A substrate-integrated waveguide pyramid horn antenna and its design method

A technology that integrates waveguides and horn antennas on substrates. It is applied in the directions of waveguide horns, antennas, and electrical components. It can solve the problem of increasing demand for low return loss and achieve the effect of low return loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

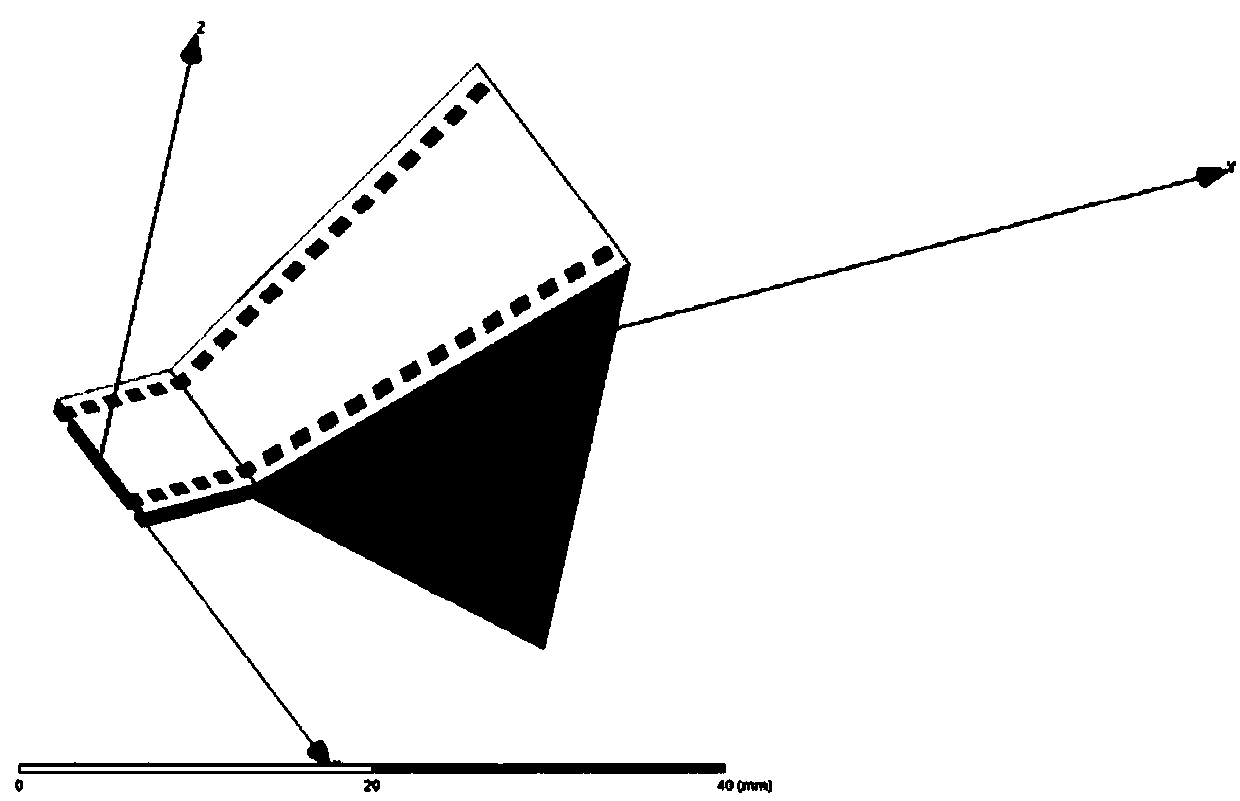

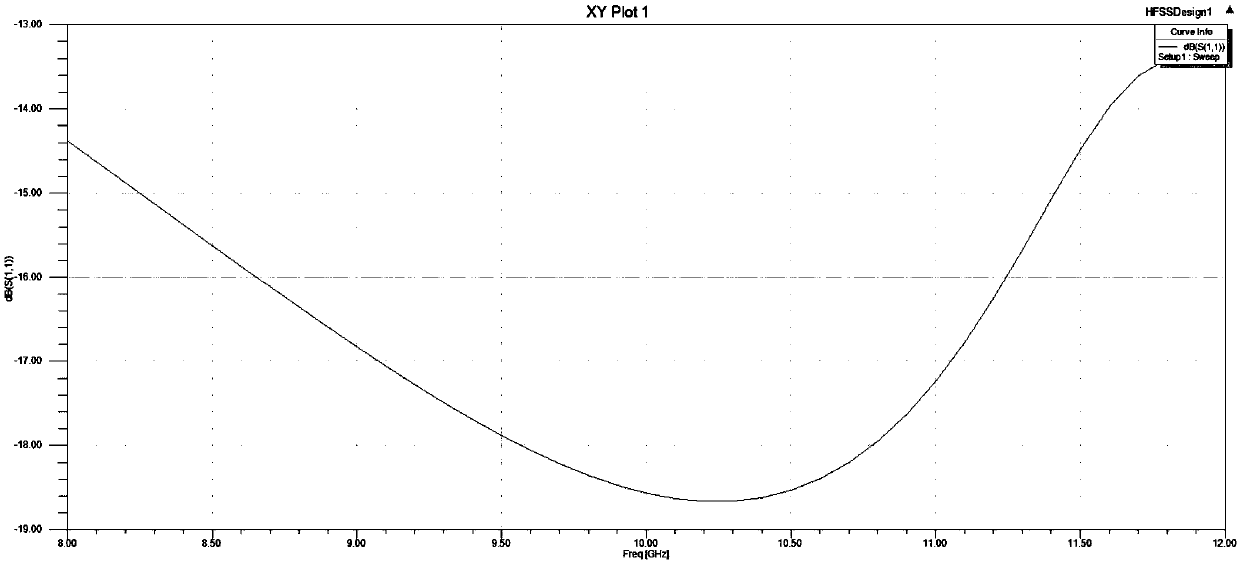

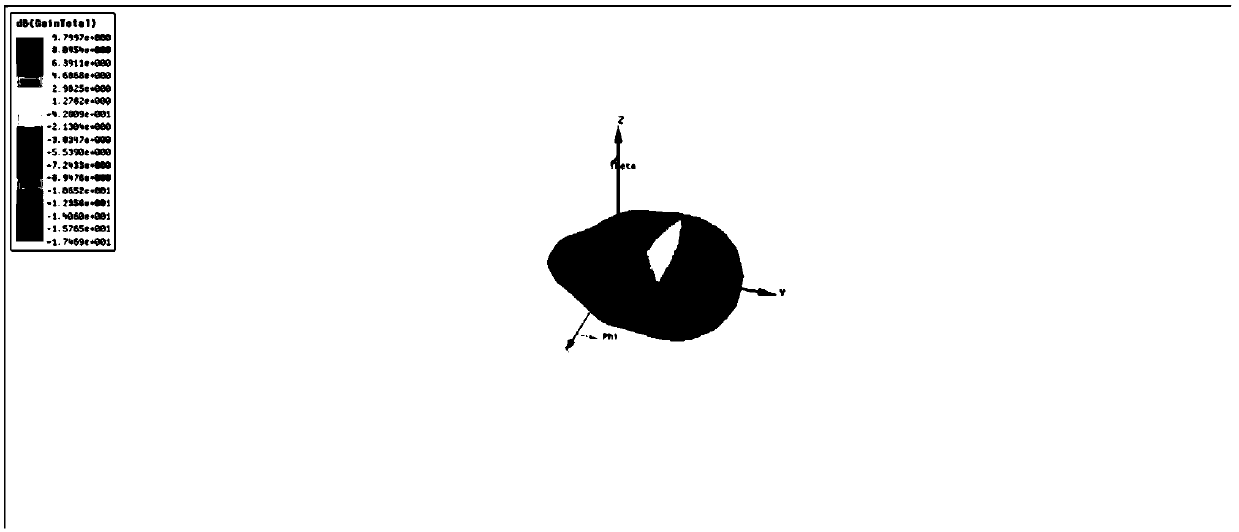

[0021] SIW pyramidal horn antenna, the specific parameters are w1=10.24mm, l1=7.5mm, d=0.8mm, p=1.5mm, w2=18mm, h2=30mm, l2=20mm, w1 is the width of SIW transmission line, L1 is SIW transmission line length, d is the radius of the through hole, p is the pitch of the through hole, the thickness of the substrate is 1mm, the thickness of the copper layer is 0.0175mm, w2 is the wide side of the pyramid horn, h2 is the narrow side of the pyramid horn, L2 is the pyramid horn length. Modeling and simulation in HFSS shows that the return loss is greater than 13dB within 8.5GHz-12GHz.

[0022] Model in HFSS, establish a relative coordinate system on the SIW pyramidal horn antenna, use the quadratic function y=12.5*x*x, 20≤x≤30mm to make a curve, and then translate along the x and y axes, take D1=5mm , D2=1mm, and then make the curve symmetrically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com