A Fabrication Method of Stretchable Electronic Devices with Regular Wrinkle Structure

An electronic device and wrinkle technology, which is applied in the field of preparation of stretchable electronic devices with regular wrinkled structure, can solve the problems of being unsuitable for large-scale production, unsuitable for commercial application, and expensive, and achieve fast preparation speed and good shape. The effect of small variance and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

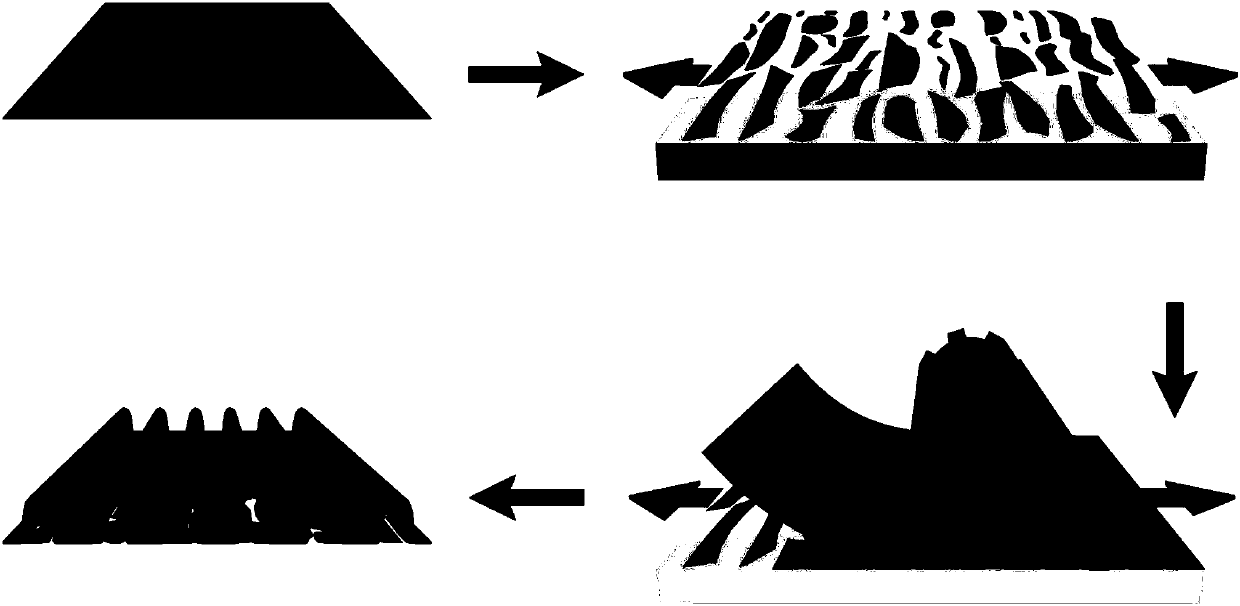

Method used

Image

Examples

Embodiment 1

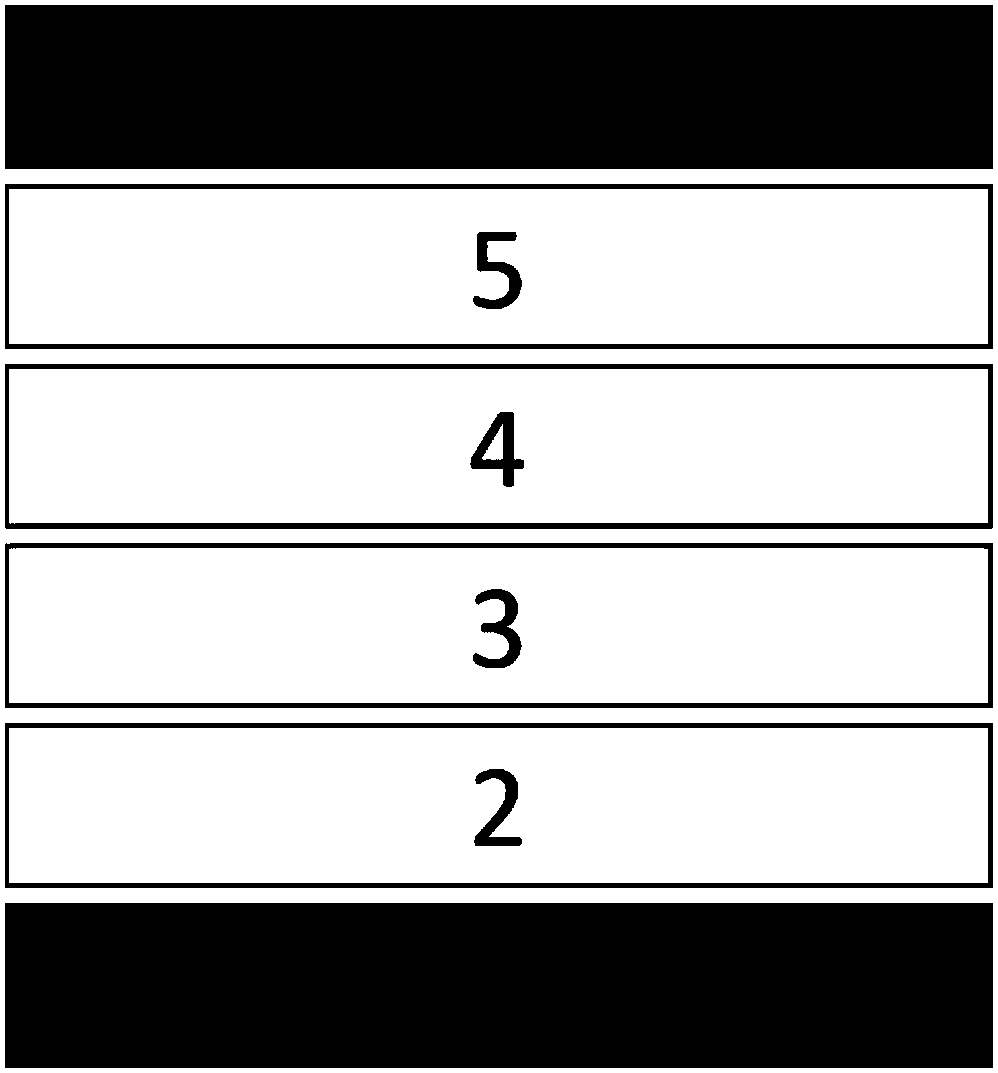

[0039] A stretchable electronic device with regular wrinkled structure, the device structure is: NOA63 / Ag(80nm) / MoO3(3nm) / NPB(40nm) / mCP:Ir(ppy)3(20nm,6%) / TPBi( 35nm) / C a(3nm) / Ag(15nm), such as figure 2 The device structure in .

[0040] A method for preparing a stretchable electronic device with a regular wrinkled structure, the specific steps are as follows:

[0041] (1), preparing a roller with a strip-shaped microstructure on the surface;

[0042] Prepare a roller with a strip-shaped microstructure on the surface, the material used for preparing the roller is polytetrafluoroethylene, the diameter of the roller is 6mm, the length of the roller is 3cm; the width of the strip-shaped microstructure is 450um, and the spacing of the strip-shaped microstructure is 350um , the depth of the strip microstructure is 500um.

[0043] (2), adopt the vacuum evaporation method to prepare the elastic thin film that the surface has metal spacer layer;

[0044] First cut the VHB 4905 ela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com