Semi-automatic elevator platform

A semi-automatic, lifting platform technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems that the lifting device cannot carry heavy objects, the range of lifting is small, and the operation is inconvenient, so as to save labor time, easy operation and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

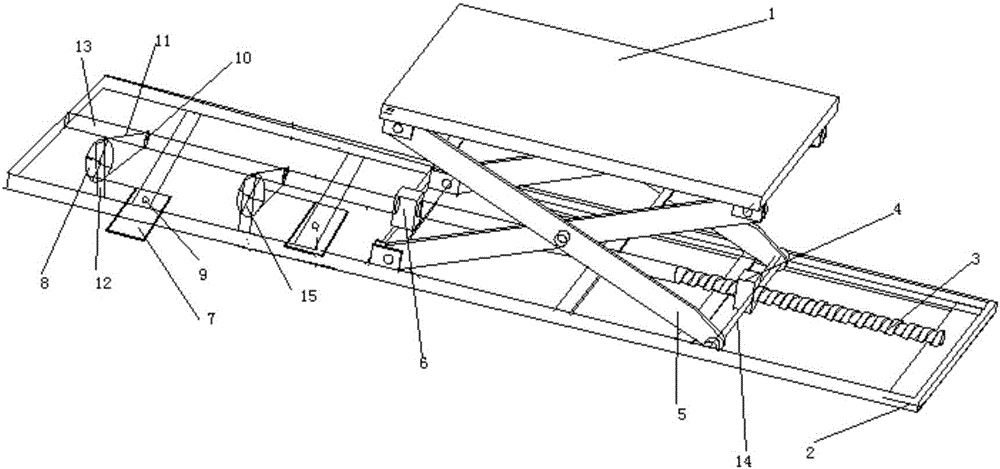

[0020] Please refer to figure 1 , a semi-automatic lifting platform, including a platform 1, a base 2 and a screw 3, the platform 1 and the base 2 are twisted together through a pair of X-shaped cross arms, and the X-shaped cross arms include a pair of support bars 5, and a pair of The middle part of the support bar 5 is fixed by a group of nuts and bolts, and one side of the lower end of the X-shaped cross arm is hinged on the slide bar 14 located on the inside of the base, and the slide bar 14 can slide freely on the inside of the base 2; One end is provided with a stud 13, and the stud 13 passes through the support block 6 fixed on the base 2, and the screw 3 passes through the nut block 4 fixed on the slide bar 14 that matches the screw 3; the length of the screw 3 is not less than The length of the platform 1; this is conducive to the smooth transmission of the lifting platform.

[0021] One end on the base 2 is also provided with two groups of lifting mechanisms. The li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com