Control device and control method for follow-up operation of railway material transport vehicle and screen cleaning machine

A control device and screen cleaning machine technology, which is applied to electric controllers, controllers with specific characteristics, roads, etc., can solve the power loss of the screen cleaning machine, the inability of the material transport vehicle to respond in time, and the operating power of the screen cleaning machine Loss and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

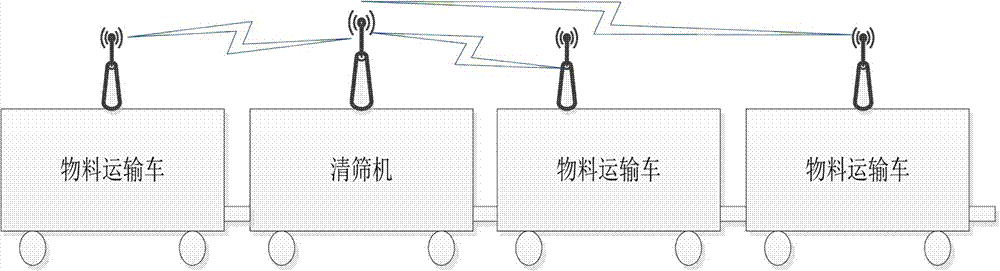

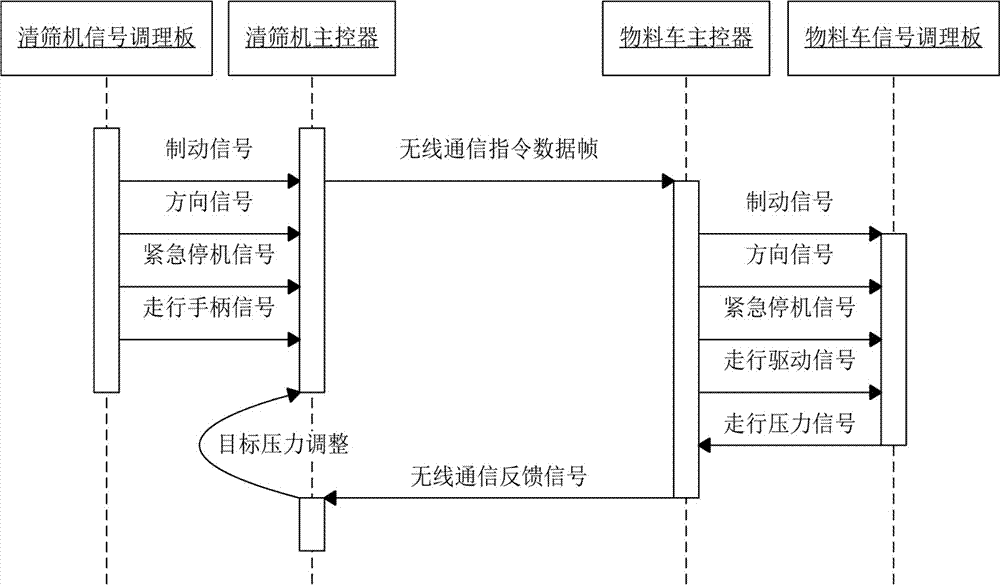

[0037] Embodiment 1: A control device and control method for a follow-up operation of a railway material transport vehicle and a sieve cleaner, the control device includes a follow-up controller for a sieve cleaner and a follow-up controller for a material transport vehicle, and the follow-up control for the sieve cleaner The device is installed on the cleaning machine, and the follow-up controller of the material transport vehicle is installed on the material transport vehicle. The follow-up controller of the screen cleaning machine is connected with the follow-up controller of the material transport vehicle through a wireless signal, wherein:

[0038] The follow-up controller of the sieve cleaning machine includes the main controller of the sieve cleaning machine, the signal conditioning board of the sieve cleaning machine and the wireless data transmission module of the sieve cleaning machine. The wireless data transmission module of the screen cleaning machine is integrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com