Vertical lifting conveyor

A vertical lifting and conveyor technology, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problem that the belt of the hoist is easy to deviate, the replacement of wearing parts of the belt is troublesome, and the lifting block is easy to be degummed and loosened, etc. problem, to achieve the effect of not easy to deviate, low cost and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

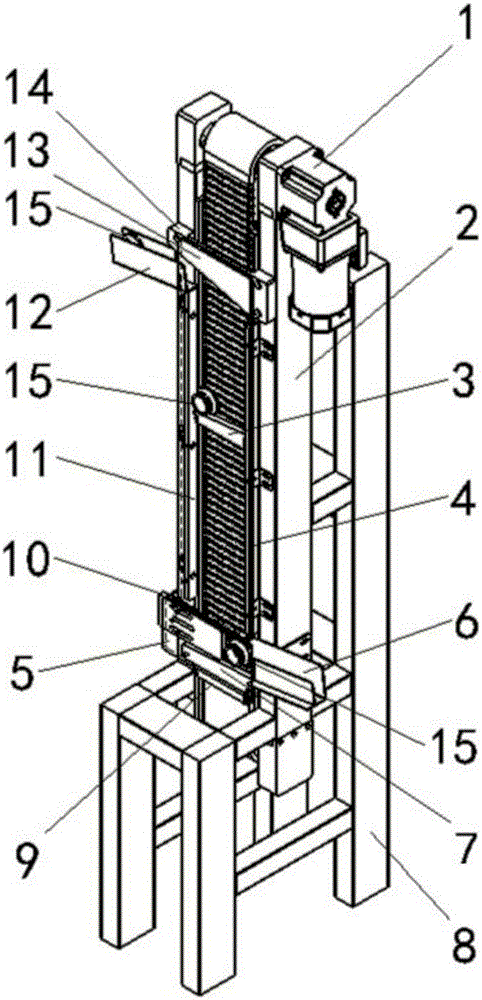

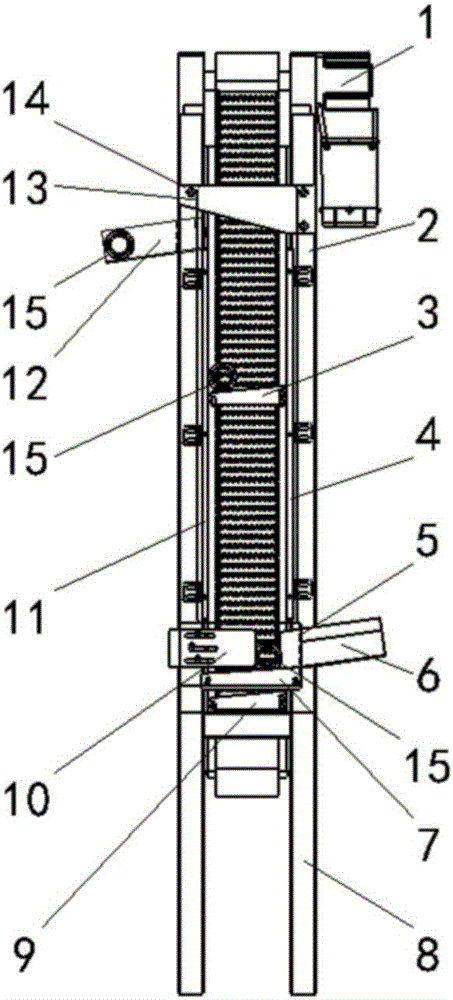

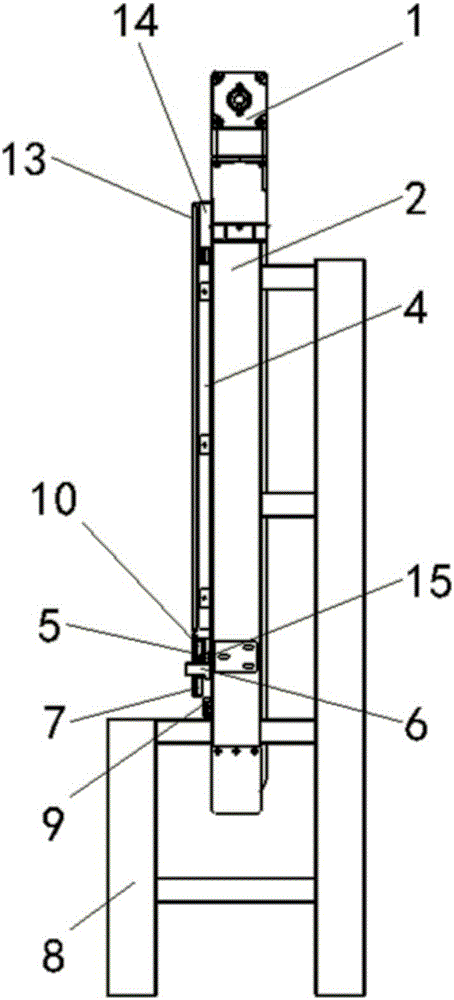

[0024] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as Figure 1 to Figure 4 As shown, the vertical lifting conveyor of the present invention includes a motor 1, a chain plate conveyor unit 2, a lifting block unit 2 3, a right baffle plate 4, an outer baffle plate 5 for feeding suspension, and a feeding channel 6, and a lower feeding suspension Support plate 7, bracket unit 8, lifting block unit 1 9, feeding suspension adjustment plate 10, left baffle plate 11, discharge channel 12, lifting outer baffle plate 13, lifting blocking plate 14, lifting block 16, upper connecting circular shaft 17, the right mounting block 18, the following connecting circular shaft 19, the lower chain plate joint 20, the left mounting block 21, and the upper chain plate joint 22. The workpiece 15 is not a component of the present invention, but only a symbol for description. For clear and simple expres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com