Aluminum furniture board

A furniture board and furniture technology, applied in furniture parts, home appliances, applications, etc., can solve the problems of inability to standardize production, high instability, and inability to overall film, and achieve the effect of easy standardized production and ingenious conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

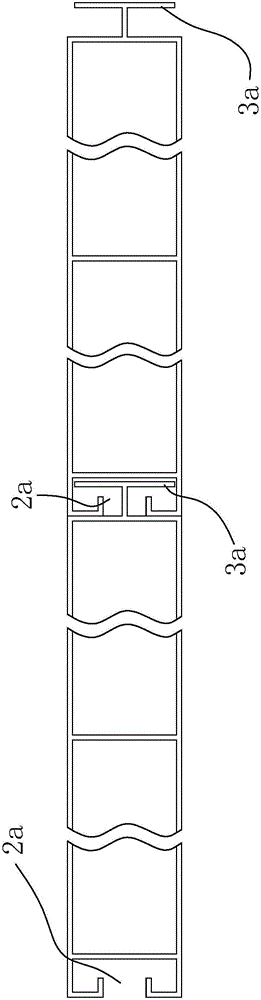

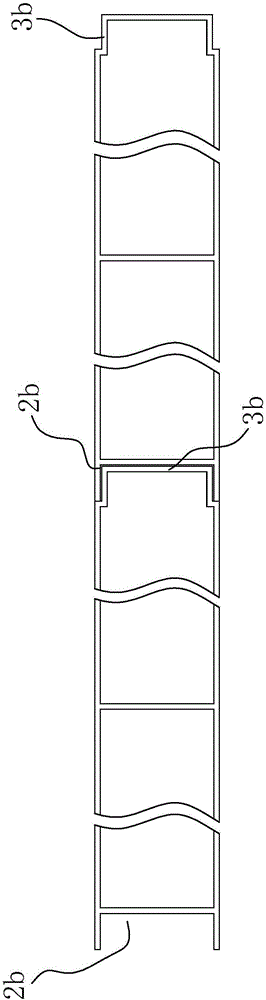

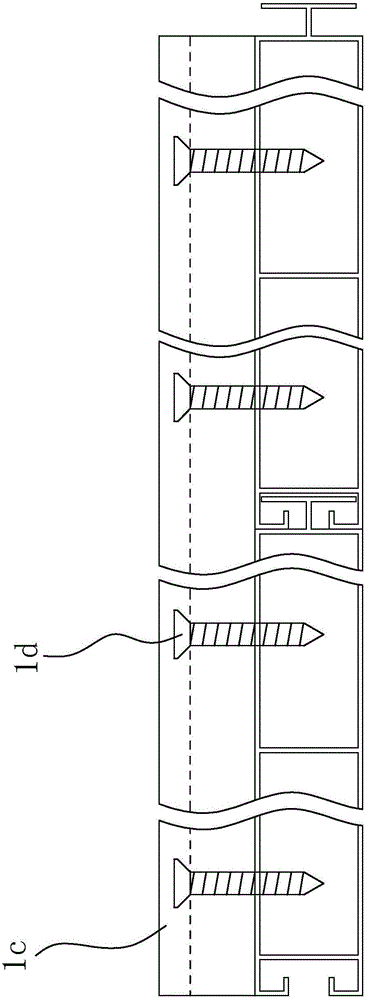

[0039] Here, refer to Figure 5 , to give an embodiment 1 that can make the left and right core strip profiles tightly hooked and produce a flat surface: the left hooking structure includes an upper left part and a lower left part, wherein the upper left part includes:

[0040] Left upper wing 11, which stretches to the left, and its upper surface is flush with the upper end surface of the core bar profile 1;

[0041] Left upper hook 12, which is located below the left upper wing 11, extends horizontally from the left end surface of the core bar profile 1 to the left, and the left end section is provided with a left upper barb 121;

[0042] The right hooking structure includes an upper right part and a lower right part, wherein the upper right part includes:

[0043] The upper right wing 13 stretches to the right, the upper surface is flush with the upper end surface of the core bar profile 1, the end of the upper right wing 13 is slightly bent downward to form an embedded se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com