Multi-rod closed chain structure mechanical arm for gas cutting blanking operation

A technology for manipulators and operations, applied in the direction of manipulators, claw arms, gas flame welding equipment, etc., can solve the problems of large moment of inertia of manipulators, decreased dynamic performance, and small load-bearing capacity, and achieve high rigidity, no cumulative error, and high load-bearing capacity big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

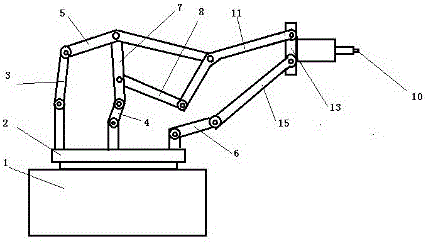

[0006] A multi-rod closed-chain structure mechanical arm for gas cutting blanking operation, comprising: a base 1, a rotatable platform 2, a telescopic mechanism, a lifting mechanism, a pitch mechanism, a wrist 13, a cutting torch 10 and a driving device; the telescopic mechanism includes a first Active lever 3 and boom 5; one end of the first active lever 3 is hinged to the rotatable platform 2, the boom 5 is curved, and one end of the boom 5 is hinged to the other end of the first active lever 3; the lifting mechanism includes: The second active rod 4, the second connecting rod 7, the third connecting rod 8 and the elevating rod 11; The other end is hinged, and one end of the third connecting rod 8 is hinged at the middle part of the second connecting rod 7, and the elevating rod 11 is curved, and one end of the elevating rod 11 is hinged with the other end of the third connecting rod 8; the second connecting rod 7 The other end of the boom 5 is hinged to the middle part of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap