Air blowing type cooked egg shelling machine

A technology of boiled egg and shelling machine, which is applied in the direction of food science, can solve the problems of time-consuming and labor-consuming, and achieve the effect of preventing damage to protein and preventing axial rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

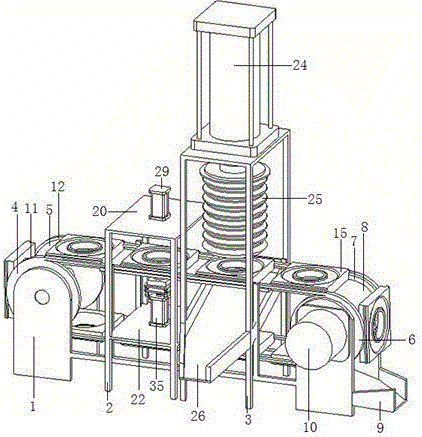

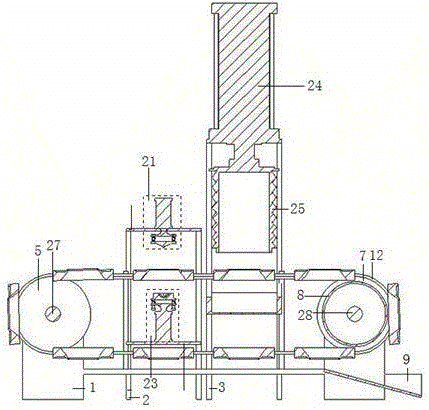

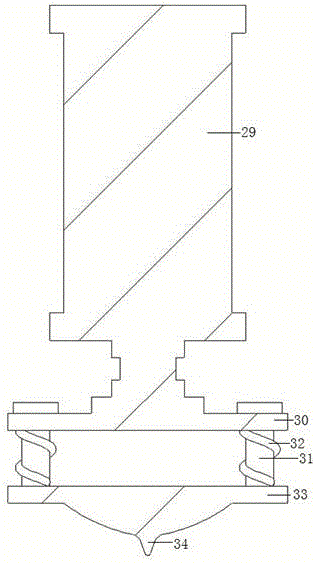

[0025] Specific embodiment 1: As shown in Figure 1-7, an air-blown boiled egg sheller includes a conveyor belt bracket 1, a shell breaking cylinder bracket 2 and an egg blowing cylinder bracket 3; the conveyor belt bracket 1 is installed on the front side of the left end A driven pulley 4 is arranged; a B driven pulley 5 is installed on the rear side of the left end of the conveyor belt support 1; A driving pulley 6 and B driving pulley 7 are welded with an eggshell plate 8 near the edge; the eggshell chute 9 is welded at the lower end of the eggshell plate 8; the outside of the right end of the conveyor belt bracket 1 is connected with a conveyor belt motor 10 by screws; A The A belt 11 is set on the driven pulley 4 and the A driving pulley 5; the B belt 12 is set on the B driven pulley 6 and the B driving pulley 7; the inside of the A belt 11 and the B belt 12 are equipped with mold pin holes 13; The pin hole 13 is equipped with a mold 15 through the mold pin 14; the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com