Pipe pile welding robot

A welding robot and pipe pile technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of low degree of automation, and achieve the effect of improving welding quality, stable and reliable welding quality, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

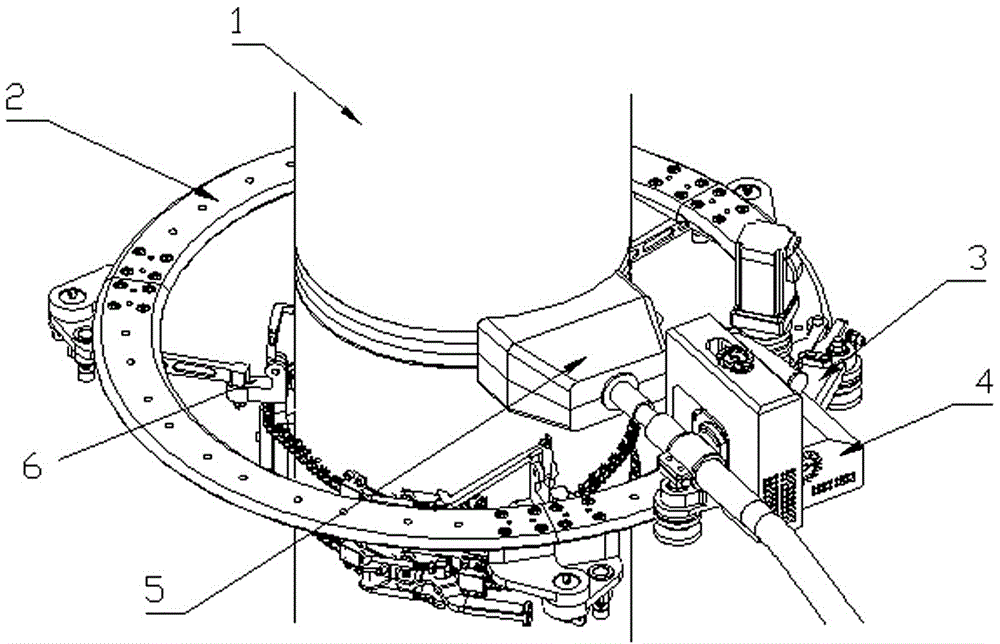

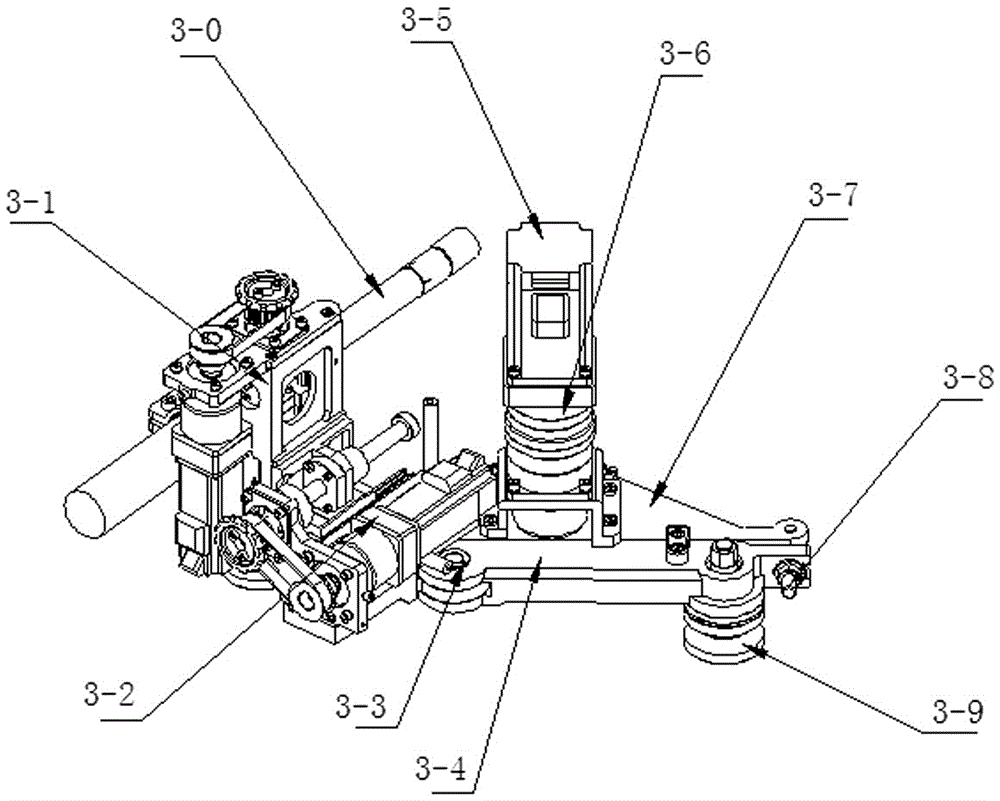

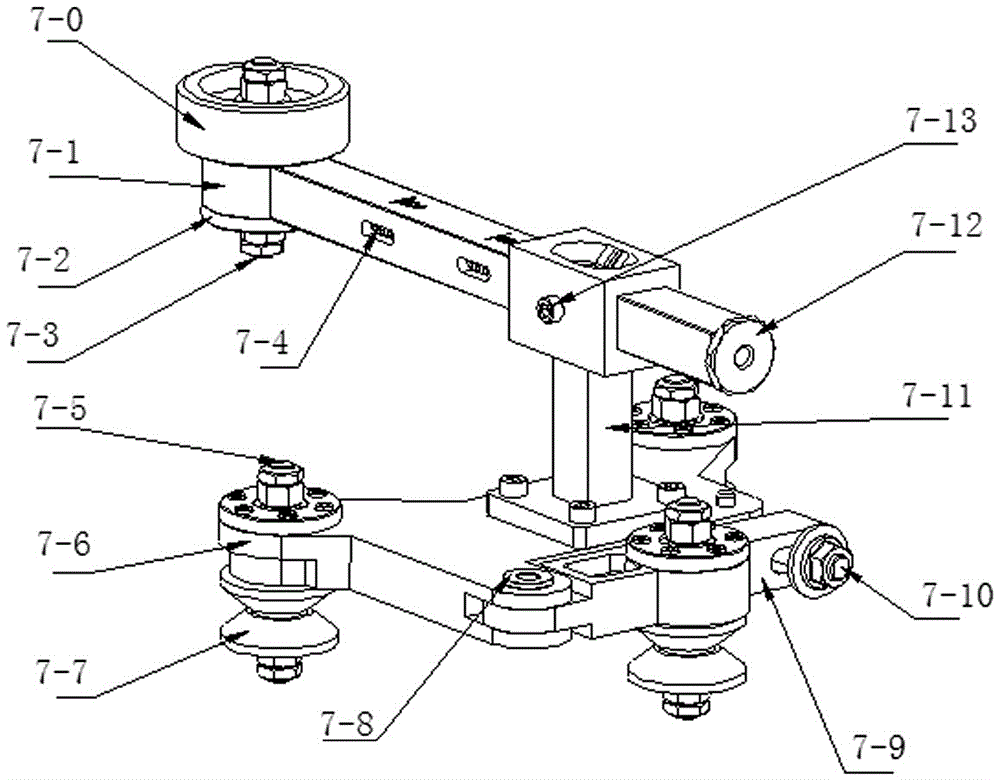

[0023] The following will be combined with Figures 1 to 8 A detailed introduction to the present invention: the present invention includes a trolley welding platform 3, a track mechanism 2, a support mechanism 6, and a calibration mechanism 7. The support mechanism 6 is composed of three sets of support members, which are roughly distributed at 120°, and are composed of chains 8 And buckle 9 is fixed on the circumferential surface of pipe pile body 1. The chain 8 and the buckle 9 cooperate with the supporting mechanism 6 through the pressing plate 6-4, the supporting plate 6-5. The track mechanism 2 is arranged on the support mechanism 6, and the degree of freedom is fixed and limited by means of tightening screws 6-3, latches 2-4, etc., and then fixed and tightened after the concentricity and height are finally calibrated. The height of the track 2-1 and the welding station is calibrated by the vertical A scale 6-7 and the vertical B scale 6-8, so that the distance variatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com