A multi-working condition movable traveling rail support device and its application method

A technology of supporting devices and running rails, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of increased workload, limited use range, pinch plate, bolt loss, etc., so as to reduce workload, improve installation and disassembly efficiency, Avoid Lost Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

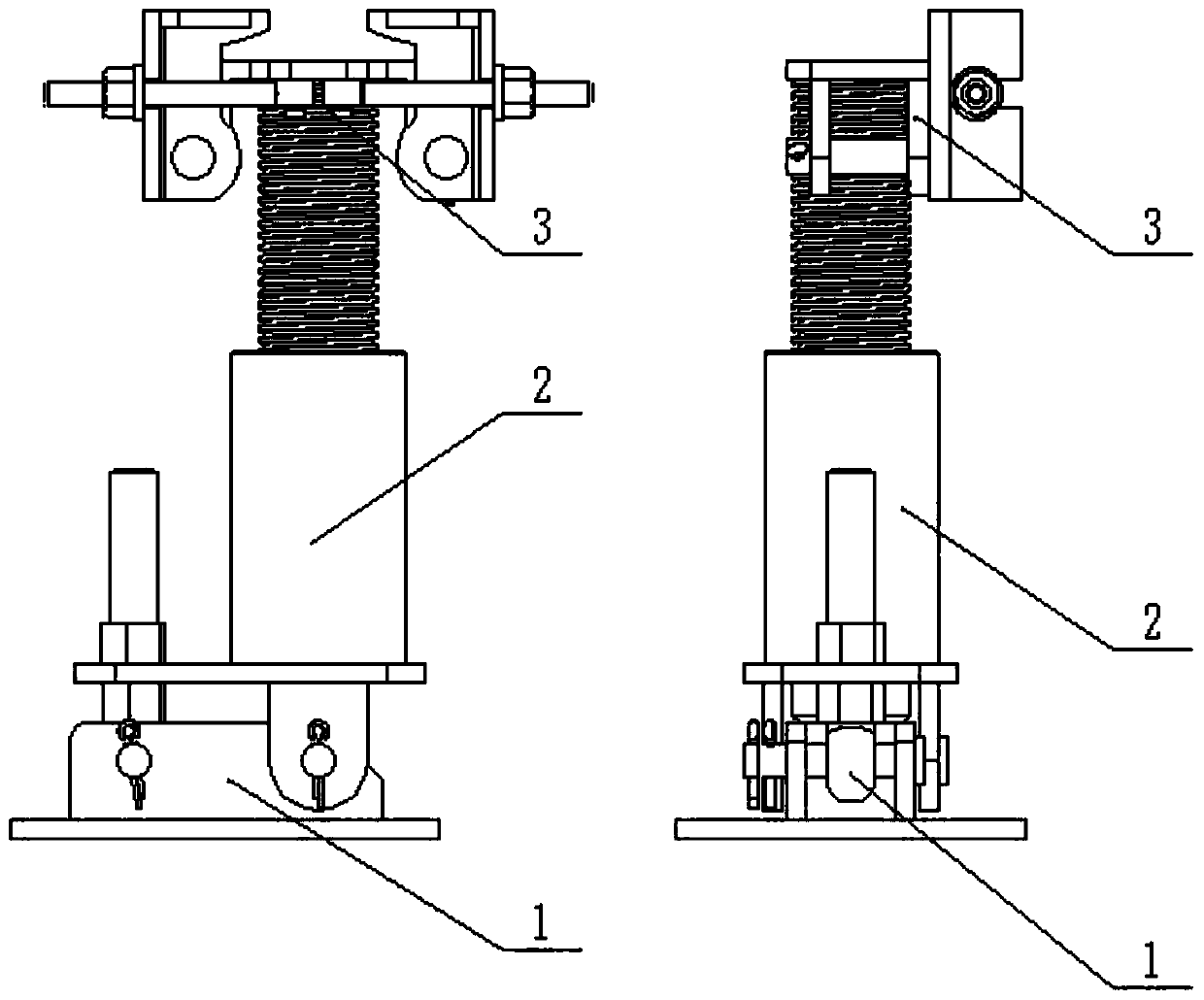

[0032] see figure 1 , the present invention is mainly made up of base 1, supporting leg 2 and bearing rail groove 3 three major parts.

