Spraying equipment cleaning tool

A technology for cleaning tools and spraying equipment, applied in the direction of spraying devices, etc., can solve the problems of high cost and low service life, and achieve the effects of long service life, low manufacturing cost, and simple and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

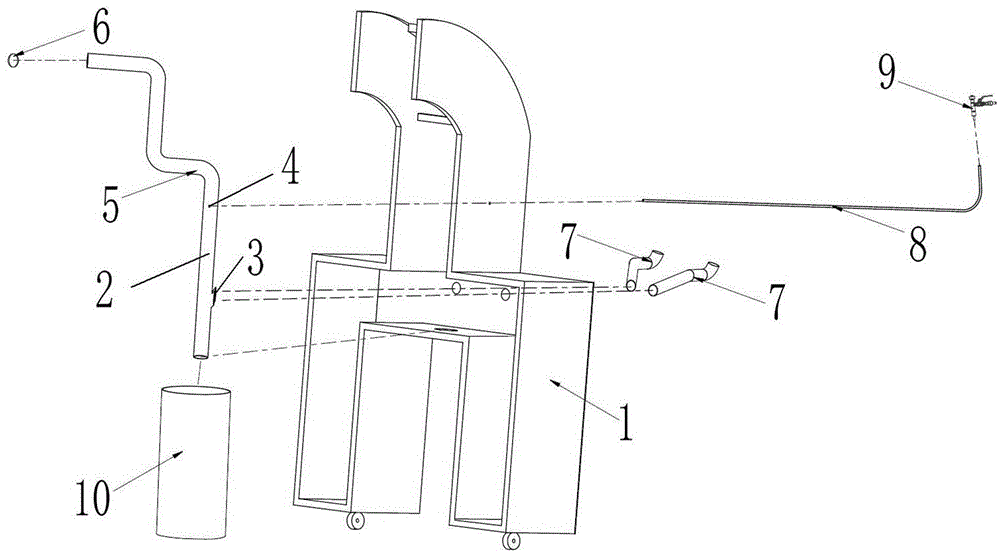

[0019] Attached below figure 1 The present invention will be further described.

[0020] A cleaning tool for spraying equipment, comprising: an exhaust port 6 connected to the workshop ventilation duct, an air duct 2, a connecting pipe 7 and an air intake duct 8, the upper end of the air duct 2 is connected to the air exhaust port 6, and the lower end is connected to the waste liquid bucket 10 connected, the air pipe 2 is provided with the liquid inlet 3, the tail end of the connecting pipe 7 is connected with the liquid inlet 4, the paint spray gun is inserted into the mouth of the connecting pipe 7 head end, the air pipe 2 is located at the liquid inlet 3 An air inlet 4 is arranged above, the tail end of the air inlet pipe 8 is connected to the air inlet 4, and the head end thereof is connected to the air compressor through a shut-off valve 9 . When in use, open the shut-off valve 9, compressed air enters the air duct 2 through the intake pipe 8, insert the spray gun into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com