Weight checking machine

A checkweigher and checkweighing technology, applied in the direction of continuous material flow weighing equipment, instruments, sorting, etc., can solve the problems affecting the checkweighing accuracy, the damage of the motor balance of the checkweighing, etc. Simple structure and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

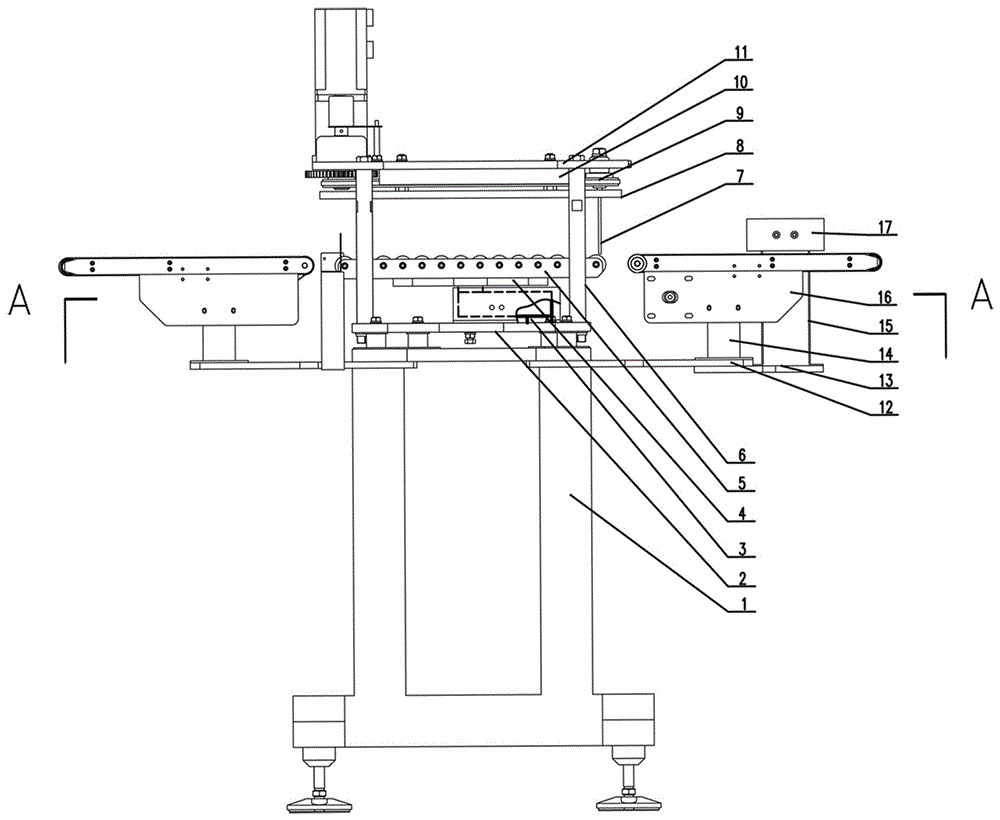

[0011] see figure 1 and figure 2 , the embodiment of a kind of checking weighing machine described in the present invention, a set of checking weighing mechanism, material shifting mechanism and rejecting mechanism are installed on the frame 1 (such as figure 1 shown).

[0012] The checkweighing mechanism is installed on the upper plane of the frame 1 for detecting the weight of the product delivered; At the output end of the rack, it is used to reject unqualified products.

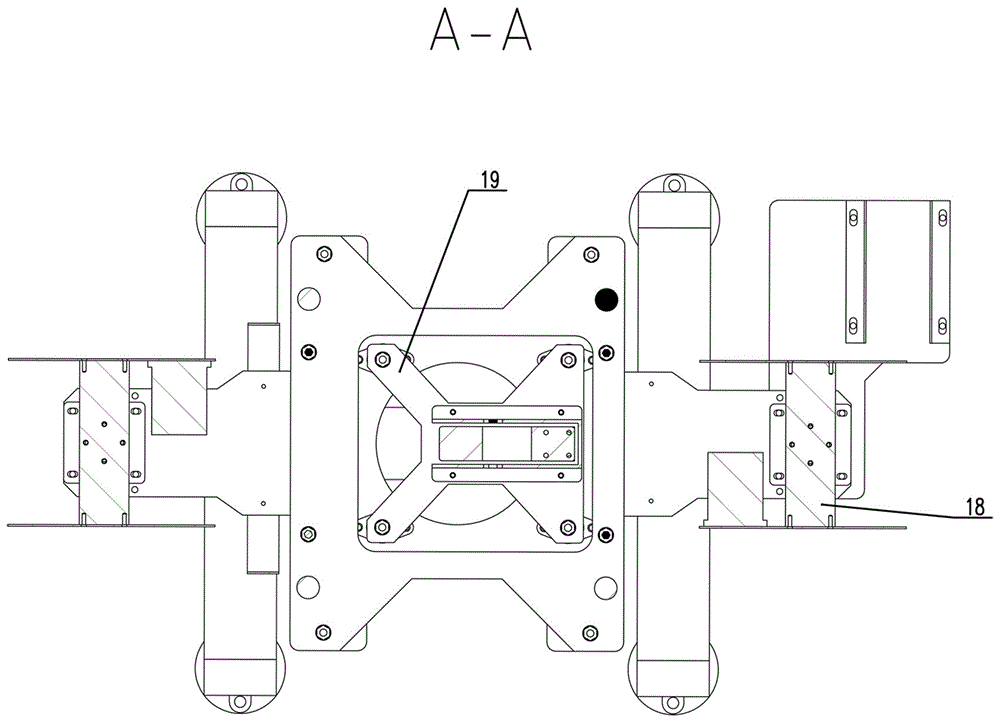

[0013] The weighing mechanism includes an induction module supporting plate 19, a backing plate 3, a pulley block supporting plate 4, and a pulley block 5. The sensing module supporting plate 19 is installed on the middle and upper end of the frame 1; the backing plate 3 is installed on the sensing module The upper plane of the supporting plate 19; the pulley block supporting plate 4 is installed on the backing plate 3; the pulley block 5 is installed on the pulley block supporting plate 4.

[0014] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com