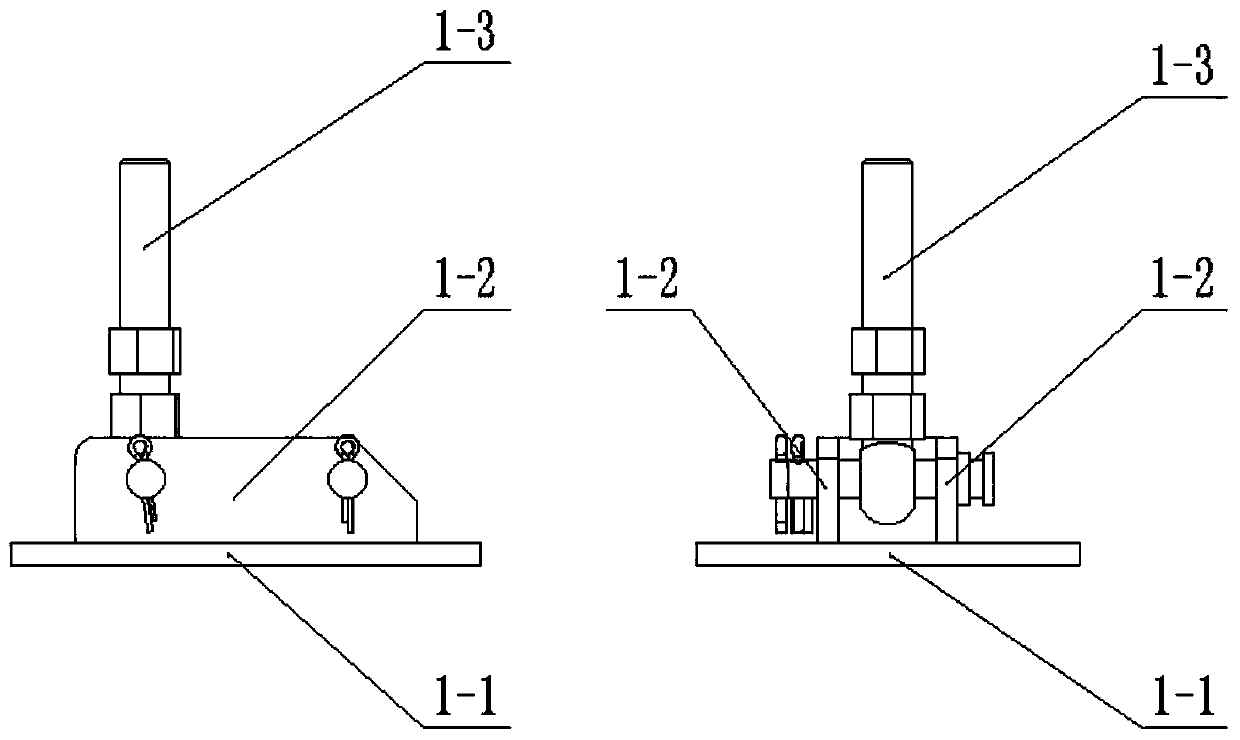

[0033] see figure 2 , Base 1 is made up of base plate 1-1, vertical plate 1-2 and first swing bolt 1-3. The base plate 1-1 is a shaped steel plate, and mounting holes are provided at the four corners for mounting and fixing on the base. The two vertical plates 1-2 are shaped steel plates, which are respectively welded on both sides of the base plate 1-1, and a pin hole is provided at the front and rear respectively, and the first joint bolt 1-3 passes through the pin shaft at the front of the vertical plate 1-2 Connect with it.

