A module top heating system and control method suitable for soft pack power batteries

A power battery and heating system technology, applied to battery pack parts, secondary batteries, circuits, etc., can solve the problems of unreasonable heat transfer path, high space structure requirements, low heating efficiency, etc. Reasonable heat path and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples serve to illustrate the invention.

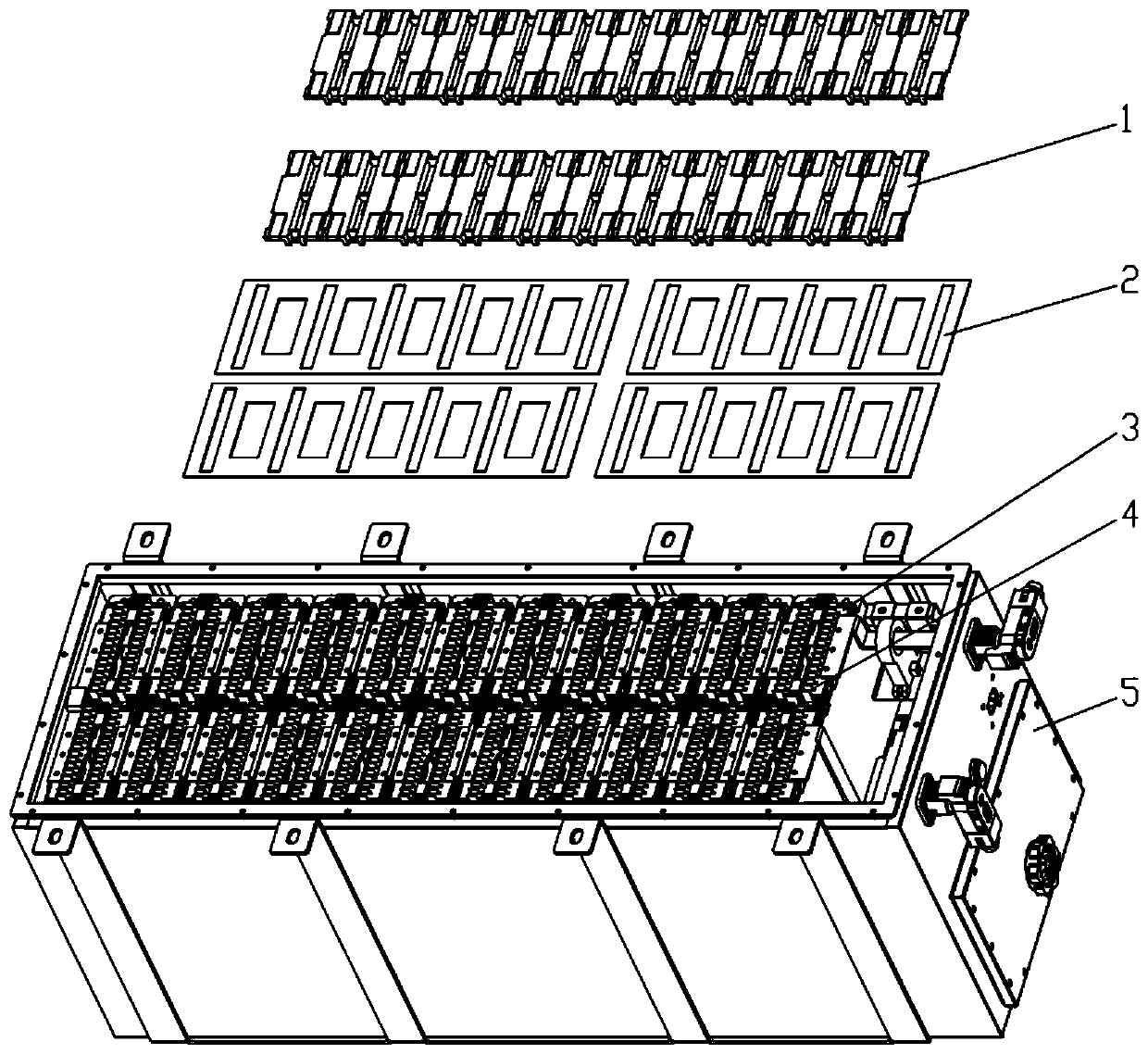

[0028] Such as figure 1 As shown, the schematic diagram of the module top heating system of a soft-pack power battery pack mainly includes a chassis 5, a soft-pack cell module 3, a heater 2, a temperature collector 4, and a BMS (battery management system). According to the shape characteristics of the battery-packing module and the installation position in the battery pack, the heater 2 is made into a corresponding shape, the surface of the heater 2 is insulated, and the heater 2 is pasted on the bus bar of the module 3. Tighten the cover plate 1 of the module to make it press against the heating film 2, set the probe of the temperature collector 4 on the bus bar of the module 3, and connect the heating film 2 and the temperature collector 4 to the BMS.

