Hollow nano-activated carbon rod and preparation method thereof

A technology of nanometer activated carbon and powdered activated carbon, which is applied in the field of filter materials, can solve the problems of short COD removal life, easy powder removal, disintegration, low strength and hardness, etc., and achieves the effect of inhibiting bacterial growth, good synergistic effect and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

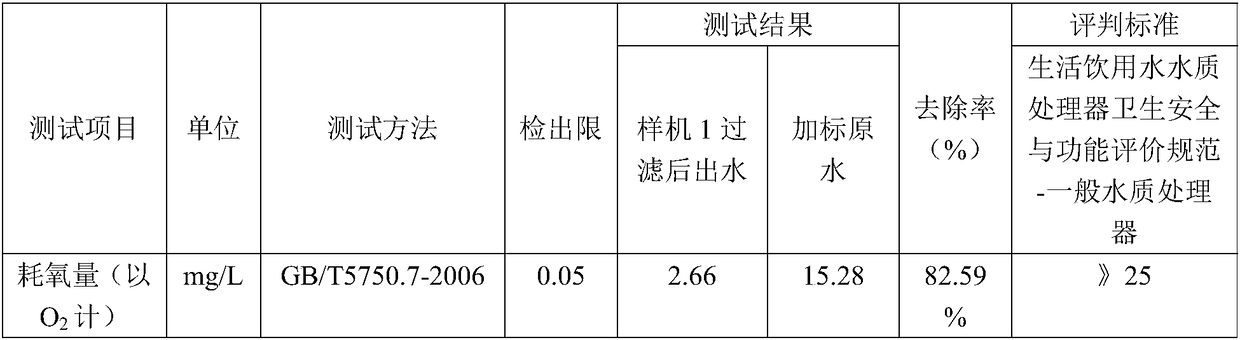

Embodiment 1

[0016] Preparation of hollow nano activated carbon rods

[0017] Prepare 80 mesh 2000g powdery attapulgite decolorizing adsorbent (purchased from Mingguang Guoxing Attapulgite Co., Ltd., model is GF-2 type), 60 mesh 4000g powdered activated carbon (purchased from Zhengzhou Huihuang Tongda Water Treatment Co., Ltd. Material Co., Ltd.), 200 mesh 3000g polyethyl acetate glue (purchased from Foshan Yide Adhesive Co., Ltd., model EVA640), and then put the prepared powdery attapulgite, powdery activated carbon and powdery rubber powder into the vacuum Drying machine (purchased from Taicang Kailing Drying Equipment Factory, model 10) carries out synchronous mixing and stirring and uniform drying in the vacuum chamber, the drying temperature is 80 ° C, and the vacuum pressure is 8 MPa to obtain the dried product, and then the obtained The dried material is sent to the hopper of the extrusion molding machine (purchased from Jiangsu Jinwo Machinery Co., Ltd., model JWP-20), the extrusio...

