T-bag bag making process and equipment

A kind of technology of equipment and molding machine, which is applied in the direction of bag making, flexible container manufacturing, paper/cardboard container, etc. It can solve the problems of uncoordinated, cumbersome gear teeth changing, difficulty in adapting to the production of T-shaped bags of various sizes, etc. Achieve the effect of precise folding process and high-speed continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

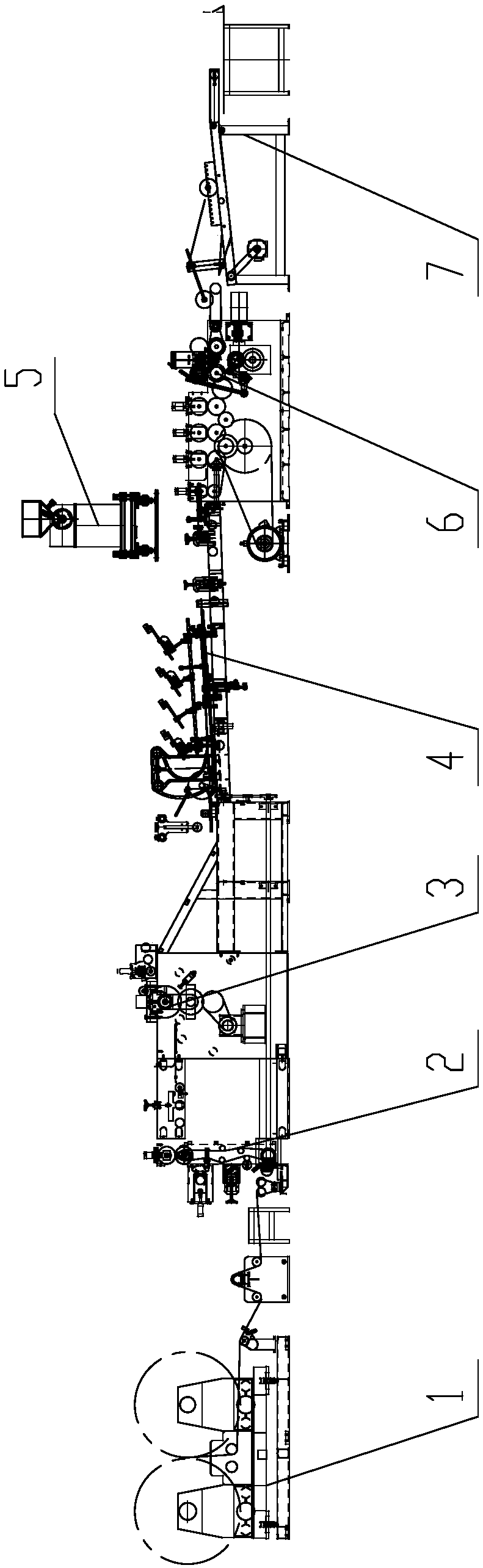

[0055] Such as figure 1 As shown, a T-shaped bag-making equipment includes a double-station cloth constant tension unwinding machine 1, a hoist 2, a T-shaped cutting machine 3, a forming machine 4, a middle seam extruder 5, and a servo tearing machine 6 And bag collecting machine 7, double-station cloth constant tension unwinding machine 1, elevator 2, T-shaped cutting machine 3, forming machine 4, middle seam extruder 5, servo tearing machine 6 and bag collecting machine 7, in order Connected placement becomes a production line.

