A kind of standardized cold box system and cold chain transportation method for cold chain transportation

A technology of cold chain transportation and cold box, which is applied to the transportation of passenger cars, transportation and packaging, railway car body parts, etc., and can solve the problems of inability to ensure the integrity of the goods, unreasonable use of refrigerated car space, and reduced transportation and distribution efficiency. Achieve the effect of avoiding unpacking and sorting, avoiding economic losses, and improving transportation quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

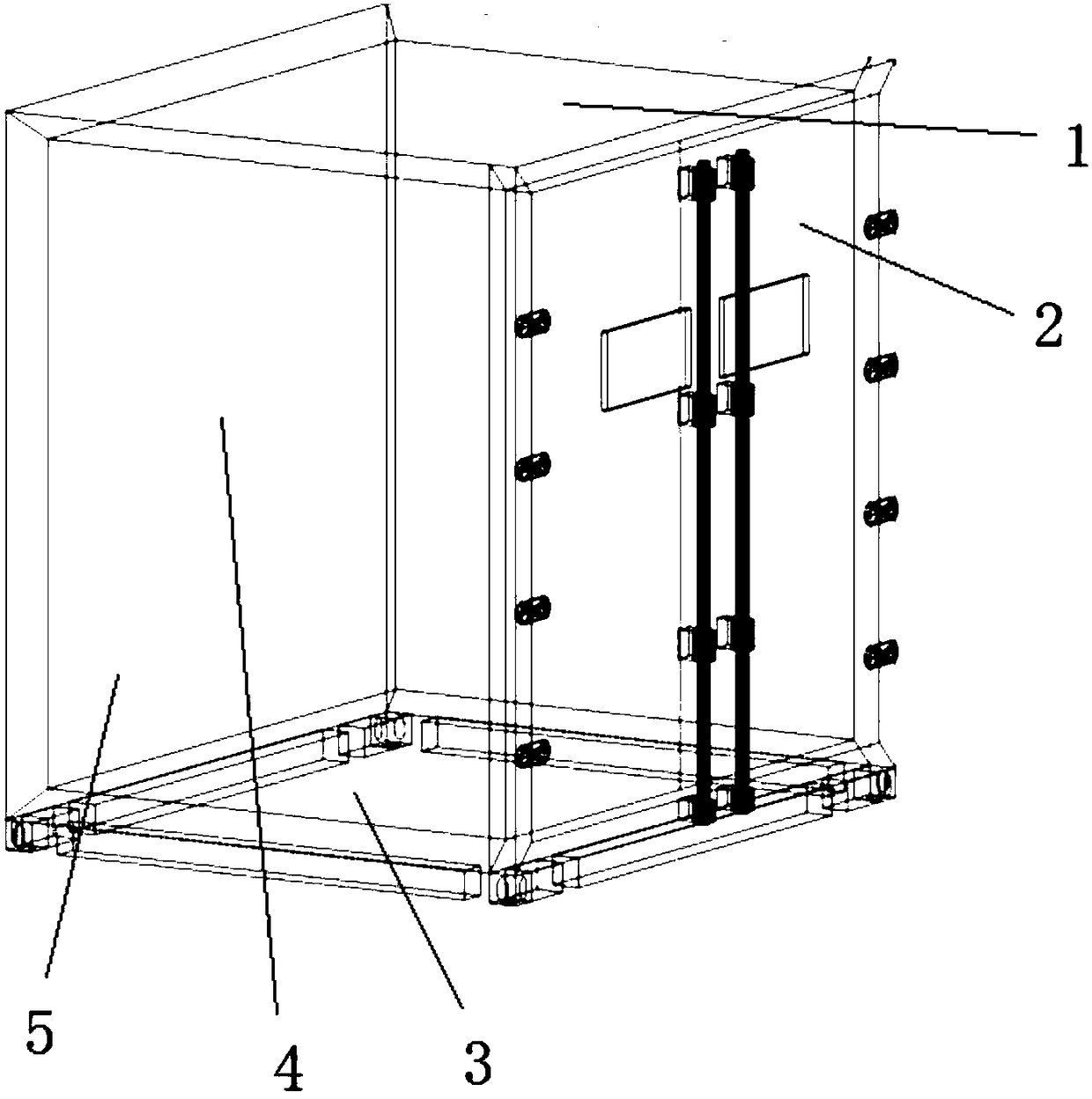

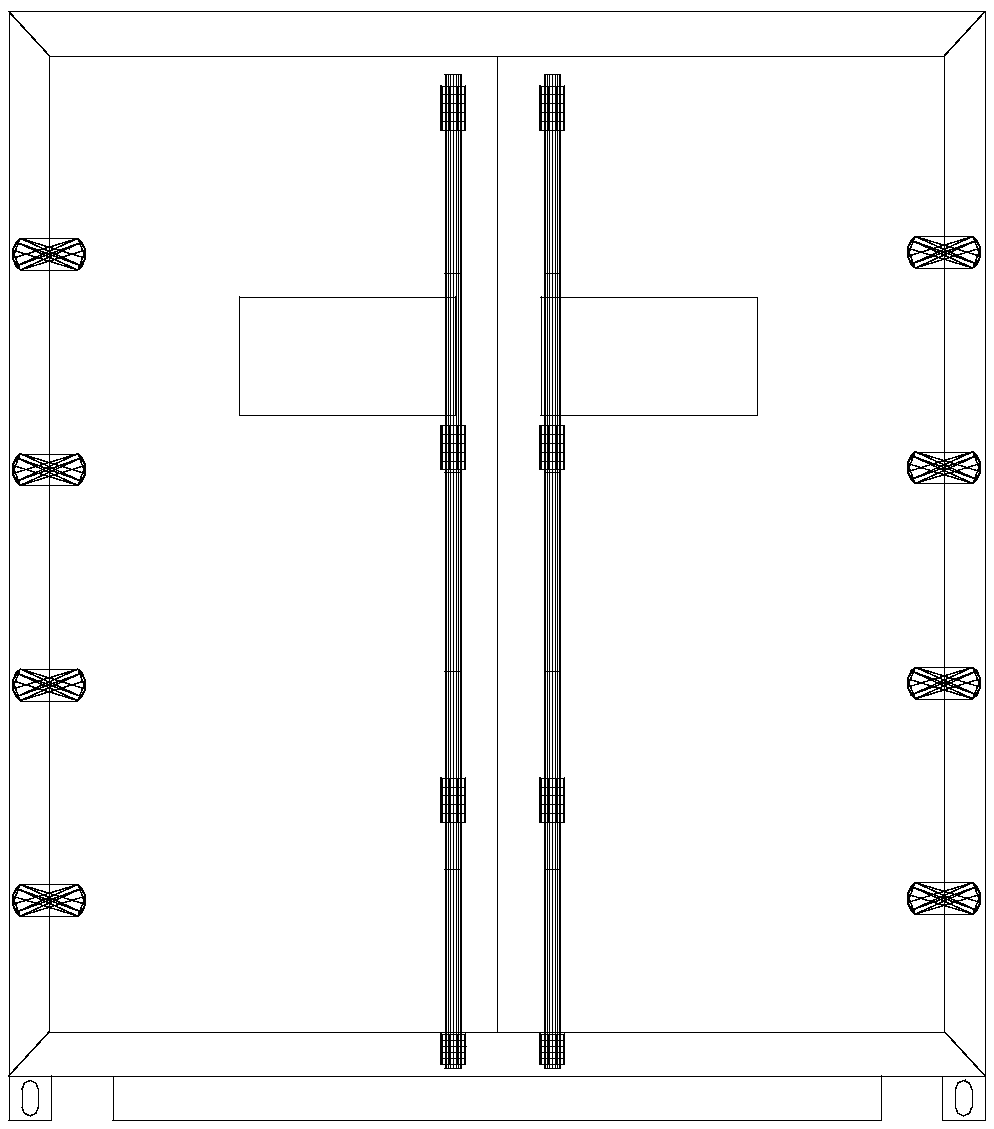

[0055] To achieve the above object, the utility model adopts the following technical solutions:

[0056] Standardized cold box system design

[0057] (1) Size design

