Three-degree-of-freedom closed-chain type arc welding machine mechanism

A closed chain, arc welding machine technology, applied in the direction of welding rod characteristics, electrode support devices, etc., can solve the problems of the decline in the dynamic performance of the manipulator, the large cumulative error of the manipulator, and the increase in the load of the drive motor, etc., to achieve compact structure, no cumulative error, The effect of improving dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

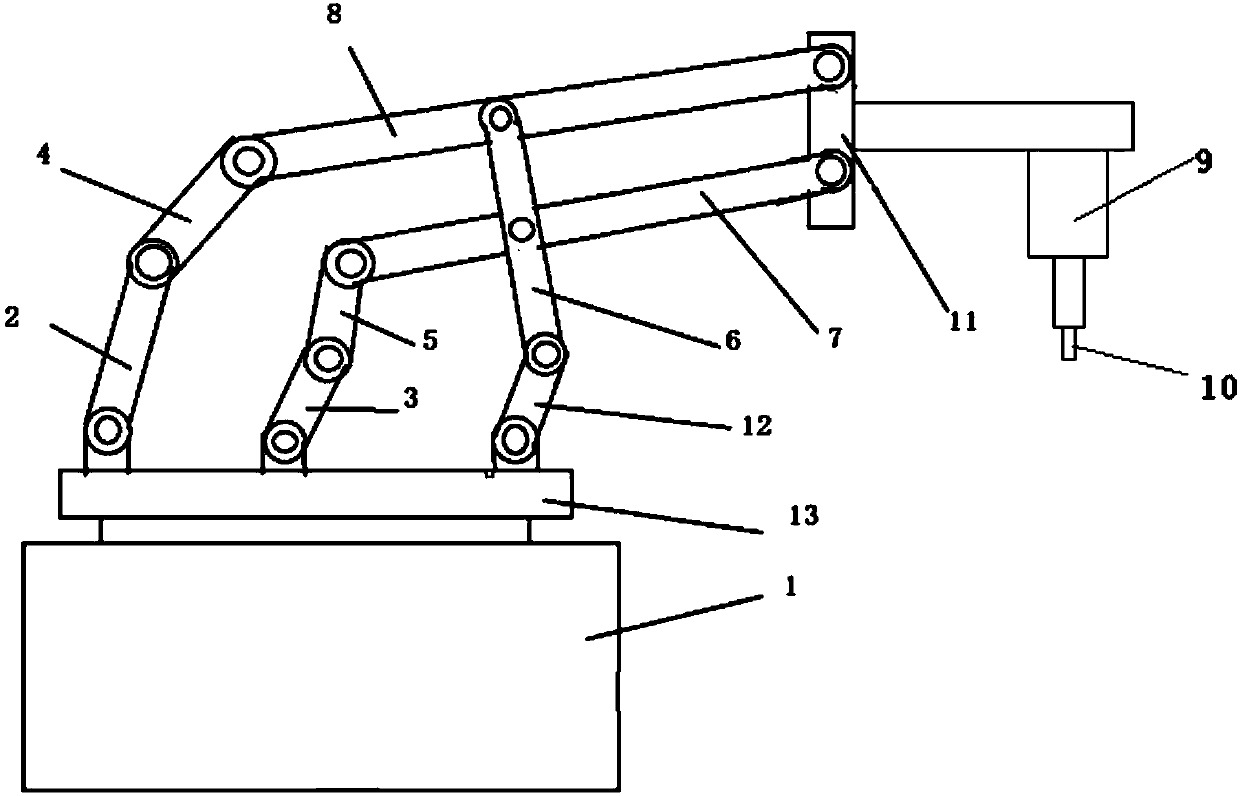

[0006] A three-degree-of-freedom arc welding machine mechanism in the form of a closed chain, including: a base 1, a rotatable platform 13, a telescopic mechanism, a lifting mechanism, a pitching mechanism, and a rotatable wrist link 11. The telescoping mechanism includes: the first active rod 2, the second connecting rod 4 and the first big arm 8; The other end of the first boom 8 is hinged with the other end of the second connecting rod 4 . The lifting mechanism includes a second active rod 3, a third connecting rod 5 and a second big arm 13; one end of the second active rod 3 is hinged on the rotatable platform 13, and one end of the third connecting rod 5 is connected to The other end is hinged, and one end of the second big arm 13 is hinged with the other end of the third connecting rod 5; the pitch mechanism includes: the third active rod 12 and the pitch rod 6; one end of the third active rod 12 is hinged on the rotatable platform 13 , one end of the pitch rod 6 is hin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap