License plate frame support

A license frame and camera technology, applied in the field of auto parts, can solve the problems of camera damage and shorten the service life of the camera, and achieve the effect of reducing wear and improving the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

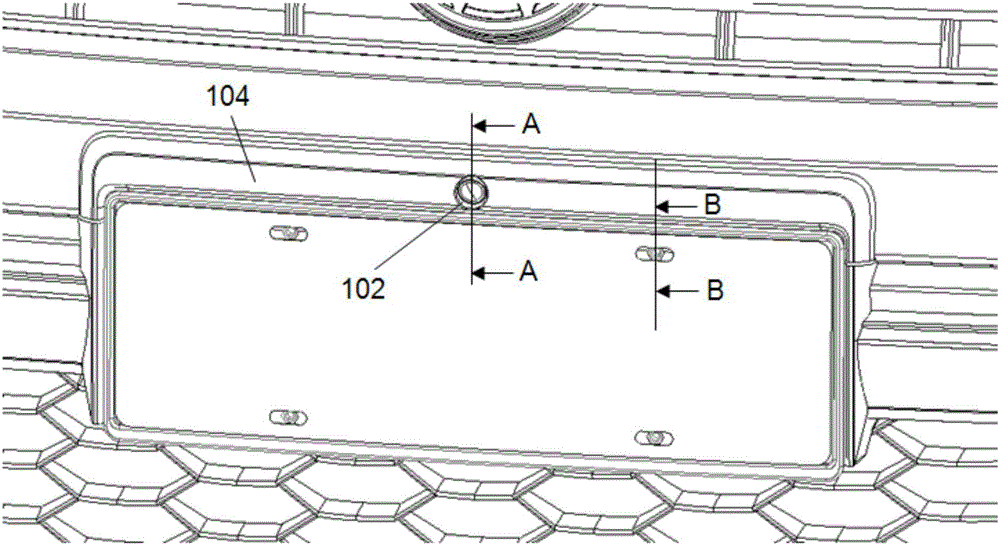

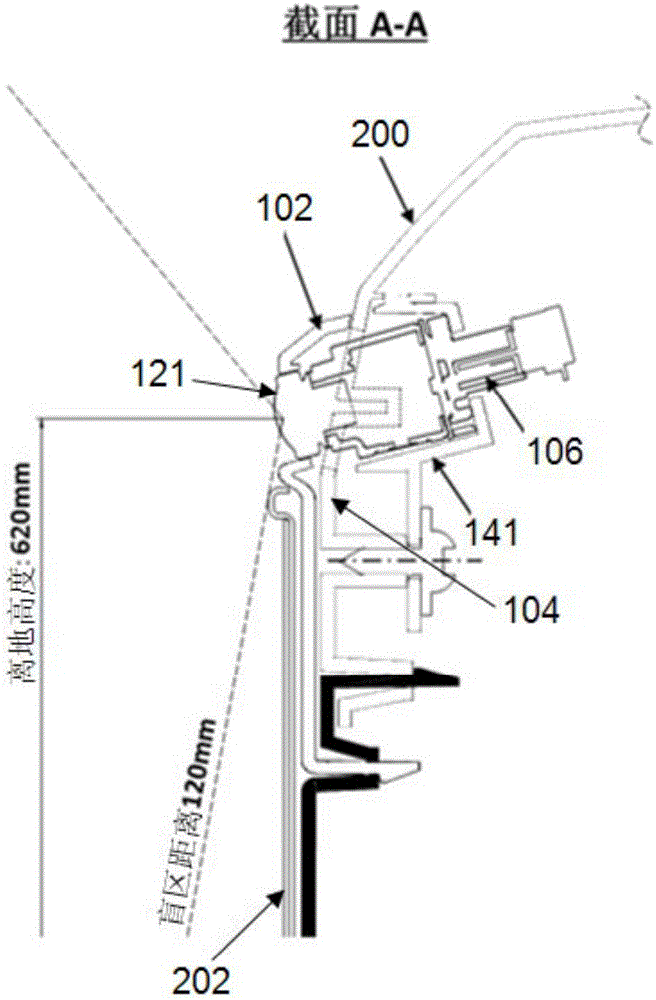

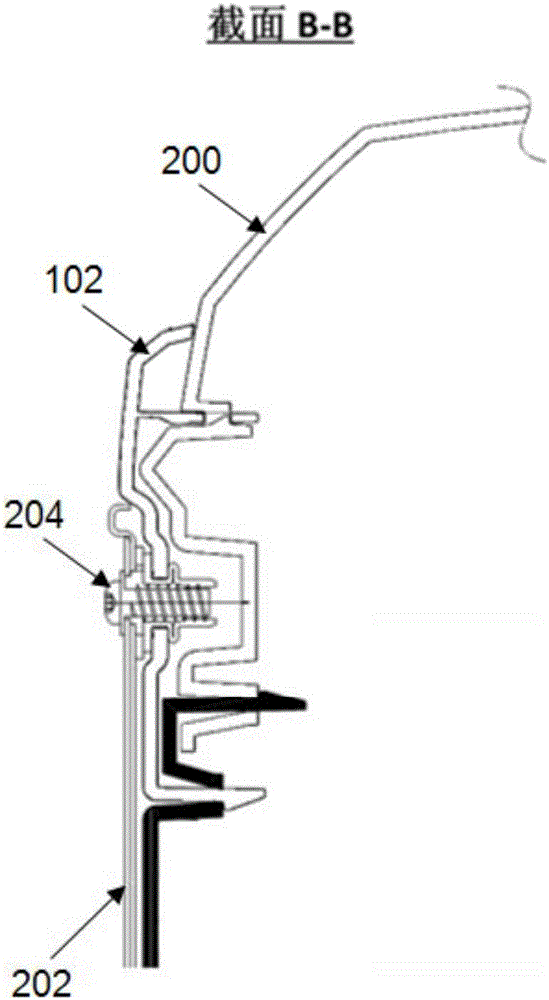

[0018] It is found through experiments that the height of the front camera of the car from the ground is too small, which will significantly affect the damage of the camera. Generally, the front camera is usually arranged on the lower grille. This solution has the advantages of good concealment, small blind area of vision, and unified bumper body. However, there are also the following shortcomings that need to be resolved urgently:

[0019] 1) Because the position of the grille area is low and the airflow speed is fast, the lens surface of the camera is easily damaged by the stones brought by the vehicle in front.

[0020] 2) It has a certain adverse effect on the heat dissipation of the engine.

[0021] 3) Due to the low loading rate of the camera, there are too many variants of the lower grille (usually need to distinguish between high and low), and the investment cost of the mold is high.

[0022] In the case of the same use environment and use time, the height of the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height above ground | aaaaa | aaaaa |

| Height above ground | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com