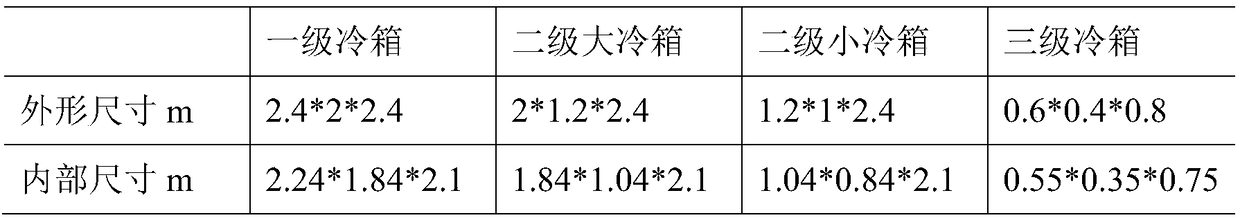

[0058] Standard cold boxes of different sizes need to meet the stowage requirements of different vehicles and the assembly requirements of cold boxes of different sizes. Therefore, by calculating the specific size of the cold box as shown in Table 1

[0059] Table 1 Standard cold box size

[0060]

[0061] There is a multiple relationship between the sizes of the four cold boxes, and suitable assembly can be performed, for example, two or four secondary cold boxes can be assembled into a first-level cold box. The first-level cold box is mainly used for trunk line transportation, and can also be used for branch line transportation and distribution to large customers; the second-level cold box is mainly used for branch line transportation and terminal distribution for small and medium customers, and can also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com