Middle roll-over table of automatic stamping mechanical hand

A technology of turning table and manipulator, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problem of turning angle and other problems, and achieve the effect of improving utilization rate and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

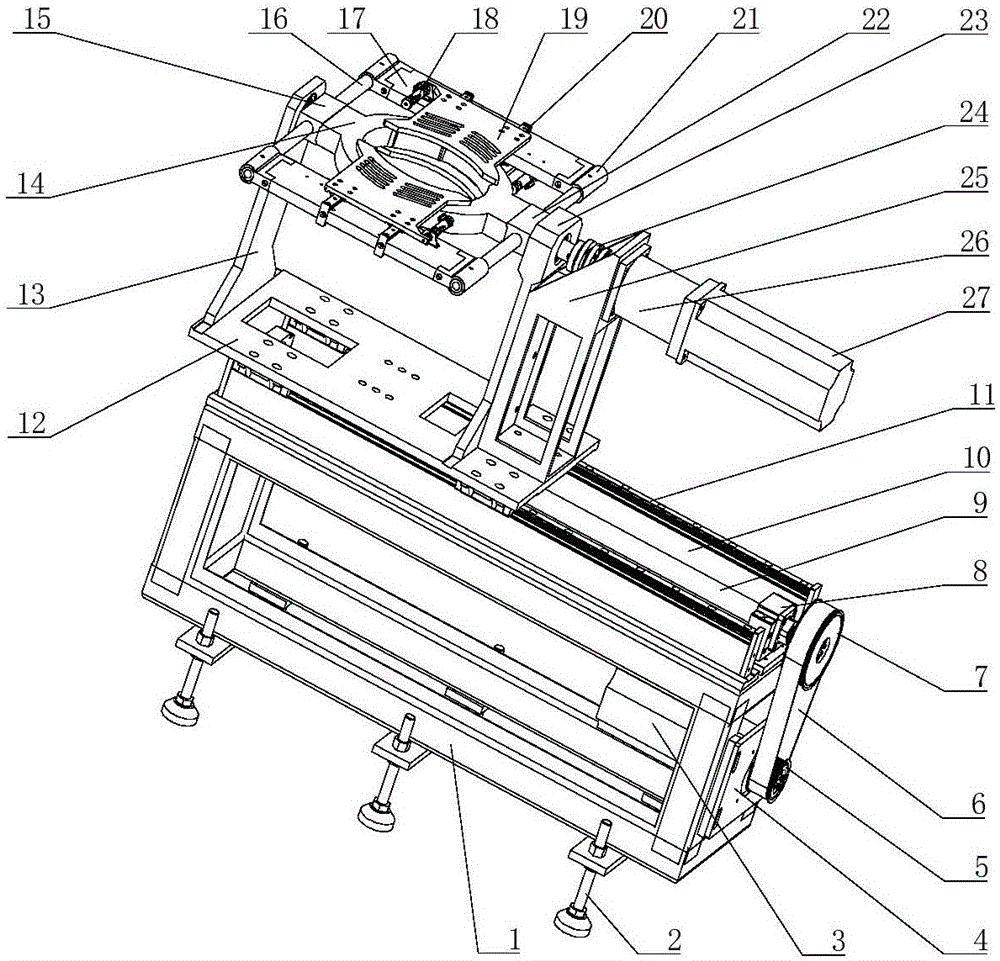

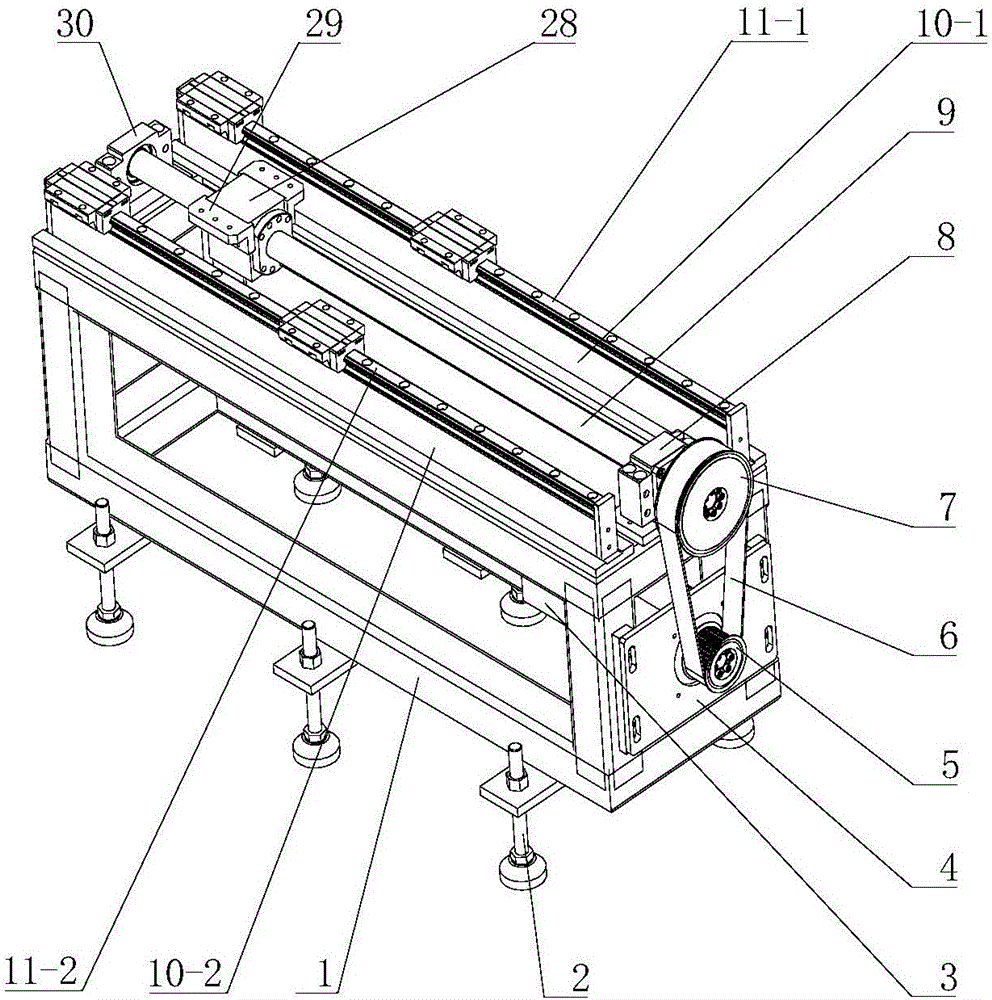

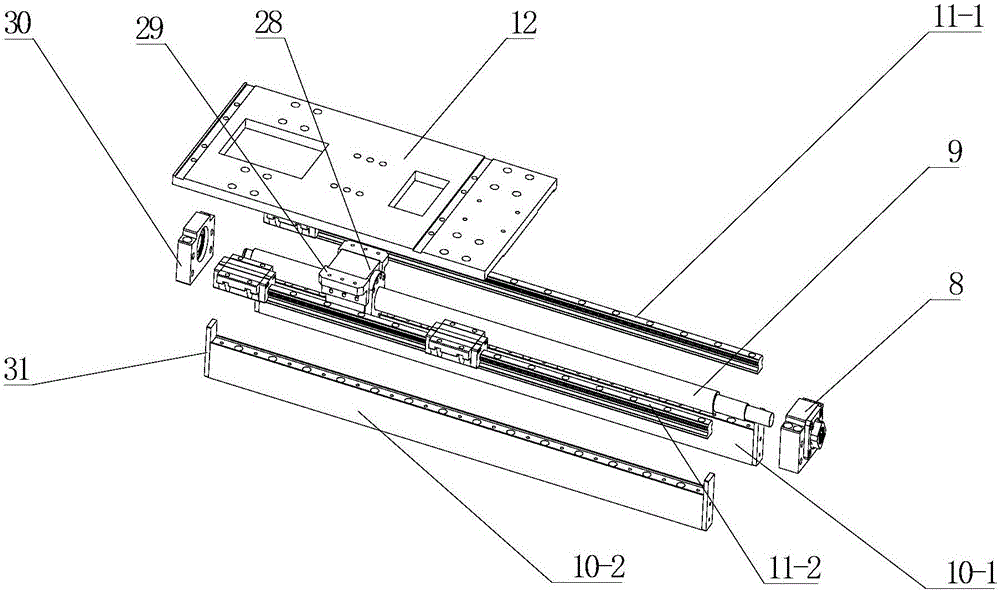

[0020] Such as figure 1 As shown, the middle turning table includes a base 1 welded by profiles, and the bottom of the base 1 is provided with an adjustable pad 2 that can effectively adjust the height of the turning table. By adjusting the nut position of the adjusting foot pad 2, the height of the middle turning table can be adjusted. One side of the base 1 is threadedly connected with a motor mounting plate 4, and the motor mounting plate 4 is provided with a vertical strip hole. By adjusting the position of the strip hole up and down, the timing belt 6 can be tensioned, and the motor mounting plate 4 is connected by bolts. There is a first servo motor 3, the output end of the first servo motor 3 is connected to the small synchronous wheel 5 through a flat key, the small synchronous wheel 5 is connected to the large synchronous wheel 7 through a synchronous belt 6, and the large synchronous wheel 7 and the ball screw 9 are also connected through Flat key connection, when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com