Reinforcement cage stirrup end tip compressing welding device for modern prefabricated constructional engineering

A technology of construction engineering and welding equipment, which is applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high labor intensity, low work efficiency, and difficult control of the thickness of the protective layer of steel bars, so as to save labor and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the embodiments and drawings.

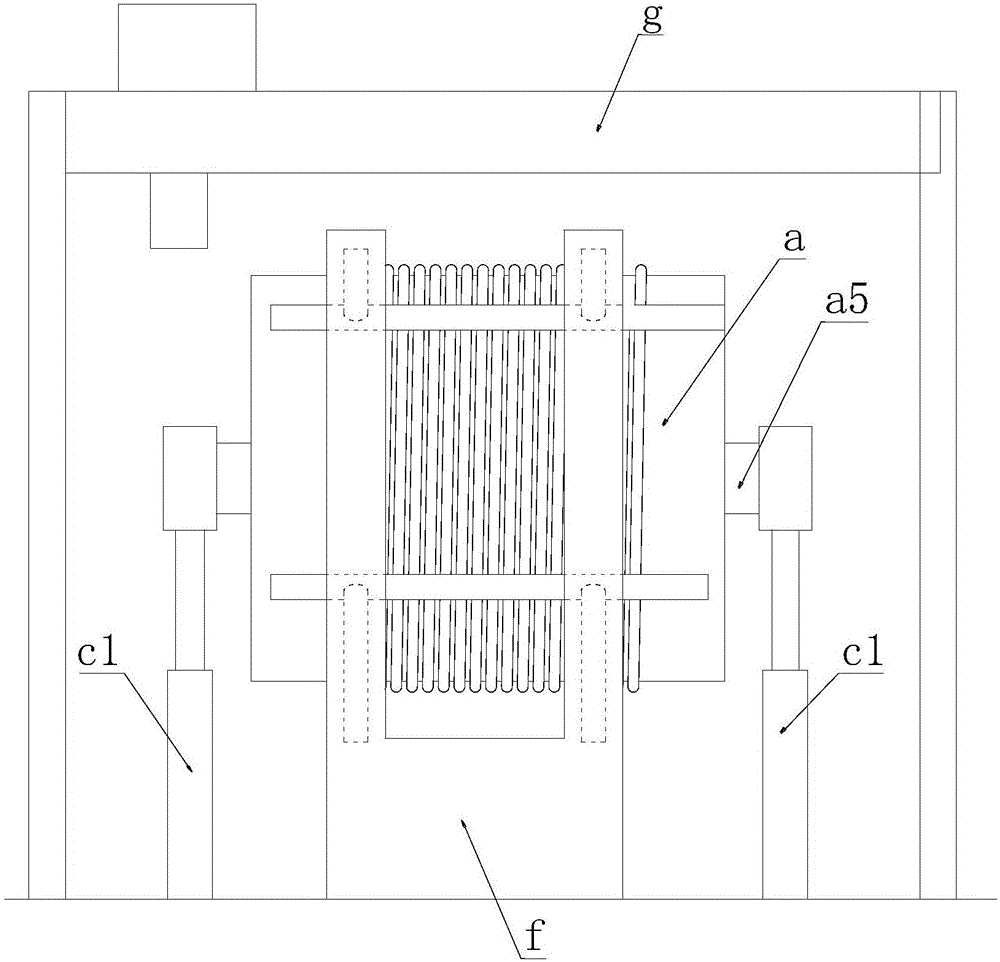

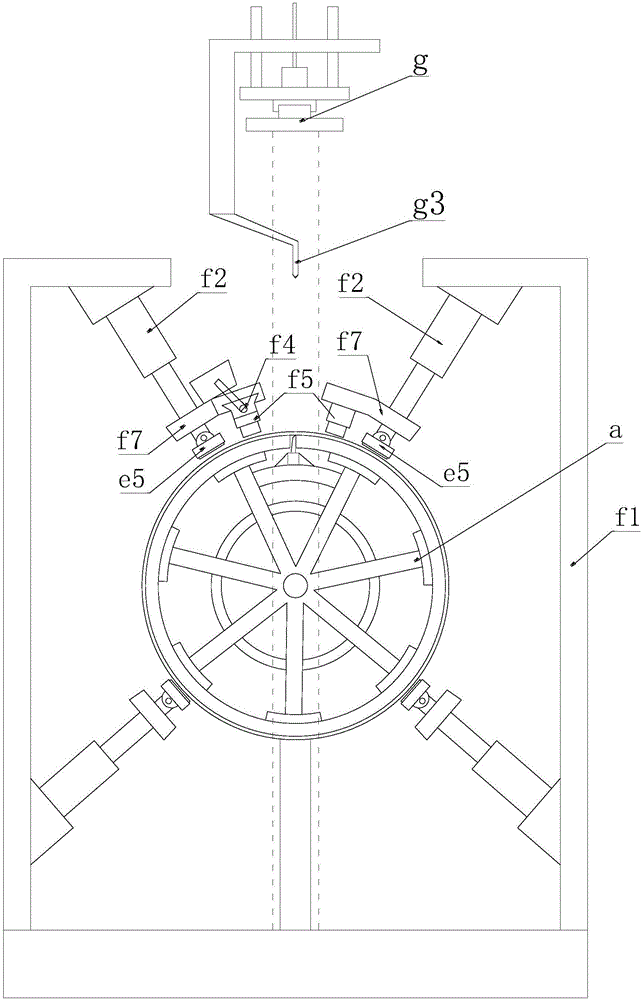

[0039] Such as Figure 1 to Figure 13 As shown, a modern prefabricated construction engineering reinforcement cage stirrup end compression welding device includes a base on which a spiral reinforcement winding component a, a stirrup compression clamping component f and an end welding Component g;

[0040] The spiral rib winding assembly a includes two winding supports c1 that are arranged opposite each other, a winding cylinder is installed between the two winding supports c1, and the winding cylinder includes a cylinder a1, and the cylinder a1 A cylinder shaft a5 is penetrated inside, and two ends of the cylinder shaft a5 are respectively movably connected with the two winding supports c1;

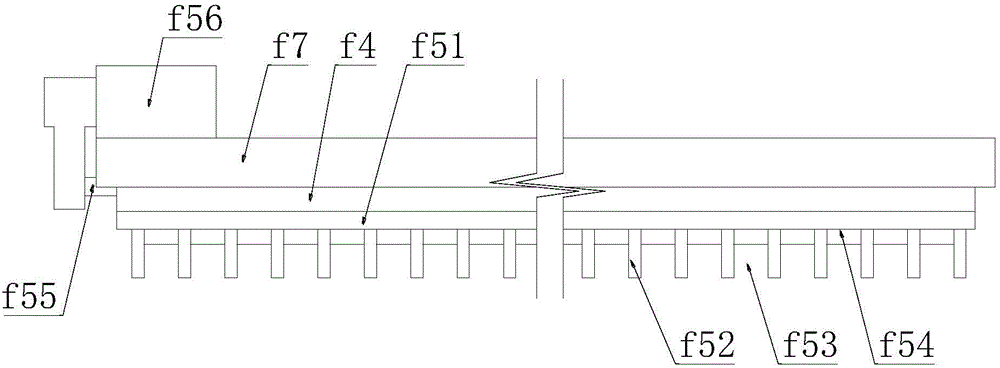

[0041] The stirrup pressing and clamping assembly f includes support members f1 respectively arranged on the base, the support members f1 are provided with two telescopic members f2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com