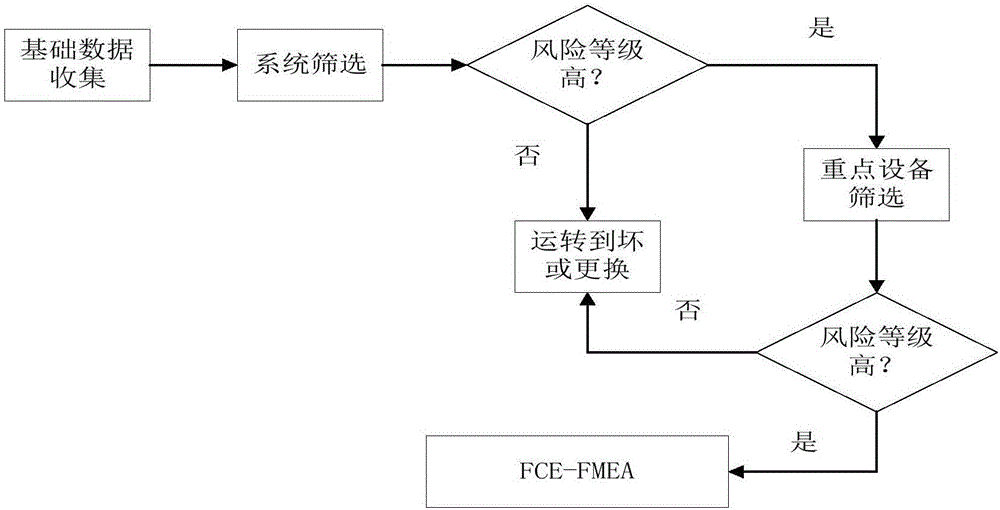

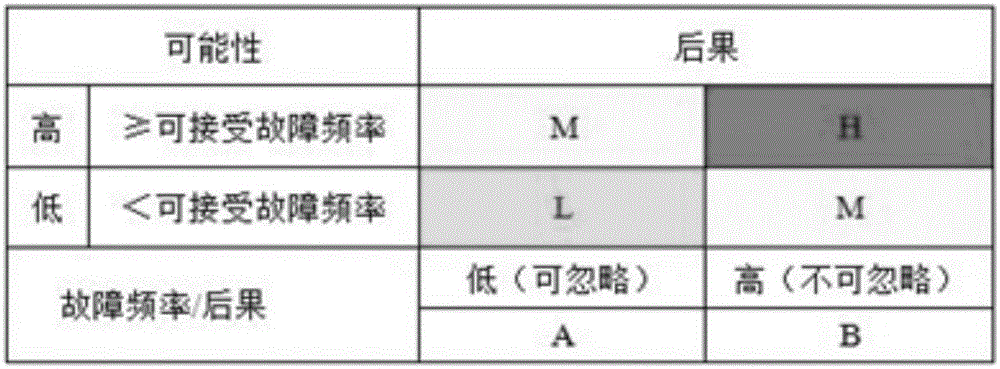

Method used

Image

Examples

Embodiment

[0135] Taking the basic data of a certain equipment of a certain production line as an example, the reliability maintenance evaluation method based on fuzzy comprehensive evaluation of the present invention will be introduced below.

[0136] (1) Determine the implementation scope of reliability maintenance assessment

[0137] After analysis by the reliability maintenance assessment team, it is determined that the object of this assessment is the liquid sulfur product pump of a certain device, and at the same time, the level of failure mode analysis is set as the equipment level.

[0138] (2) Collection and arrangement of basic data

[0139] The content of reliability maintenance evaluation data collection generally includes product overview, operation status, fault information, maintenance information, cost information and the above information of similar products. The data collected this time are shown in Table 3.

[0140] Table 3 basic data information table

[0141]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com