Automatic defoaming device for fermentation tank

A technology of defoaming device and fermenter, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical cleaning device, etc., can solve the problem of reducing the growth and reproduction speed of bacteria, affecting bacteria and Oxygen contact area, increased bacterial infection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

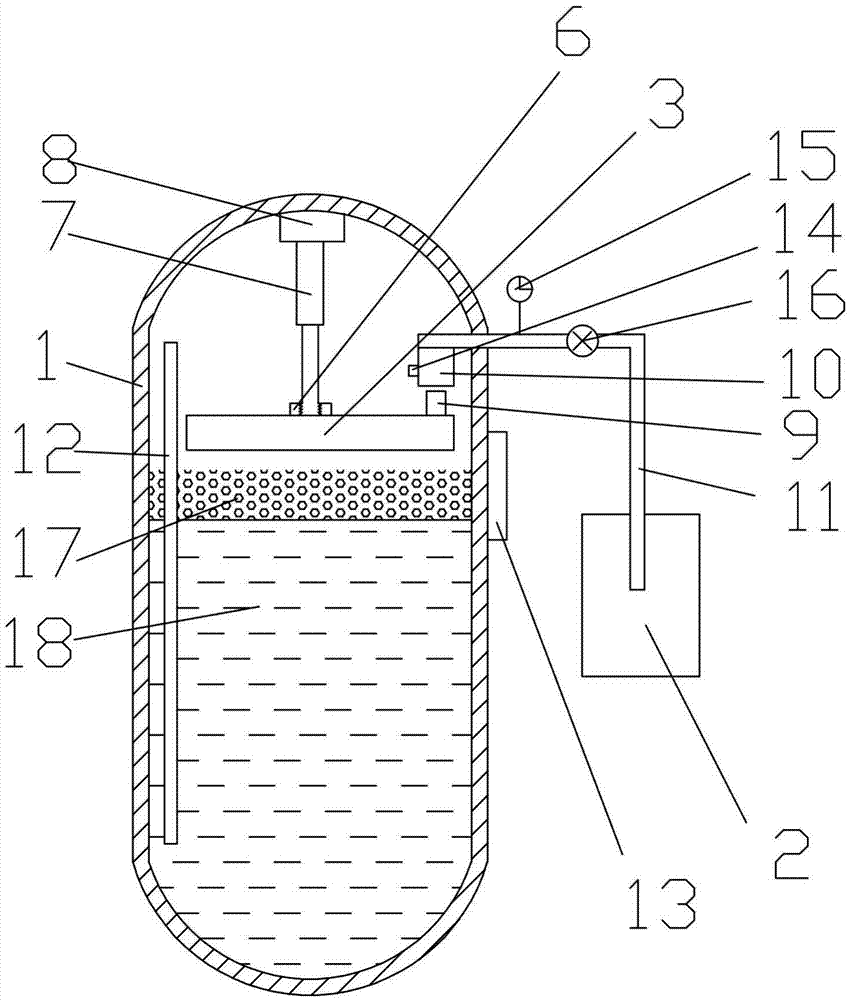

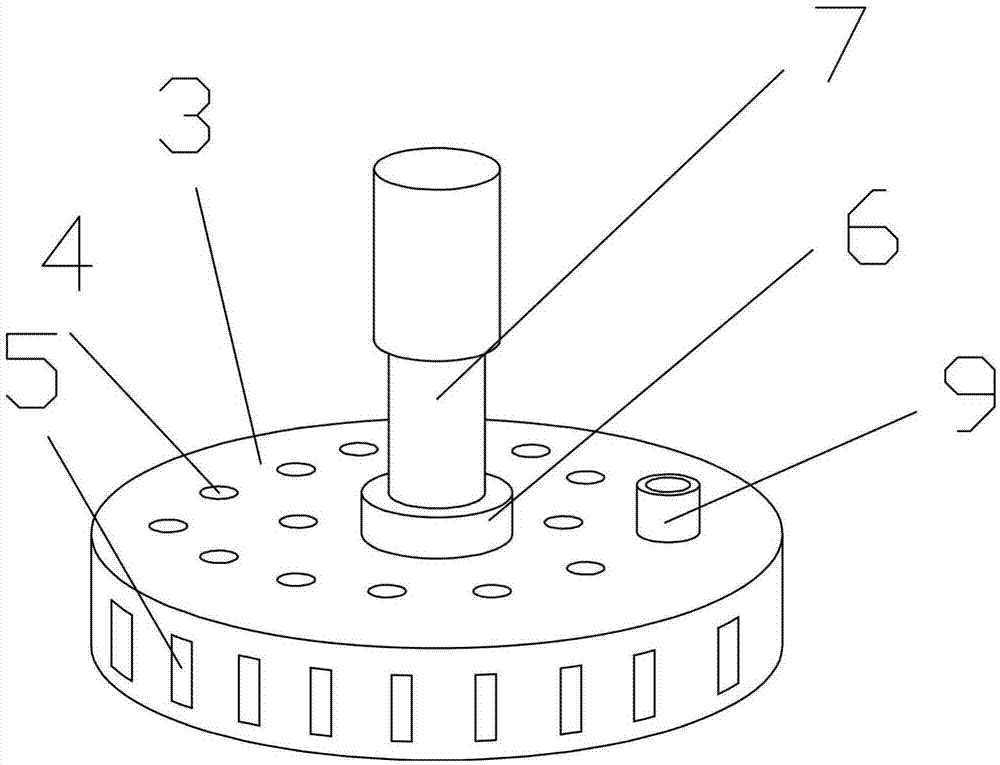

[0018] Combine below Figure 1-2 The present invention is further described:

[0019] An automatic defoaming device for a fermentation tank, which mainly includes a fermentation tank body 1, a foam collection device, a foam discharge device and a foam storage device 2. The foam collection device includes a foam collector 3, a telescopic rod 7 and a telescopic controller 8. The foam collector 3 is provided with an opening and closing hole 4 and a side opening and closing hole 5. The foam is collected by switching the opening and closing of the opening and closing hole 4 and the side opening and closing hole 5. The foam collector 3 is connected to the telescopic rod 7 through the threaded connection block 6, which is convenient Removed, the telescopic rod 7 is connected to the telescopic controller 8, and the telescopic controller 8 controls the telescopic rod 7 to extend and retract, so as to control the rise and fall of the foam collector 3, the telescopic controller 8 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com