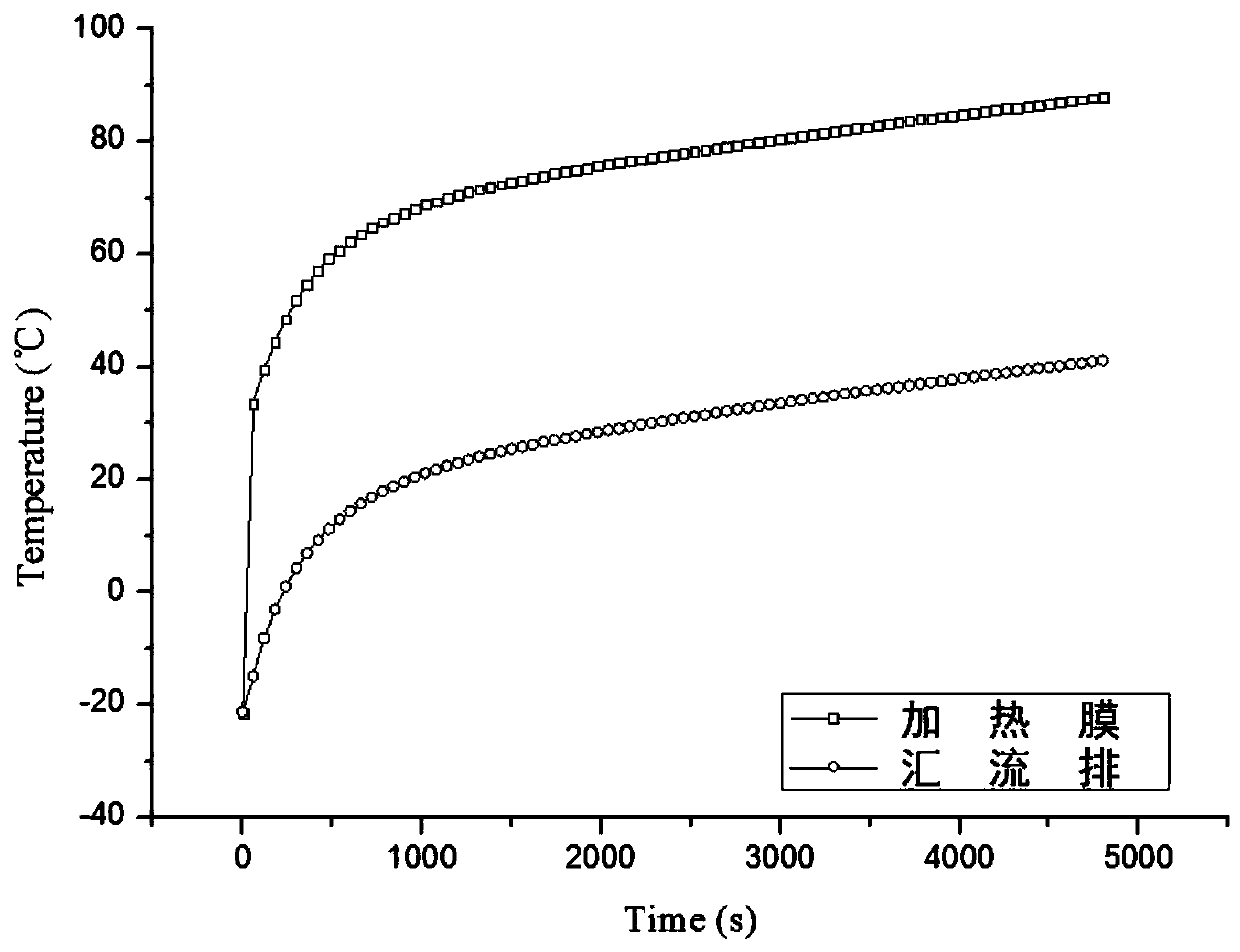

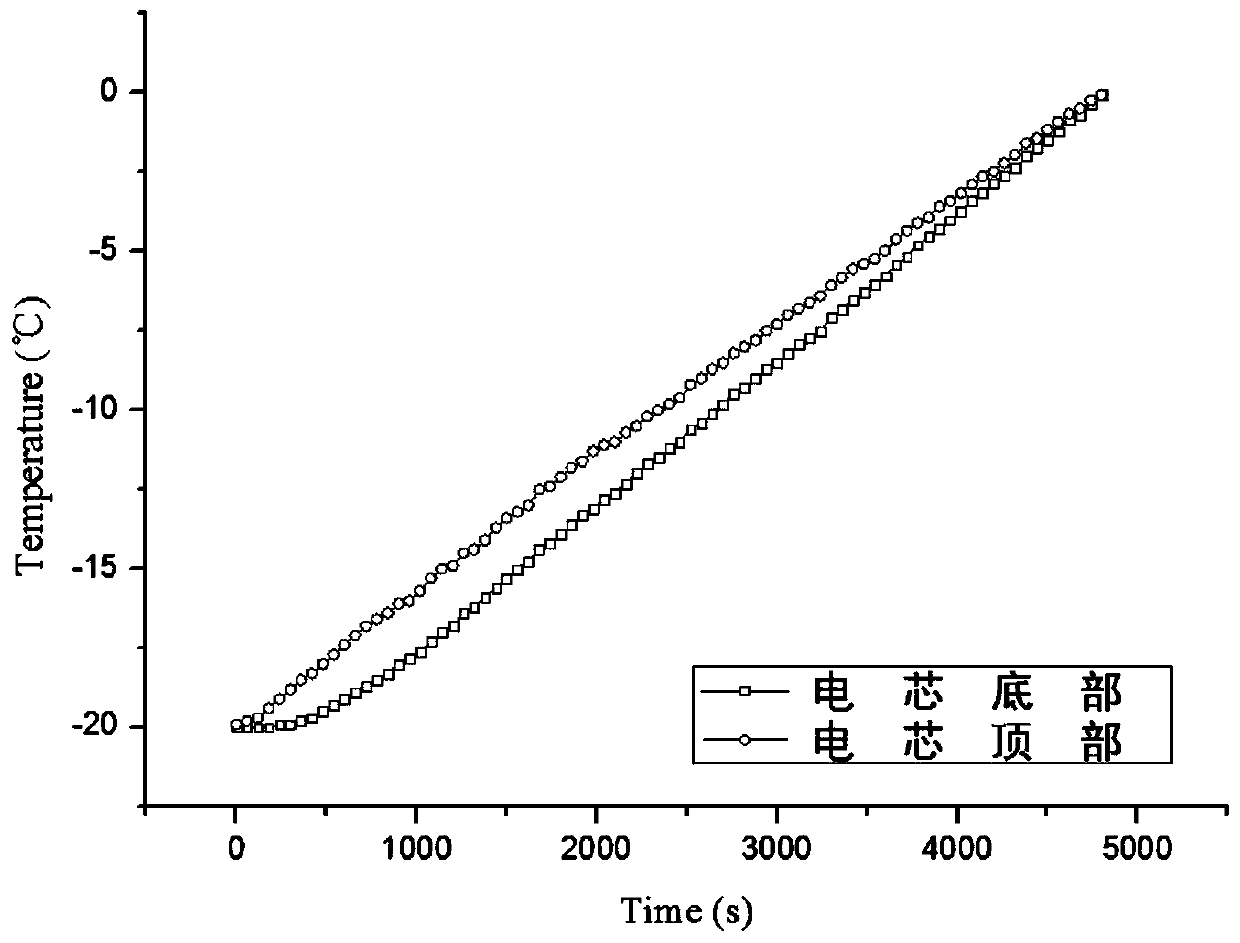

[0029] The heater used in this example is a PI heating film, and the heating power of the heaters corresponding to the positive bus bar area and the negative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com