Silver nanoparticles and preparation method thereof capable of realizing controllable macroscopic quantity

A silver nanoparticle and macro-quantity technology, which is applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve problems such as difficulty in meeting large-scale macro-production, limited adsorption and reduction, and low content of nano-silver particles. Achieve the effects of uniform and controllable size, good dispersion and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

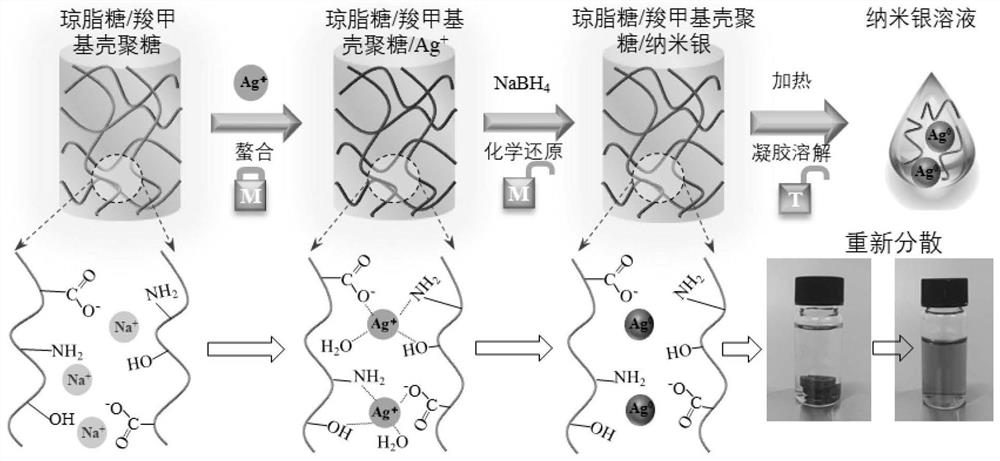

[0033] The invention provides a method for preparing silver nanoparticles in a macroscopically controlled manner, comprising the following steps:

[0034] S1. Add agarose and carboxymethyl chitosan into the lye, heat and stir to make them fully dissolve, and obtain a hot mixed solution; after the mixed solution is cooled, agarose / carboxymethyl chitosan composite gel is obtained. glue;

[0035] S2, fully soaking the composite gel obtained in step S1 in a solution containing silver ions to obtain a silver ion cross-linked double network composite gel;

[0036] S3, placing the silver ion cross-linked double network composite gel obtained in step S2 in a sodium borohydride solution for reduction reaction, to obtain a composite gel loaded with silver nanoparticles;

[0037]S4, the composite gel loaded with silver nanoparticles obtained in heating step S3, after it is fully dissolved, agarose / carboxymethyl chitosan / silver nanoparticles mixed solution is obtained, and after centrifu...

Embodiment 1

[0049] This embodiment provides a macro-controllable preparation method of silver nanoparticles, the schematic diagram of the preparation process is as follows figure 1 As shown, it specifically includes the following steps:

[0050] S1. Add agarose and carboxymethyl chitosan with a degree of deacetylation of 85% to a sodium hydroxide solution with a pH of 10, heat and stir at 85°C for 10 minutes to fully dissolve the agarose and carboxymethyl chitosan , to obtain a hot mixed solution; the concentration of agarose in the mixed solution is 1w / v%, and the concentration of carboxymethyl chitosan is 0.5w / v%; after the mixed solution is cooled to room temperature, the agarose / carboxylate Methyl chitosan complex gel.

[0051] S2, the composite gel obtained in step S1 is placed in a silver nitrate solution with a concentration of 0.1mol / L and soaked for 120min, so that the silver ions are fully adsorbed by the composite gel, and chelated crosslinked to obtain silver ion crosslinked ...

Embodiment 2~3 and comparative example 1

[0059] Embodiments 2-3 respectively provide a preparation method of silver nanoparticles. Compared with Embodiment 1, the difference is that the concentration of carboxymethyl chitosan in the mixed solution in step S1 is changed. The concentrations of carboxymethyl chitosan in Example 2 and Example 3 were 1w / v% and 2w / v% respectively, and the rest of the steps and process parameters were consistent with those in Example 1, and will not be repeated here.

[0060] Comparative Example 1 provides a method for preparing silver nanoparticles. Compared with Example 1, the difference is that carboxymethyl chitosan is not added in its step S1, and the prepared gel is only agarose gel. The remaining steps and process parameters are consistent with those in Example 1, and will not be repeated here.

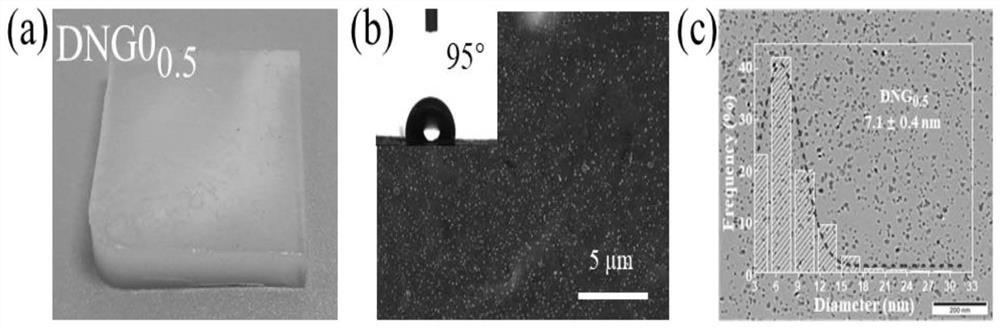

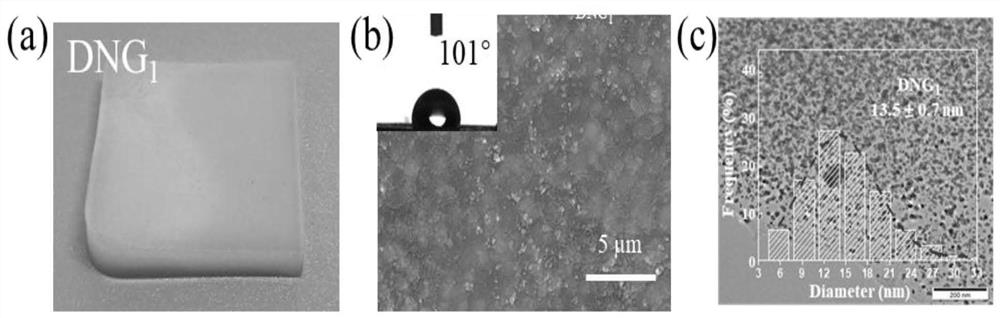

[0061] The performance tests of the gel and silver nanoparticles prepared in Examples 2 to 3 and Comparative Example 1 are as follows: Figure 3-5 Shown; The performance contrast between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com