Coagulation-enhanced type cyclone dedusting and demisting device

A defogging device and an enhanced technology, which are applied in the fields of combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of poor separation efficiency, rising investment and operating costs, and difficulty in meeting the emission requirements of the demister. The effect of reducing investment and operating costs, reducing the number of swirl components, and improving collectability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

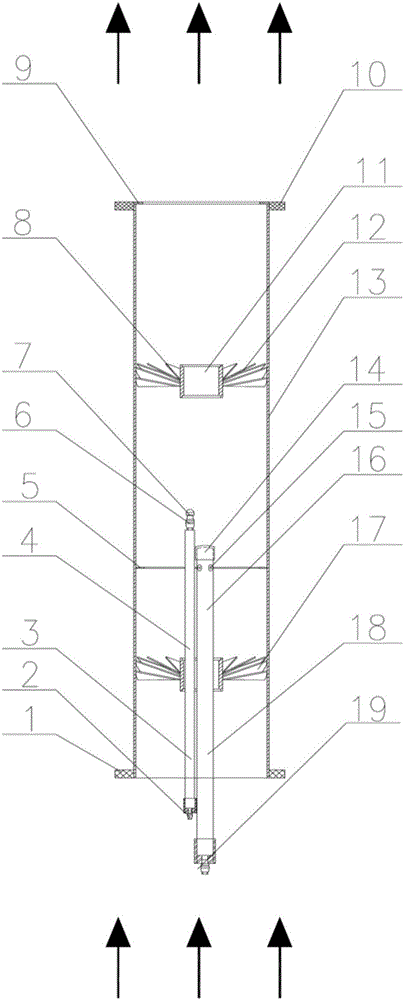

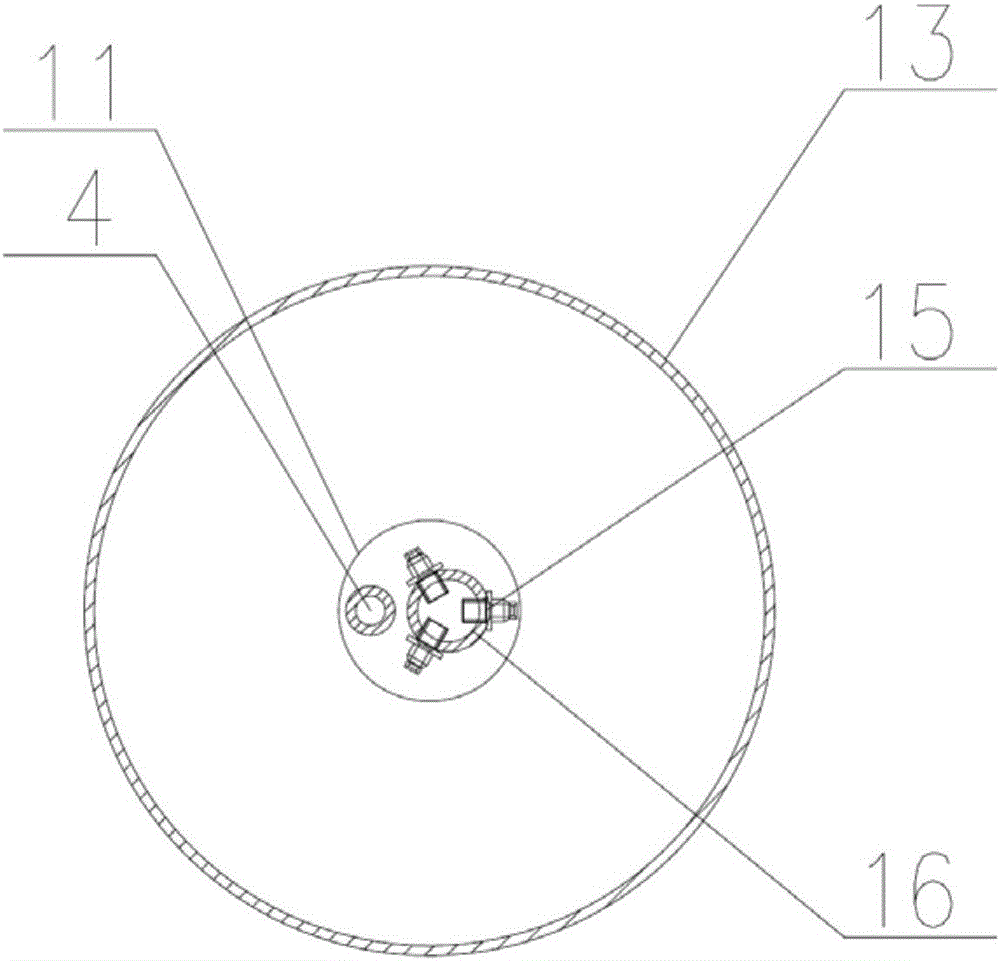

[0033] A condensing and enhanced cyclone dust and mist removal device, the device includes a cylindrical outer cylinder (13), m swirl assemblies (8), and the swirl assemblies (8) include several swirl blades (12) and a central cylinder (11), the swirl blades (12) are evenly distributed in the annular area between the outer wall of the central cylinder (11) and the inner wall of the cylindrical outer cylinder (13) at an inclined angle, the swirl The number of flow components m≥2;

[0034]An n-stage condensing device (4) is provided in the cylindrical outer cylinder (13) between at least one group of connected cyclone components (8), and the condensing device (4) includes a condensate pipeline (3) And the nozzle (7) which is arranged on the top of the condensate pipeline (3) to generate the droplet particle size of 2-80 μm and the quick joint (2) of the condensate device arranged at the bottom of the condensate pipeline (3), the condensate The device quick connector (2) is conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com