Automatic cotton straw collection device

A technology for automatic collection and cotton stalks, applied to harvesters, cutters, agricultural machinery and tools, etc., can solve problems such as high efficiency, fatigue, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

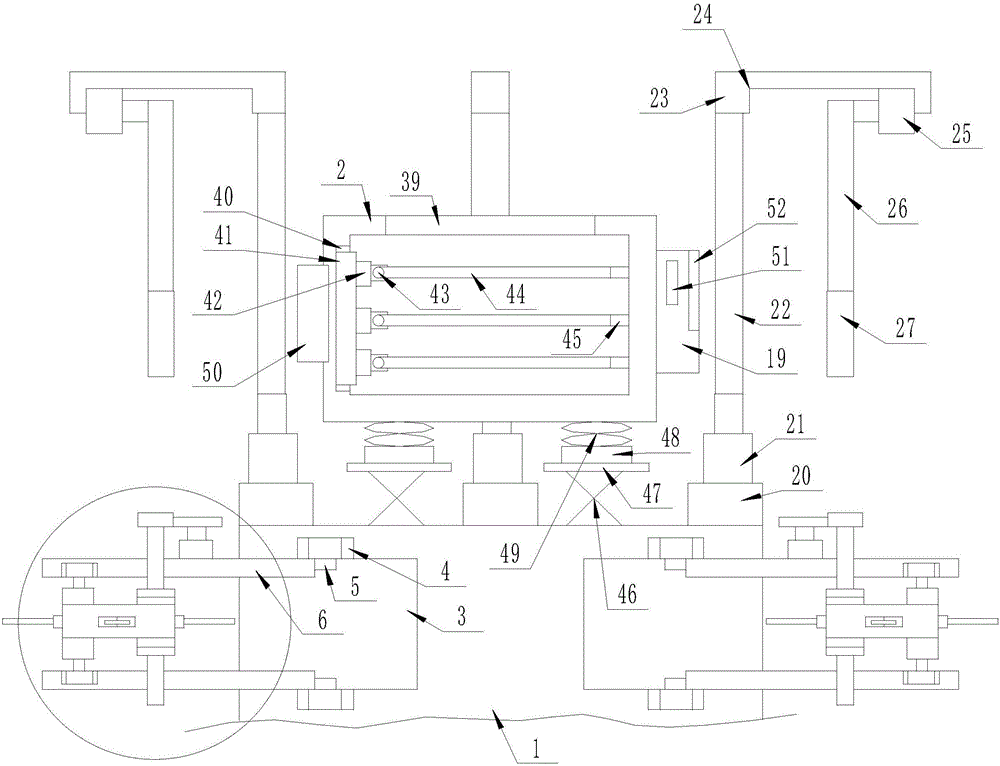

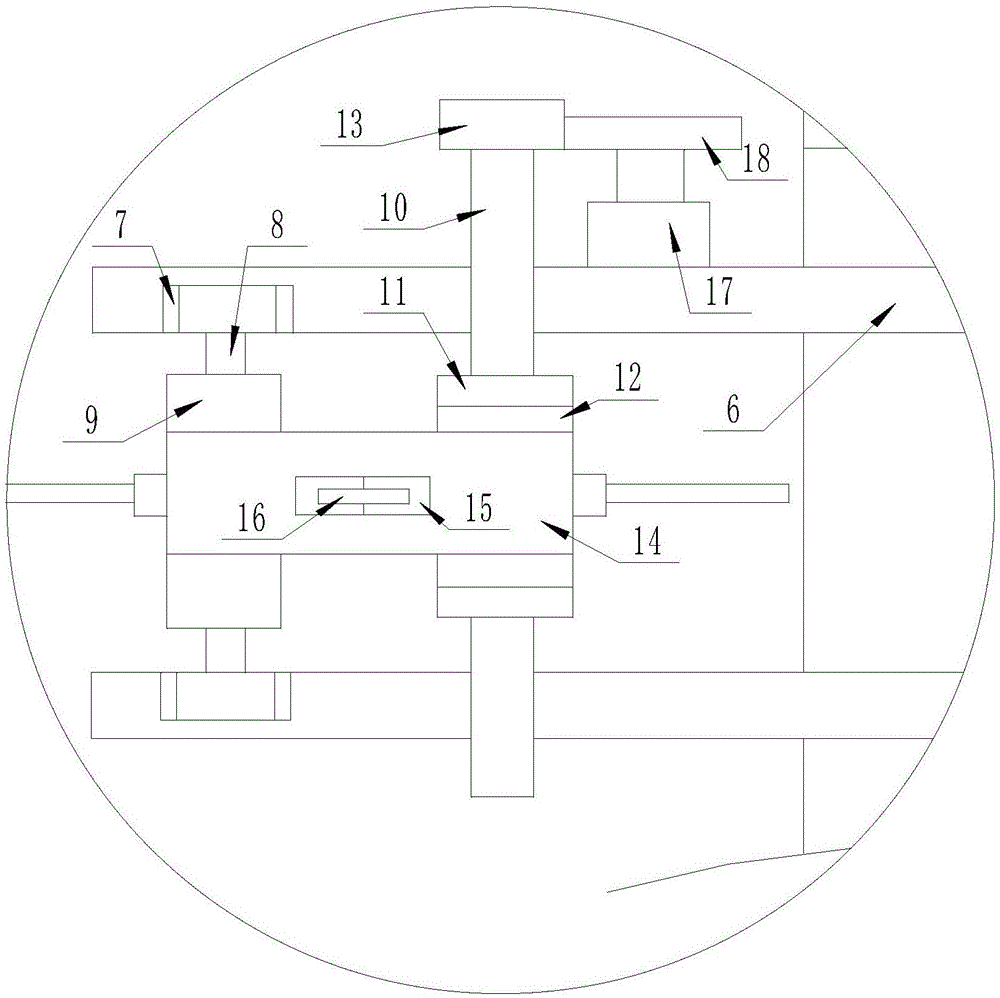

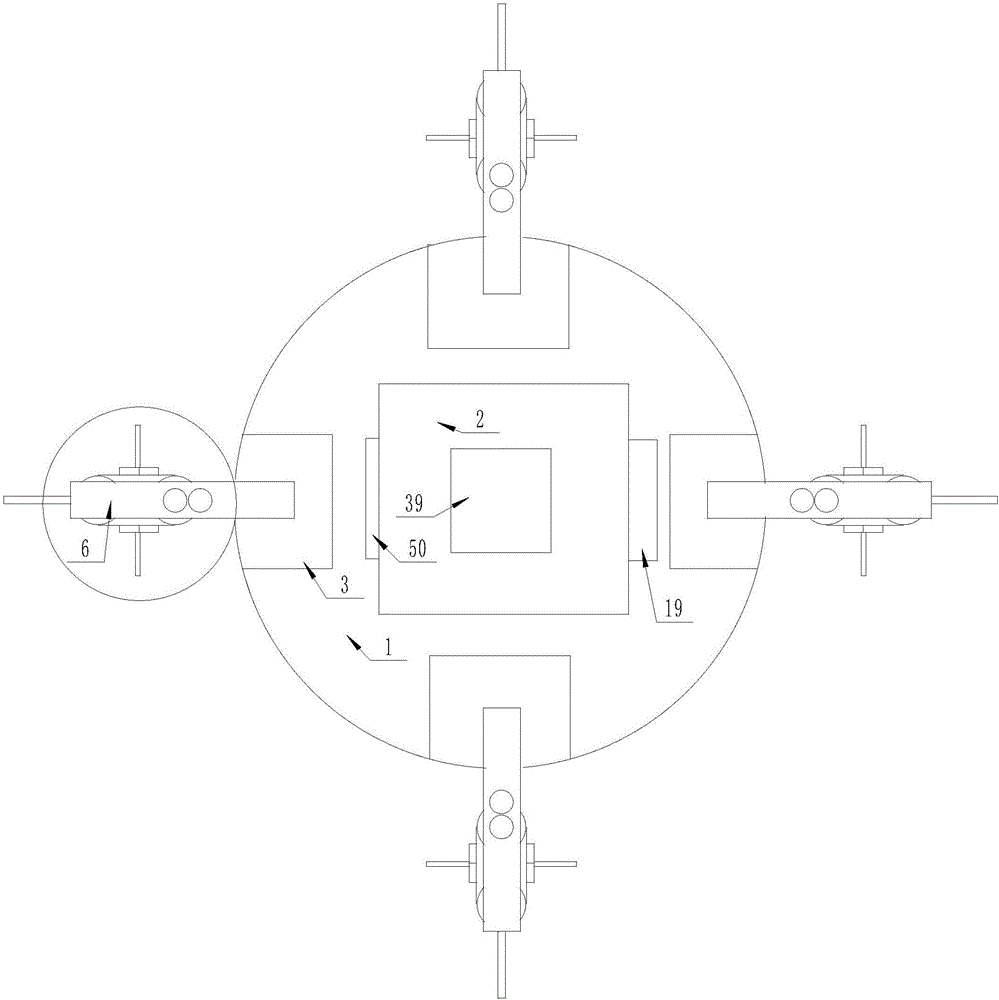

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5As shown, an automatic collection device for cotton stalks, comprising a circular base (1), a rectangular bearing barrel (2) is arranged above the circular base (1), and the circular base (1) and the rectangular A swing lifting mechanism is provided between the carrying buckets (2), a rotary cutting mechanism is provided on the side surface of the circular base (1), and a rotary cutting mechanism is provided on the edge of the upper surface of the circular base (1). The clamping mechanism for box overlap, the rectangular bearing barrel (2) is provided with a bearing mechanism, the lower surface of the circular base (1) is provided with a rotating walking mechanism, and the rotating cutting mechanism is opened on the circular base A plurality of No. 1 bar-shaped grooves (3) on the side surface of the seat (1), a group of No. 3 circular grooves (4) on the upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com