Precast beam hydraulic opening self-traveling formwork and self-travelling method

A prefabricated beam and formwork technology, applied in the direction of manufacturing tools, mold auxiliary parts, unloading devices, etc., can solve the problems affecting the concrete strength of the beam body, the separation of the side formwork and the bottom formwork, affecting the appearance quality of the beam body, etc., to save transportation. The effect of cost, reduced investment, convenient and quick construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

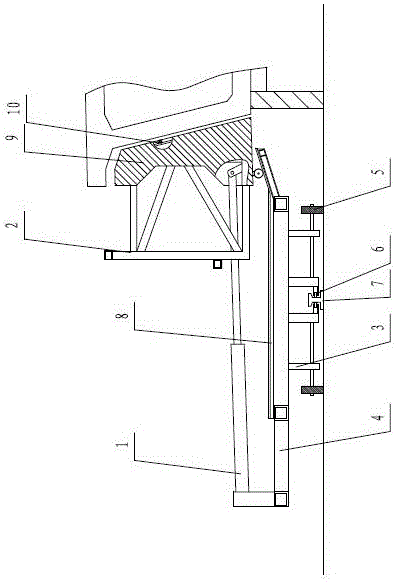

[0027] A prefabricated beam hydraulically opened self-propelled formwork, which consists of: a support block 3, a hydraulic device 1 and a formwork frame 2, the car body of the support block is a rectangular support body 4 structure formed by welding shaped steel, and the The shaped steel on both sides of the lower end of the rectangular support body is connected with a walking wheel 5, and the middle position of the lower end of the rectangular support body is connected with a guide wheel 6 between the shaped steel, and the described guide wheel is installed on the inside of the horizontal track 7, The upper end of the support block is provided with a slideway 8, and the template frame is installed in the slideway through traveling wheels.

Embodiment 2

[0029] According to the prefabricated beam described in Embodiment 1, the self-propelled formwork is hydraulically opened, one end of the formwork frame is connected to the formwork 9 through a bolt assembly 10, and the other end is connected to the hydraulic device, and the hydraulic device is installed on the Support the upper part of the tackle,

Embodiment 3

[0031] According to the prefabricated beam described in embodiment 1 or 2, the self-propelled formwork is hydraulically opened, and the connection between the hydraulic device and the formwork frame is connected by a rotating shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com