Two-motion-range closed-chain connecting rod mechanism mechanical arm for assembling work

A technology of linkage mechanism and mobility, applied in manipulators, program-controlled manipulators, claw arms, etc., can solve the problems of large arm rotational inertia, decreased dynamic performance, and high precision requirements, and achieve compact structure, no accumulated error, and overcome precision. demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

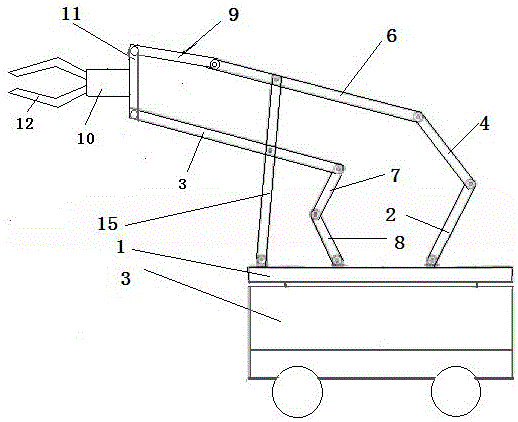

[0006] The present invention provides a kind of mechanical arm of closed-chain linkage mechanism with two degrees of activity for assembly operation, comprising: base 3, rotary platform 1, telescoping mechanism, lifting mechanism, wrist 10 and hand claw 12, driving device, it is characterized in that The telescopic mechanism includes: the first active rod 2, the fourth connecting rod 15, the fifth connecting rod 4, the first connecting rod 6 and the pitch rod 9; one end of the first active rod 2 and the fourth connecting rod 15 is connected to the rotary platform through a hinge 1 connection, one end of the fifth connecting rod 4 is hinged to the other end of the first active rod 2, one end of the first connecting rod 6 is hinged to the other end of the fifth connecting rod 4, one end of the pitch rod 9 is connected to the first connecting rod 6 The other end of the fourth connecting rod 15 is hinged with the middle part of the first connecting rod 6. The lifting mechanism incl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap