Hand-held automatic wire correction device

A hand-held, automatic technology, applied in the direction of measuring devices, instruments, measuring electronics, etc., can solve problems such as low efficiency and slow measurement speed, and achieve the effects of easy operation, small equipment structure, and improved detection efficiency

Inactive Publication Date: 2017-05-03

PIOTECH CO LTD

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The technical problem to be solved by the present invention is to provide a hand-held automatic calibration equipment, which solves the problem of low efficiency and slow measurement speed in the detection process after the equipment manufacturer purchases the cable; at the same time, it reduces the number of detection personnel and saves detection A lot of time and energy of personnel; improve the efficiency of equipment troubleshooting

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

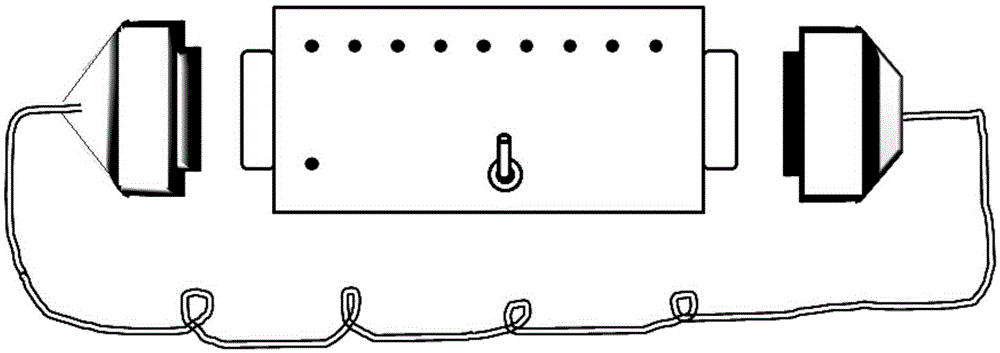

[0029] see image 3 , taking the D-Sub 9Pin Cable as an example, connect the two ends of the cable to the two ends of the handheld calibration device, turn the switch to ON, and the indicator lights of each Pin are normally lit, indicating that the connection of each Pin of the Cable is normal. Not lit, check the cable drawings for comparison and make a final judgment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

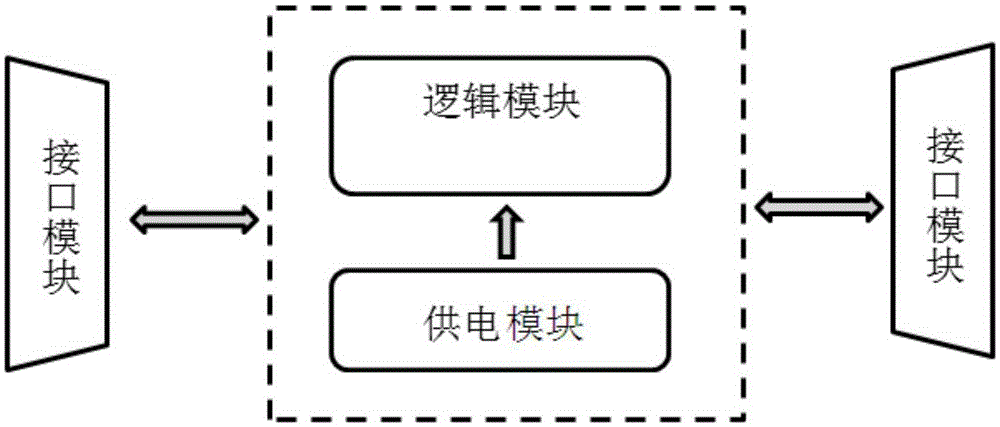

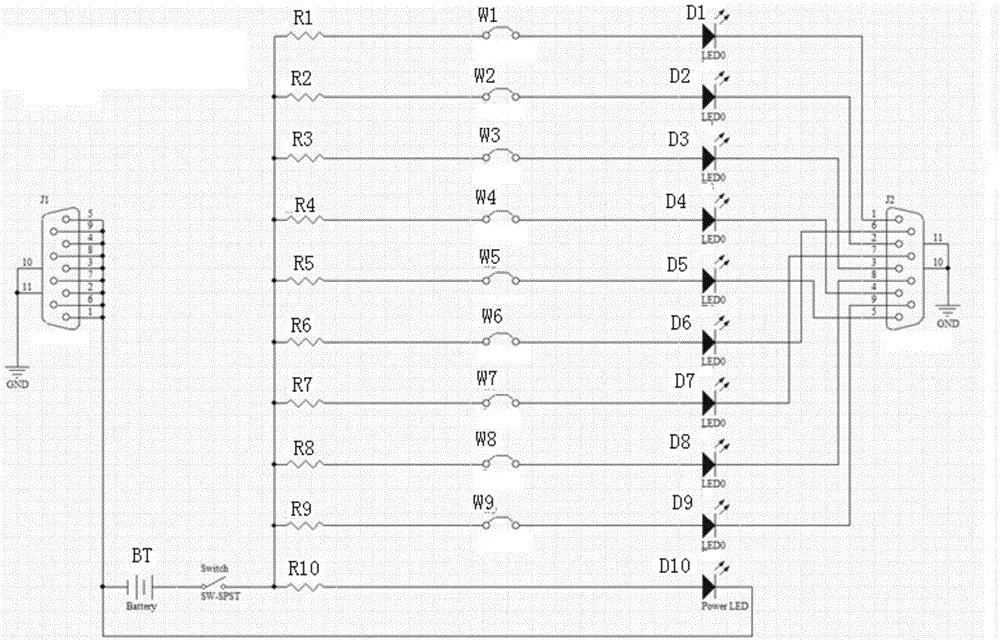

The invention relates to the field of wire correction devices, specifically a hand-held automatic wire correction device, and the device can be used for detecting a cable produced from a device manufacturer and detecting a cable during device debugging. The device is mainly used for detecting a cable of a D-Sub interface type. The device comprises a logic module which is used for on / off display and signal channel switching; two interface modules which are respectively disposed at two ends of the logic module and are used for providing different cable interfaces for different types of cables; a power supply module which is connected with the power supply end of the logic module and is used for providing power supply for an indicating lamp of the logic module. The device solves problems that the device manufacturer is low in detection efficiency of a purchased cable and is slow in measurement speed. Meanwhile, the device reduces the number of detection workers, saves a large amount of time and energy of a detection worker, and improves the fault inspection efficiency of the device.

Description

technical field [0001] The invention relates to the field of line calibration equipment, in particular to a hand-held automatic line calibration equipment, which can be used for inspection after cable processing by equipment manufacturers and for cable detection during equipment debugging. This equipment mainly detects cables with D-Sub interface. Background technique [0002] Professional automatic calibration equipment is often only used in professional cable manufacturers for product quality inspection. This kind of equipment is customized according to the cable manufacturer's own requirements. It uses PC+acquisition module for cable testing, and changes the testing program through the programmable interface to detect different types of cables. This kind of equipment is expensive, bulky, and the application occasions are mainly for cable processing manufacturers. [0003] At present, equipment manufacturers often use two people to hold one end of the cable connector in ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01R31/02

CPCG01R31/58

Inventor 梁立元

Owner PIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com