Double-tool-magazine machining center

A machining center and double tool magazine technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of reduced work efficiency and slow tool change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

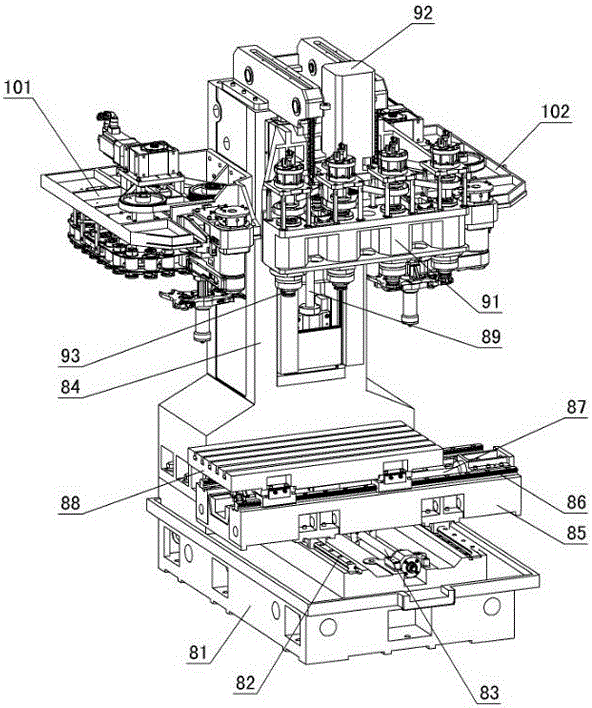

[0021]The present invention relates to a machining center with double tool magazines, as shown in Fig. 1-Fig. The cross slide 85 is set on the rail, the lower end of the cross slide is matched with the Y-direction screw, and the Y-direction screw is driven to rotate by power. The X-direction line rail 86 and the X-direction screw 87 are set on the cross slide. Table 88, the lower end of the workbench cooperates with the X-direction screw 87, the X-direction screw is driven to rotate by power, the workpiece is set on the workbench, the column screw 89 is set in the column 84, and the lifting block 90 is set on the column screw to lift Block front side connects main shaft box 91, is provided with main shaft servomotor 92 and 4-8 with main shaft 93 on main shaft box, the output shaft of main shaft servo motor connects two main shaft belt pulleys 94 up and down, main shaft driven wheel 95 is set respectively on each main shaft, up and down Two main shaft pulleys 94 respectively dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com