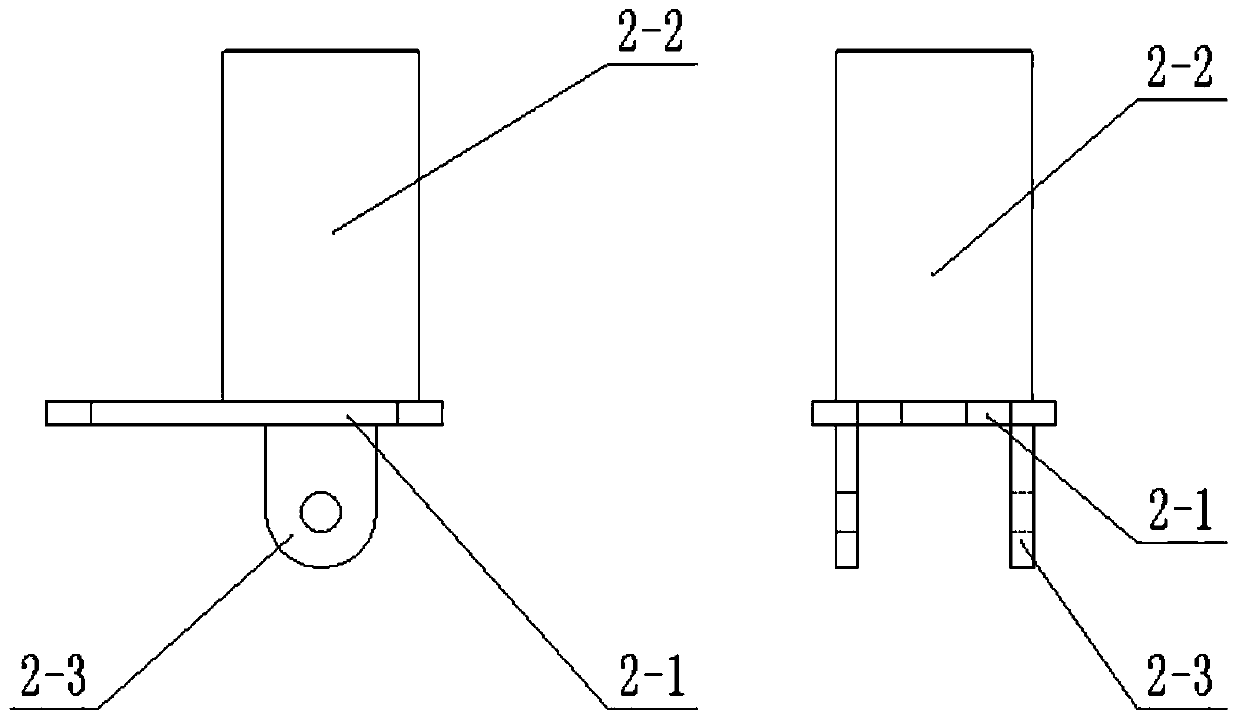

[0034] see image 3 , Leg 2 is made up of base plate 2-1, screw seat 2-2 and leg ear plate 2-3. The base plate 2-1 is a shaped steel plate, and the front portion is provided with a gap, and the swing bolt 1-3 can be snapped into it. The screw seat 2-2 is a circular steel pipe, which is provided with threads an...

Embodiment 2

[0037] The invention relates to a method for using a multi-working-condition movable traveling rail support device.

[0038] 1) According to the positions of the mounting holes at the four corners of the base plate 1-1, drill holes in the corresponding positions of the base, then install and fix the base 1 and the outrigger 2 on the base with expansion bolts, and snap the swing bolts 1-3 into the base plate 2-1 gap.

[0039] 2) Adjust the height of the nuts of the first swing bolts 1-3 so that the supporting leg 2 is in a vertical state.

[0040] 3) Rotate the lead screw 3-2 to the lead screw seat 2-2, install the bearing rail groove 3 on the leg 2, and rotate the lead screw 3-2 according to the laying height requirements of the running rail 4, so that the height of the bearing rail groove 3 Meet the needs.

[0041] 4) Open the clamping rail plates 3-3 on both sides, and place the running rail 4 so that the supporting rail plate 3-1 supports the running rail 4.

[0042] 5) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com