Workshop workbench

A workbench and workshop technology, applied in workbenches, manufacturing tools, etc., can solve problems such as uneven workbenches, no solutions, and inability to meet equipment construction requirements, and achieve the effect of improving overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

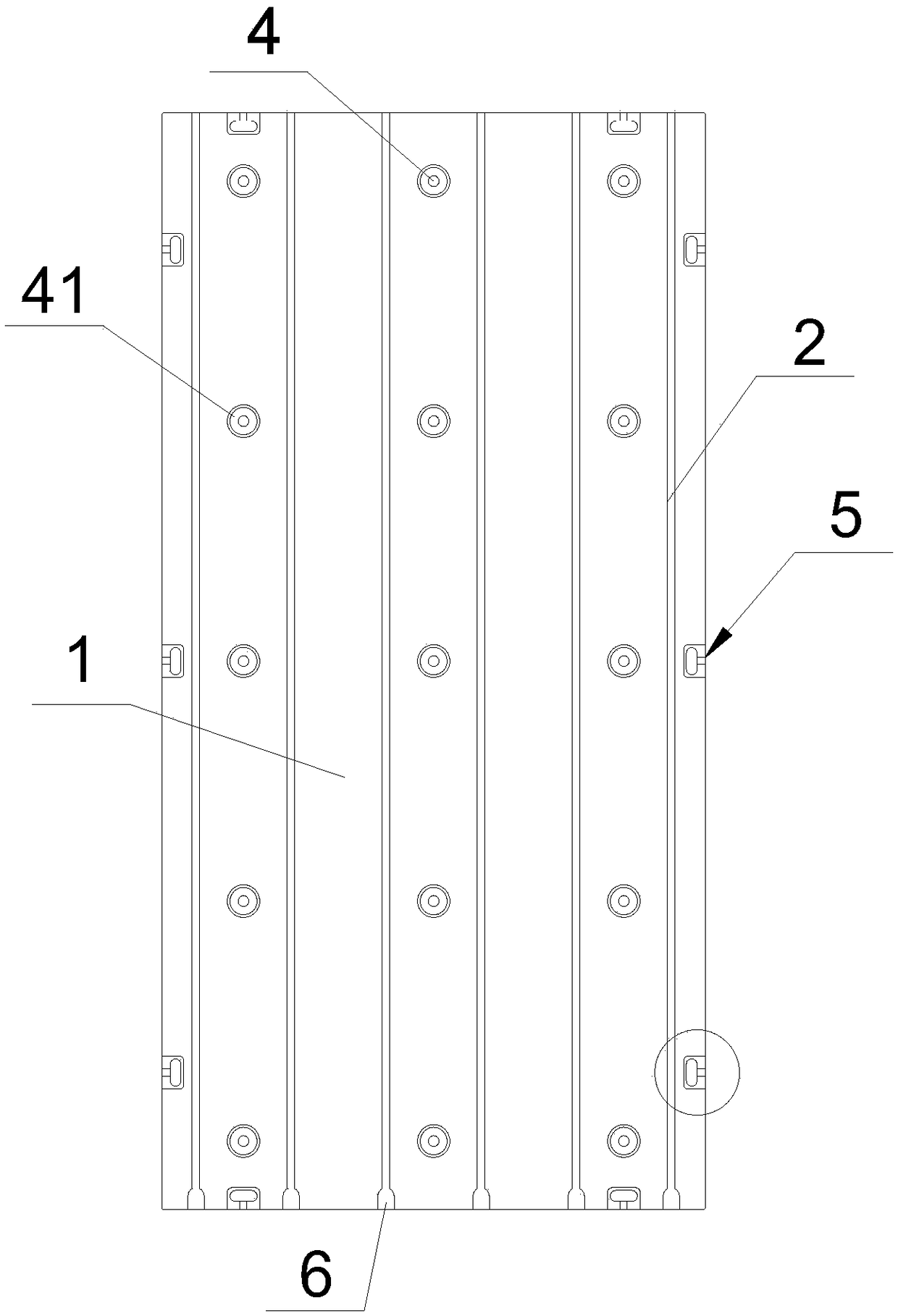

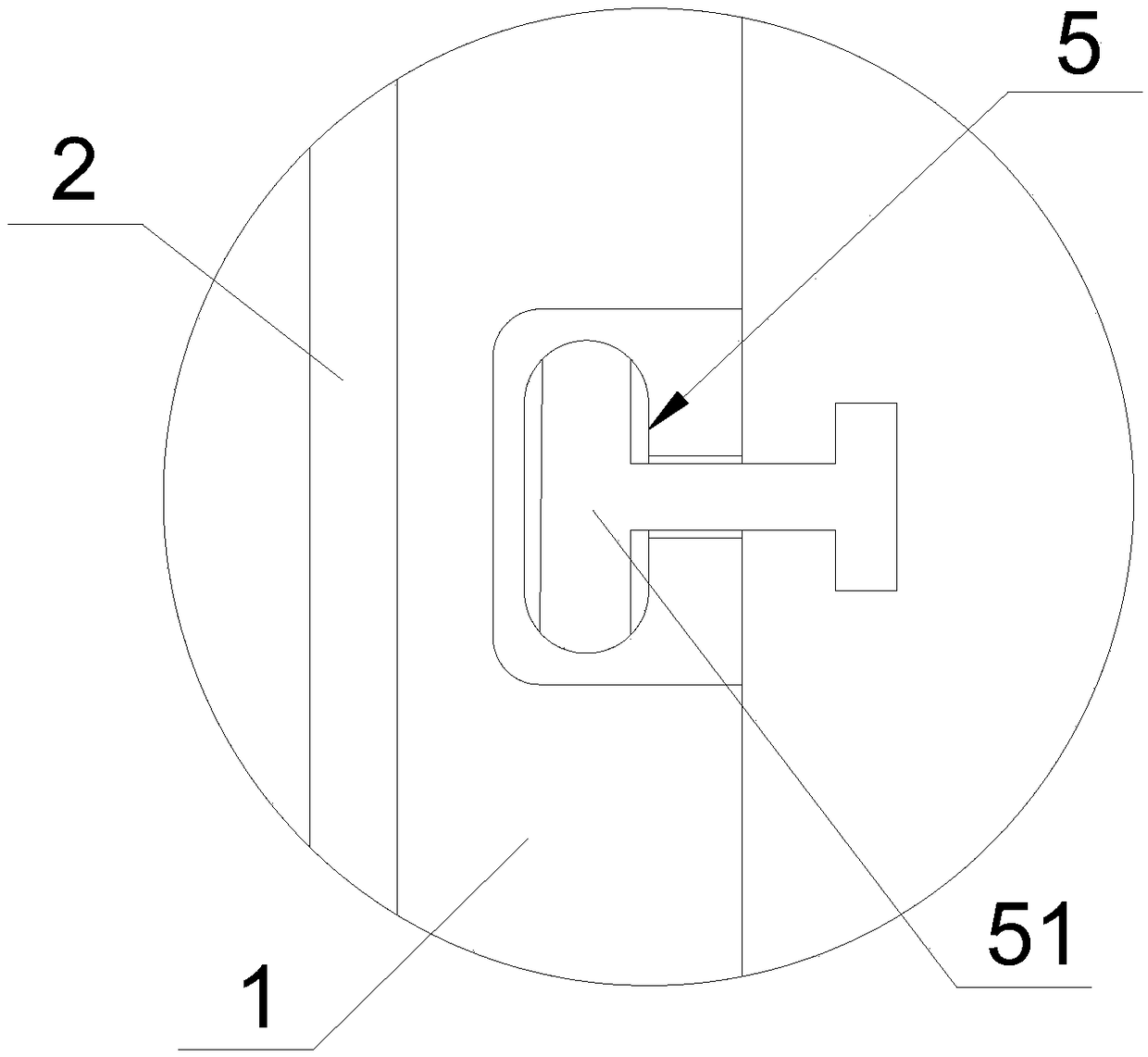

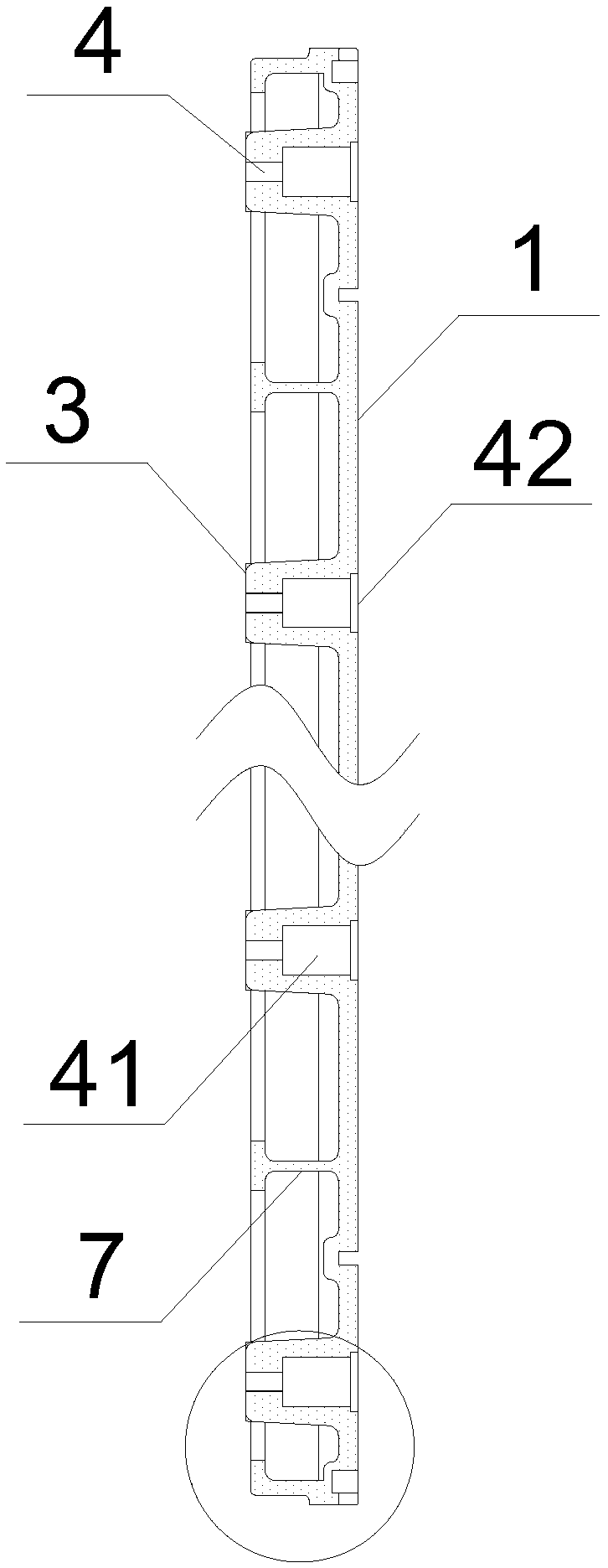

[0031] see figure 1 , image 3 and Figure 5 As shown, the embodiment of the present invention provides a workbench for a workshop, including a table plate 1 and a plurality of fixing grooves 5 arranged on the edge of the table plate 1, and a plurality of chute 2 is provided on one side of the table plate 1, and the cross section of the chute 2 is T-shaped. , preferably, several chutes 2 are arranged parallel to each other at intervals, and the platform 1 extends to the other side to form a number of protrusions 3, and the protrusions 3 on the platform 1 are also provided with mounting holes 4 and fixing grooves 5 through the platform 1 Set on the same plane as the chute 2, and set on the edge of the platen 1, the fixed grooves 5 arranged on the opposite side of the platen 1 are arranged symmetrically in pairs, the set chute 2, and the sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com