A textile machine faucet frame

A textile machine and faucet technology, applied in the direction of looms, textiles, textiles and papermaking, etc., can solve the problems of fabric pollution, scratches on people and objects, sharp corners of channel steel, etc., to improve stability and life, and prevent foreign matter Entry, pollution prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

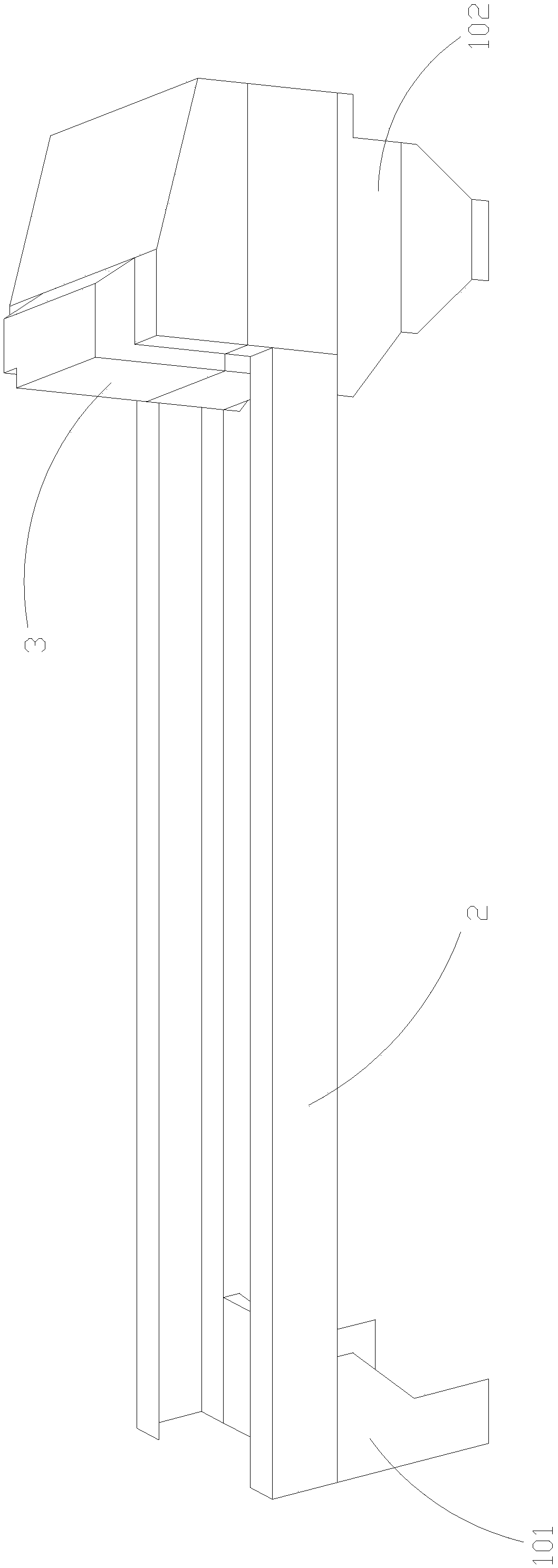

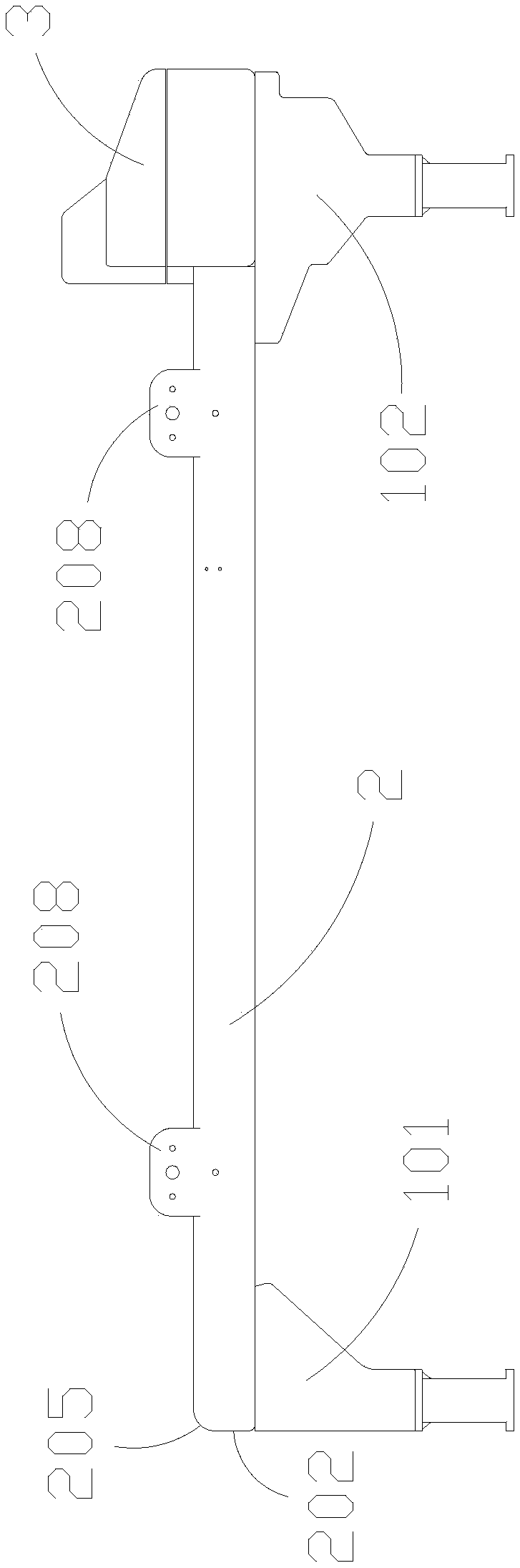

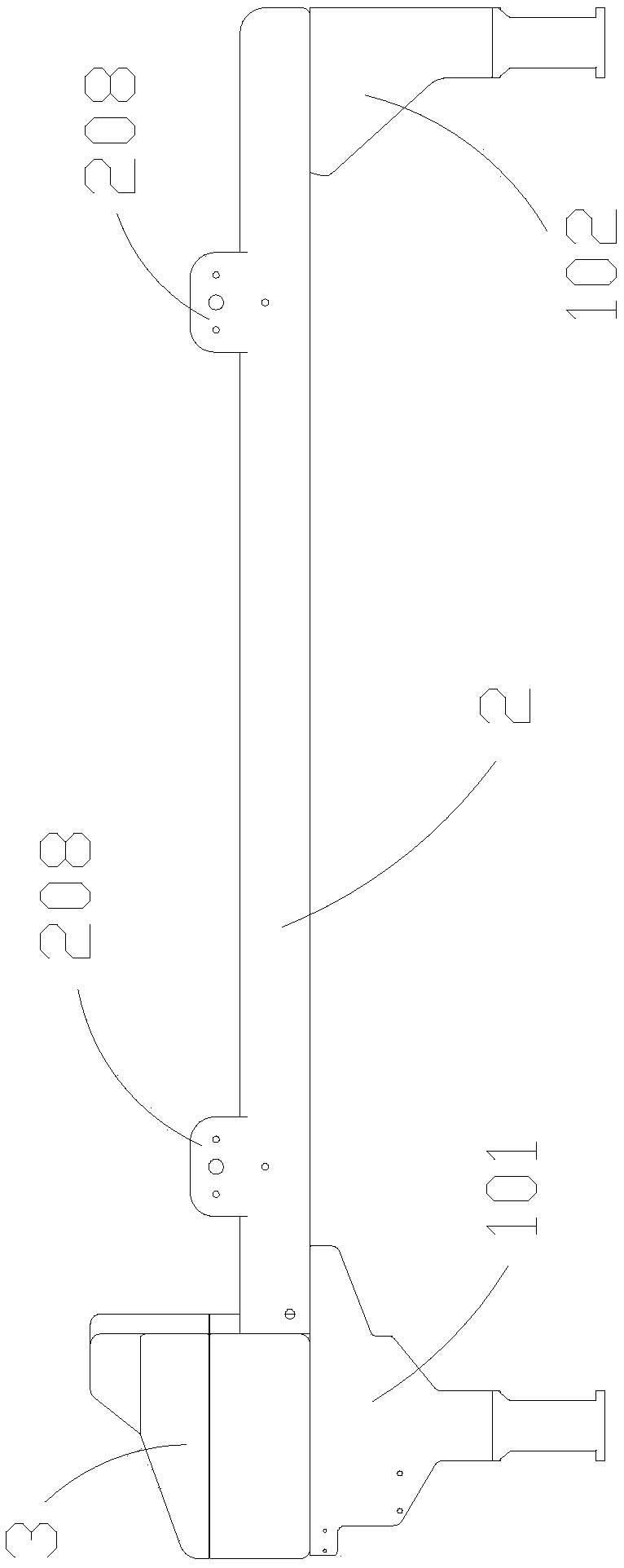

[0026] see Figure 2-7 , A textile machine faucet frame of the present invention includes a left bracket 101 , a right bracket 102 , a beam 2 and a transmission mechanism 3 .

[0027] The cross beam 2 is a metal bending beam, the first end of the metal bending beam is fixed on one of the left bracket 101 and the right bracket 102 in parallel with the transmission mechanism 3, and the second end of the metal bending beam is along the distance away from the transmission mechanism. The direction extension is fixed on the other of the left bracket 101 and the right bracket 102 . In this embodiment, the right end of the metal bending beam is preferably fixed on the right bracket 102 in parallel with the transmission mechanism 3 , and the other end of the metal bending beam is extended and fixed on the left bracket 101 along the direction away f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com