Compression roller device capable of enabling pipe belt conveyor to be adjusted into circle

A conveyor and round tube belt type technology, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problem that the pressure roller structure cannot be well realized, and achieve good tube forming effect, enhanced bearing capacity, Easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in detail as follows by specific embodiment

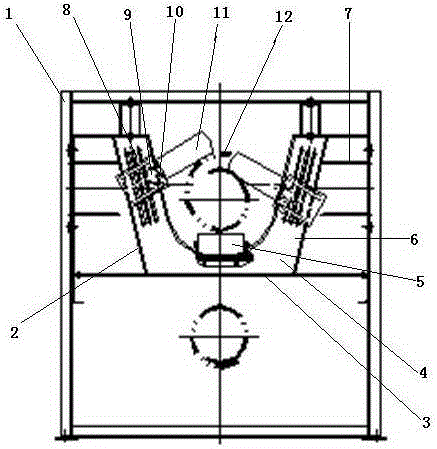

[0018] exist figure 1 Among them, the circular tube belt conveyor can be adjusted into a circular pressure roller device, including: a pressure roller support part 1 and a pressure roller part 2 installed on the transition frame of the circular tube belt conveyor. The cross section of the pressure roller support of the transition frame is Rectangular structure, connected by section steel, the upper part is the heavy-duty operation area, the lower part is the light-load operation area, there is a partition 3 in the middle, and the pressure roller seat 4 is installed on the partition 3, and the pressure roller seat 4 is a U-shaped structure , the bottom of the pressure roller seat 4 is equipped with a horizontal pressure roller 5, the two sides of the pressure roller seat 4 are oblique columns 6, the outside of the oblique column 6 has a lateral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com