Synergetic purifying device for removing pollutants in flue gas of glass kiln

A glass furnace and purification device technology, applied in furnaces, furnace components, gas treatment, etc., can solve the problems of large operating pressure loss, low melting point of smoke and dust, strong viscosity, etc., to improve capture performance, improve denitrification efficiency, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

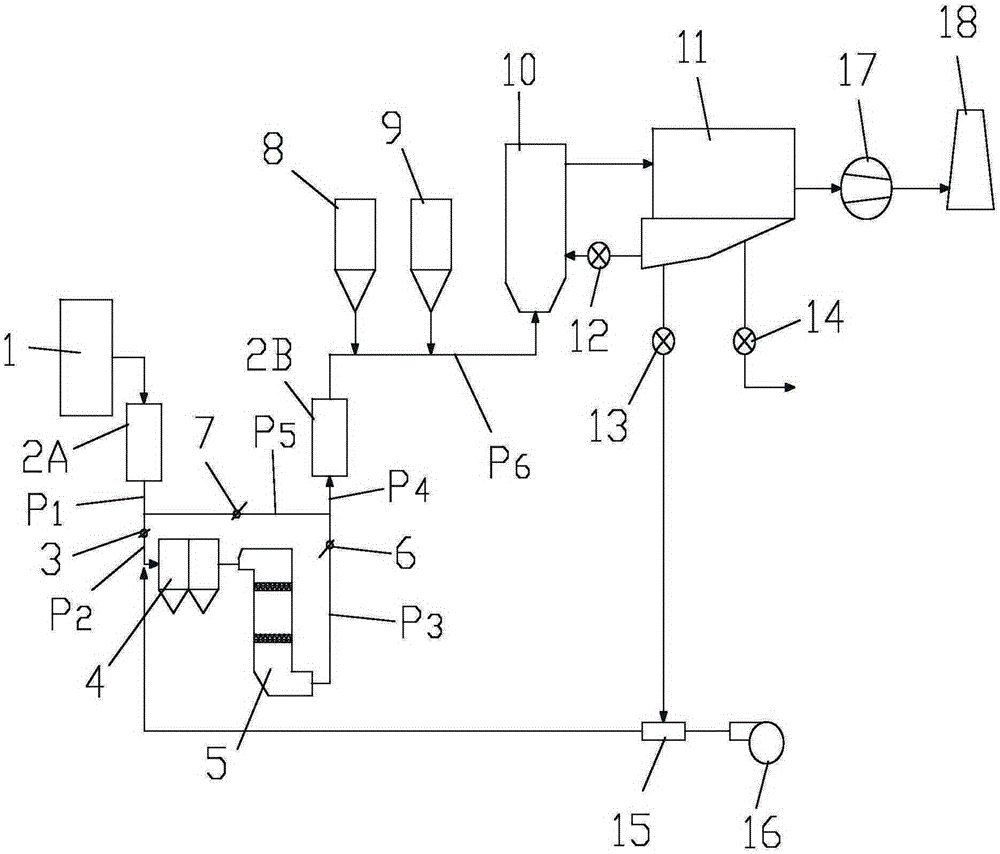

[0024] Such as figure 1 Shown is a preferred embodiment of a glass furnace flue gas pollutant collaborative purification device of the present invention, the glass furnace flue gas pollutant collaborative purification device mainly includes a waste heat boiler, an electric precipitator 4, an SCR denitrification reactor 5, a Na 2 CO 3 Feeding device 8, desulfurization agent dosing device 9, desulfurization reactor 10, desulfurization dust collector 11, ash circulation metering device 12, ash conditioning metering device 13, ash injector 14, blower 15 and ash discharge valve 16.

[0025] Wherein, the waste heat boiler includes a high-temperature side 2A and a low-temperature side 2B, the inlet of the high-temperature side 2A is connected with the outlet of the glass furnace 1, the outlet of the high-temperature side 2A is connected with the inlet of the electrostatic precipitator 4, and the outlet of the electrostatic precipitator 4 is connected with the The inlet of the SCR de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com