Stabilization method of diatomite/nanometer TiO2 photocatalytic paint additive

A technology of diatomite and photocatalysis, applied in the direction of coating, etc., can solve the problem of low photocatalytic efficiency of photocatalytic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

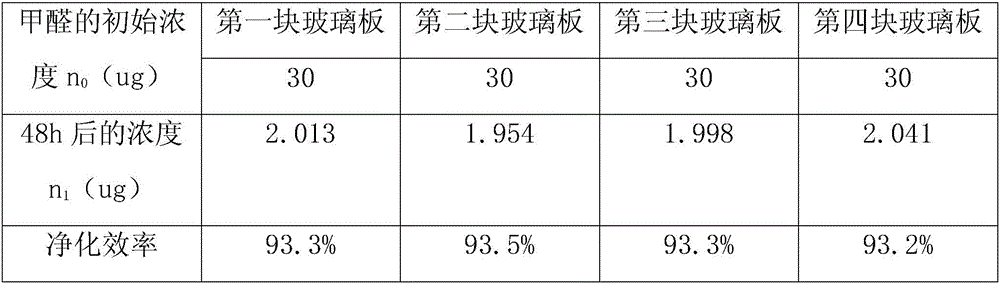

Examples

Embodiment 1

[0031] Diatomaceous earth / nano TiO 2 Stabilization method of photocatalytic coating additives, using diatomite, tetrabutyl titanate and styrene as raw materials, using in-situ polymerization to synthesize polystyrene-protected diatomite / nano-TiO 2 Composite materials, including the following steps:

[0032] (1) Add 10g of diatomaceous earth to a 250ml three-necked flask, slowly add 100ml of ethanol, 10ml of tetrabutyl titanate and stir at a speed of 450r / min for 30min in a constant temperature water bath at 25°C to make diatomite and tetrabutyl titanate The solution is mixed evenly;

[0033] (2) Heat up to 55° C. and stir the mixed solution at a speed of 500 r / min until the ethanol is completely volatilized, then add water, and heat until the water is completely volatilized to obtain a dry solid;

[0034] (3) Wash the dried solid several times, dry it in vacuum at 50°C for 12h, and then calcinate it at 450°C for 5h to obtain diatomite / nano-TiO 2 composite materials;

[003...

Embodiment 2

[0038] Diatomaceous earth / nano TiO 2 Stabilization method of photocatalytic coating additives, using diatomite, tetrabutyl titanate and styrene as raw materials, using in-situ polymerization to synthesize polystyrene-protected diatomite / nano-TiO 2 Composite materials, including the following steps:

[0039] (1) Add 6g of diatomaceous earth to a 250ml three-necked flask, slowly add 80ml of ethanol and 15ml of tetrabutyl titanate, and stir for 35min at a speed of 550r / min in a constant temperature water bath at 35°C to make diatomite and tetrabutyl titanate The solution is mixed evenly;

[0040] (2) Heat up to 60°C and stir the mixed solution at a speed of 600r / min until the ethanol is completely volatilized, then add water, and heat until the water is completely volatilized to obtain a dry solid;

[0041] (3) Wash the dried solid several times, dry it in vacuum at 60°C for 8h, and then calcinate it at 500°C for 4h to obtain diatomite / nano-TiO 2 composite materials;

[0042]...

Embodiment 3

[0044] Diatomaceous earth / nano TiO 2 Stabilization method of photocatalytic coating additives, using diatomite, tetrabutyl titanate and styrene as raw materials, using in-situ polymerization to synthesize polystyrene-protected diatomite / nano-TiO 2 Composite materials, including the following steps:

[0045] (1) Add 12g of diatomaceous earth to a 250ml three-necked flask, slowly add 120ml of ethanol, 25ml of tetrabutyl titanate and stir at a speed of 500r / min for 36min in a constant temperature water bath at 40°C to make diatomite and tetrabutyl titanate The solution is mixed evenly;

[0046] (2) Heat up to 65° C. and stir the mixed solution at a speed of 500 r / min until the ethanol is completely volatilized, then add water, and heat until the water is completely volatilized to obtain a dry solid;

[0047] (3) Wash the dried solid several times, dry it in vacuum at 65°C for 9h, and then calcinate it at 550°C for 3.8h to obtain diatomite / nano-TiO 2 composite materials;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com