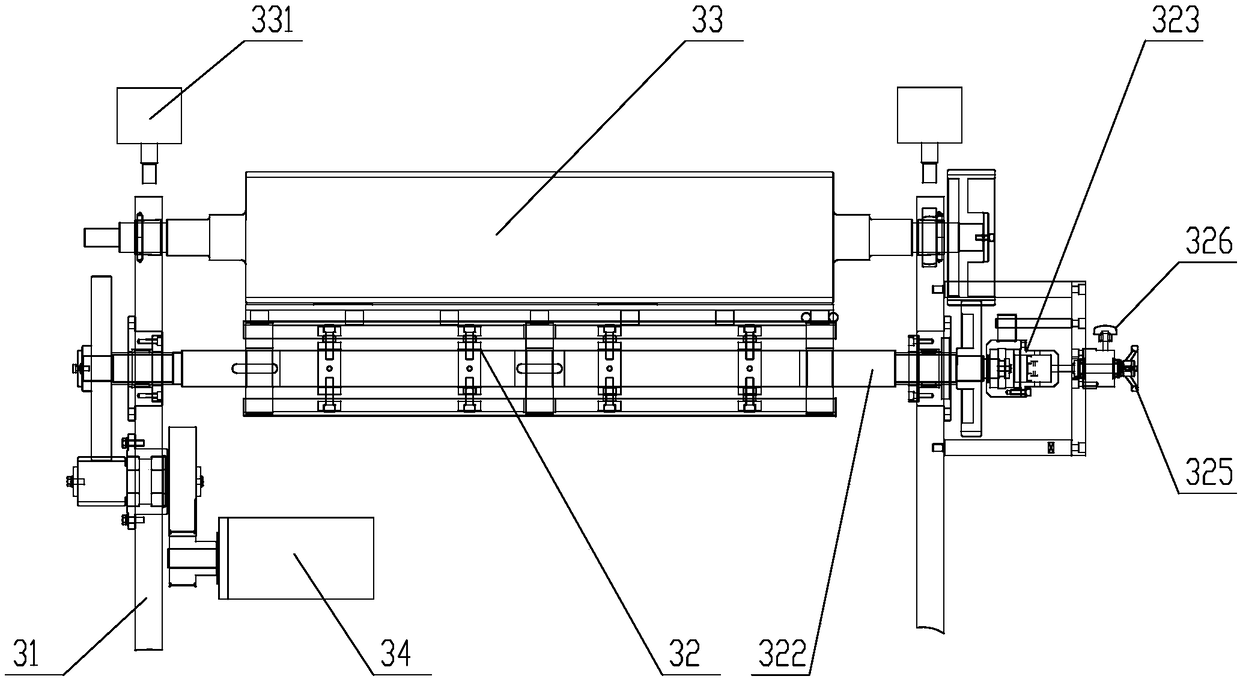

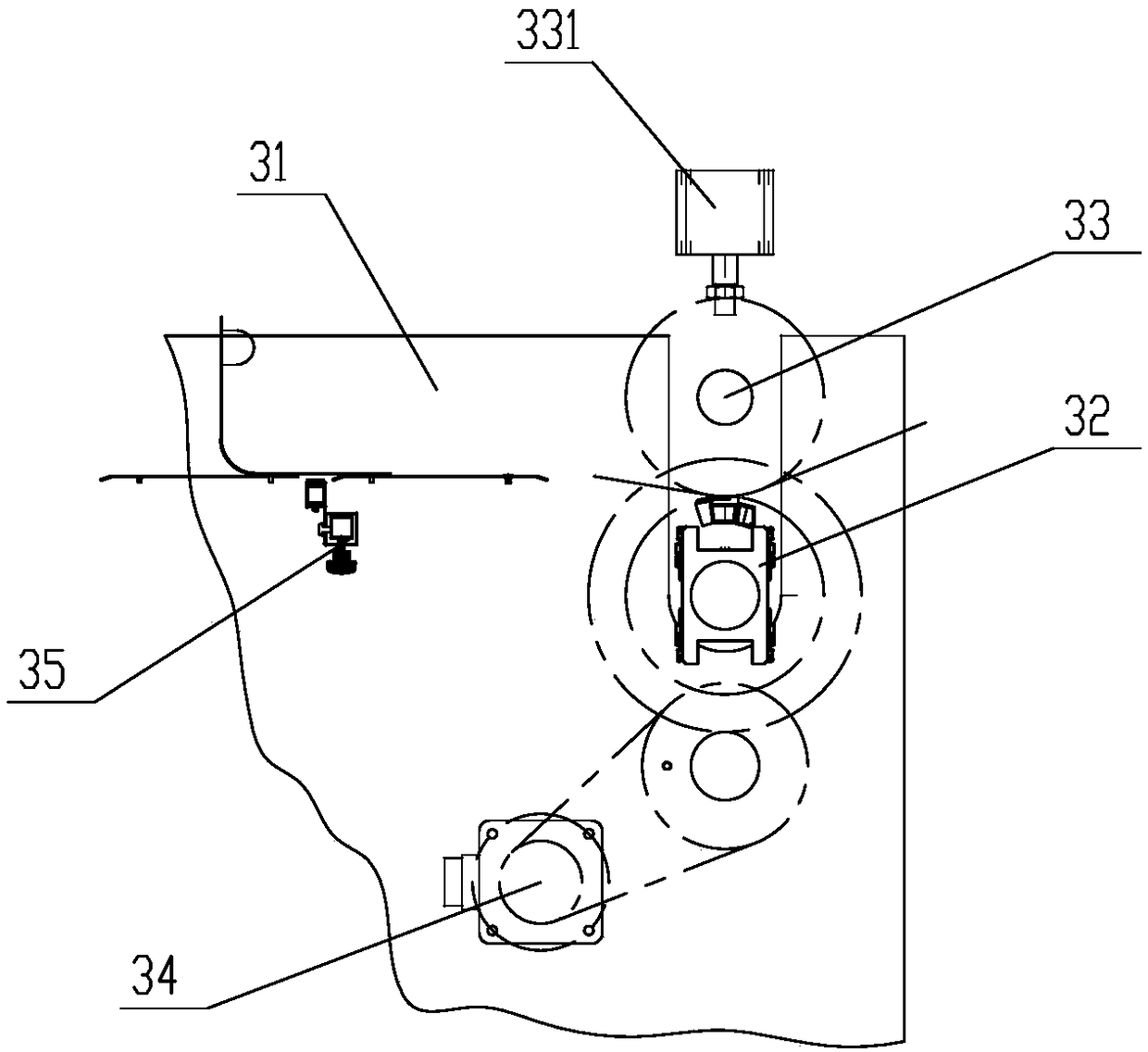

[0056] Such as Figure 2 to Figure 5 As shown, the cutting machine includes a cutting machine body 31, a cutter shaft assembly 32 and a back roller 33, the cutter shaft assembly 32 and the back roller 33 are installed on the cutting machine body 31, and both are parallel to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com