Waste compression device

A technology of garbage compression and garbage, applied in the direction of garbage conveying, garbage collection, storage devices, etc., can solve the problems of reducing the garbage carrying space, small garbage carrying capacity of the box, and low garbage compression efficiency, so as to expand the carrying space and compress the garbage. , the effect of reducing the number of round trips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

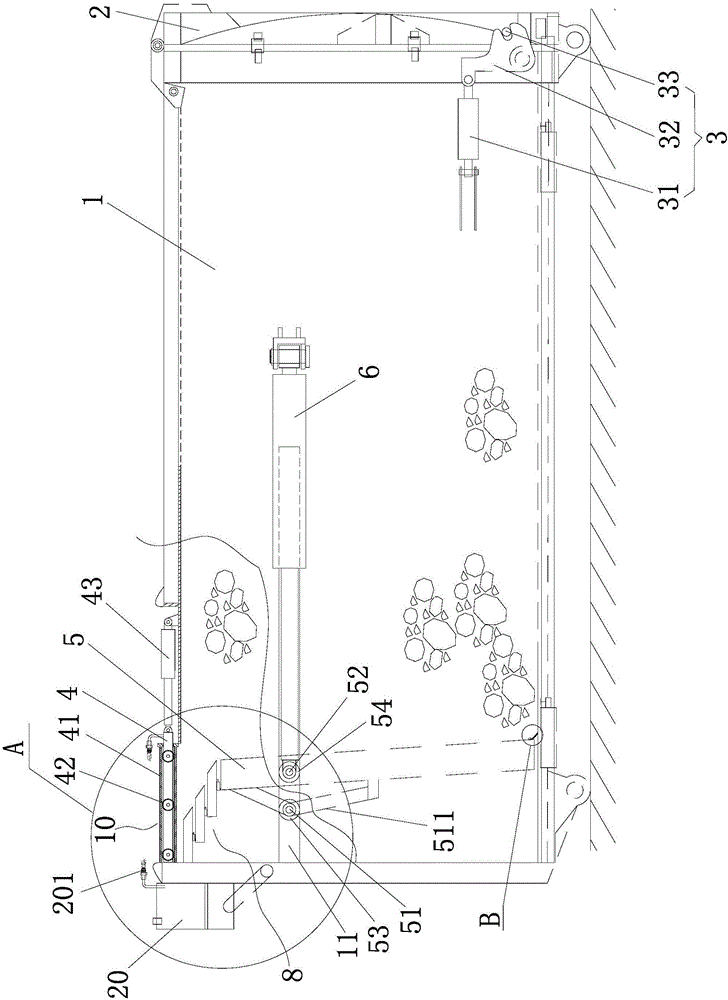

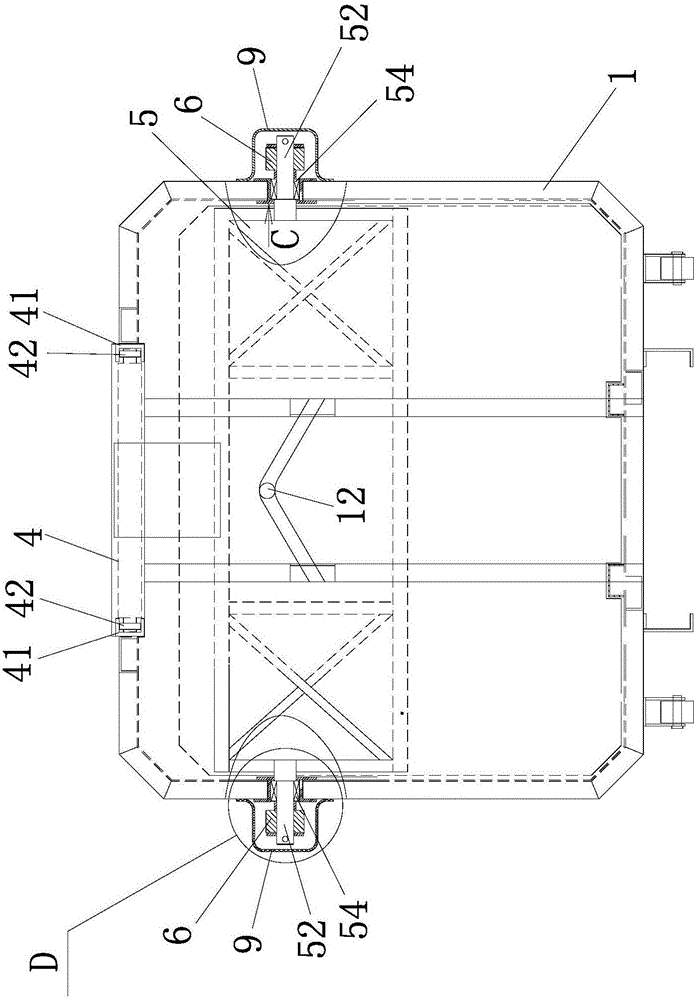

[0032] Embodiment one, Figure 1 to Figure 7 As shown, a garbage compression device includes a box body 1, a rear door 2 is hinged at the rear of the box body 1, and a locking mechanism 3 is provided between the box body 1 and the back door 2, and the locking mechanism 3 includes a locking oil cylinder 31. The hook arm 32 and the hanging pin 33, the middle part of the hook arm 32 is hinged at the lower part of the rear side of the box body 1, the hanging pin 33 is fixed at the lower part of the side of the rear door 2, and one end of the locking cylinder 31 is hinged with one end of the hook arm 32 , the other end of the locking oil cylinder 31 is hinged on the side of the box body 1 , and the other end of the hook arm 32 is provided with a hook groove to cooperate with the hanger pin 33 .