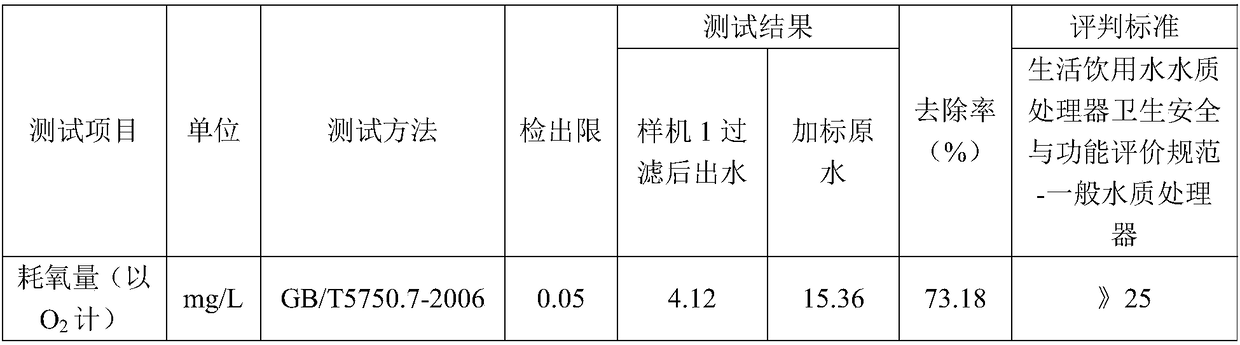

Embodiment 2

[0019] Preparation of hollow nano activated carbon rods

[0020] Prepare 280 mesh 6000g attapulgite decolorizing adsorbent (purchased from Mingguang Guoxing Attapulgite Co., Ltd., model is GF-1 type), 300 mesh 9000g powdered activated carbon (purchased from Zhengzhou Huihuang Tongda Water Treatment Material Co., Ltd.) , 600 mesh 7500g polyethyl acetate glue (purchased from Foshan Yide Adhesive Co., Ltd., model EVA640), then put the prepared powdery attapulgite, powdery activated carbon and powdery rubber powder into the vacuum dryer vacuum Carry out synchronous mixing and stirring in the warehouse for uniform drying, the drying temperature is 40°C, and the vacuum pressure is 12MPa to obtain the dried product, and then the obtained dried product is sent to the hopper of the extrusion molding machine, and the extrusion molding machine is started Let the dried material in the hopper leak into the main machine, extrude the raw material into a hollow rod-shaped primary product thro...

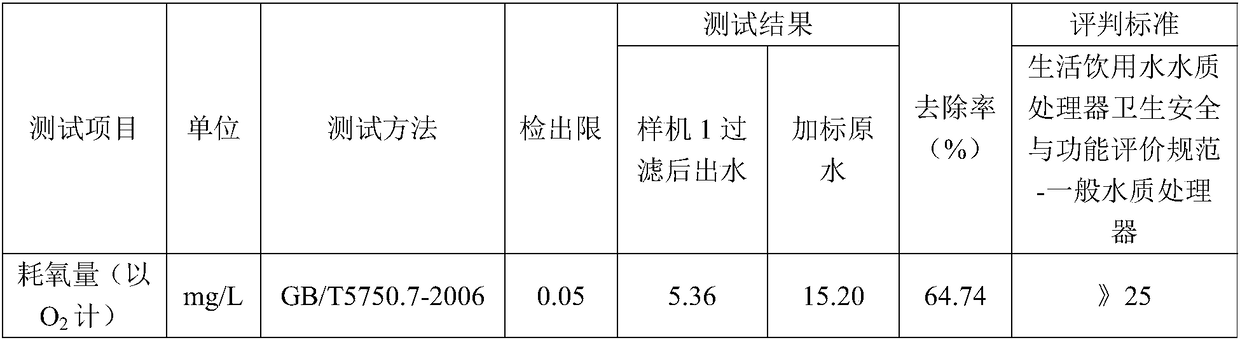

Embodiment 3

[0022] Preparation of hollow nano activated carbon rods

[0023] Prepare 100 mesh 3000g attapulgite decolorizing adsorbent (purchased from Mingguang Guoxing Attapulgite Co., Ltd., model is GF-2 type), 80 mesh 6000g powdered activated carbon (purchased from Zhengzhou Huihuang Tongda Water Treatment Material Co., Ltd.) , 500 mesh 4500g polyethyl acetate glue (purchased from Foshan Yide Adhesive Co., Ltd., model EVA640), then put the prepared powdery attapulgite, powdery activated carbon and powdery rubber powder into the vacuum dryer vacuum Carry out synchronous mixing and stirring in the warehouse for uniform drying, the drying temperature is 65°C, and the vacuum pressure is 10MPa to obtain the dried product, and then the obtained dried product is sent to the hopper of the extrusion molding machine, and the extrusion molding machine is started Let the dried material in the hopper leak into the main machine, extrude the raw material into a hollow rod-shaped primary product throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com