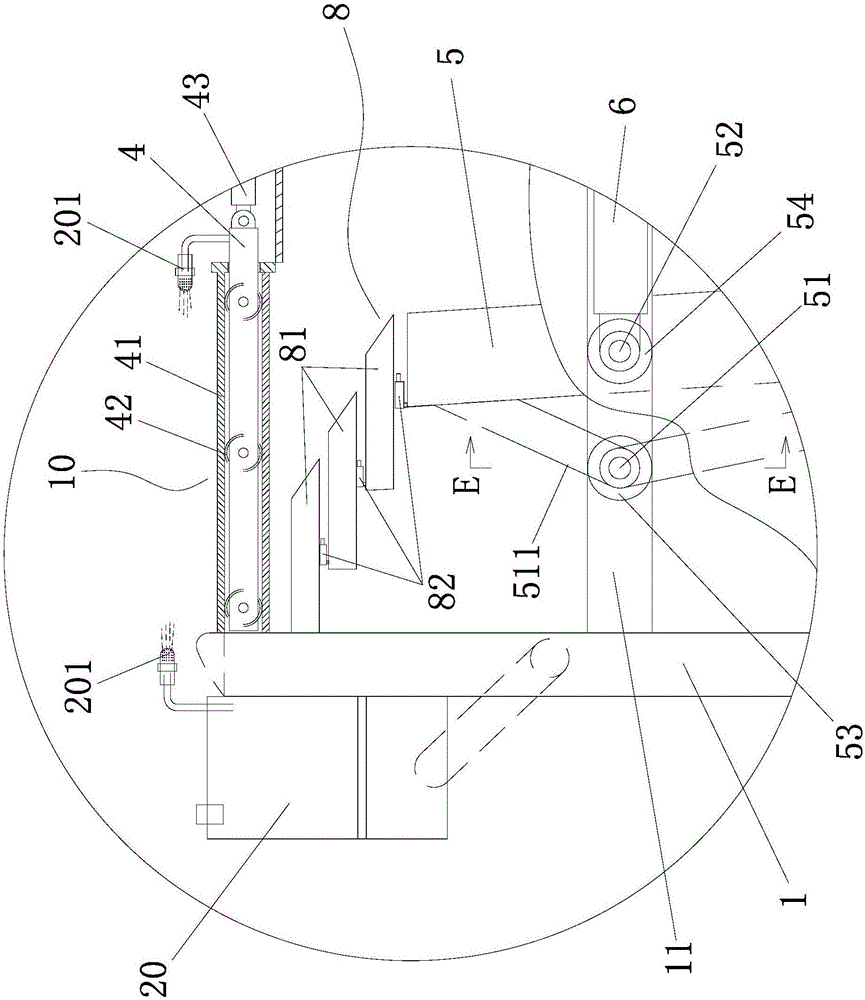

[0033]The front side of the box body 1 top is provided with a garbage feeding port 10, and the garbage feeding port 10 is provided with an openable top cover 4, a push plate 5 is housed in...

Embodiment 2

[0045] Embodiment two, Figure 12 As shown, it differs from Embodiment 1 in that when two push-pull oil cylinders 6 are installed on the two outer sides of the box body 1, two push-pull oil cylinders 6 are provided on the two outer sides of the box body 1 corresponding to the two push-pull oil cylinders 6. The elongated transverse through hole 11, two second connecting pins 52 are fixedly connected to both sides of the push plate 5, and each second connecting pin 52 passes through an elongated transverse through hole 11 and one end of a push-pull oil cylinder 6 Hinged, the other end of each push-pull cylinder 6 is hinged on the outer surface of the box body 1, the middle part of each second connecting pin 52 is covered with a second roller 54, and the second roller 54 moves along the inner wall of the long strip-shaped transverse through hole 11 . At this time, both sides of the push plate 5 do not need to be fixedly connected to the first connecting pin 52 as described in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com