Male rivets dismantling bushings

A bushing and rivet technology, applied in the direction of the drilling mold used for workpieces, etc., can solve the problems of drilling damage of parts, vertical parts of the drill bit, fixing the drill bit, damage of parts, etc., and achieve the effect of convenient disassembly, improvement of disassembly efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

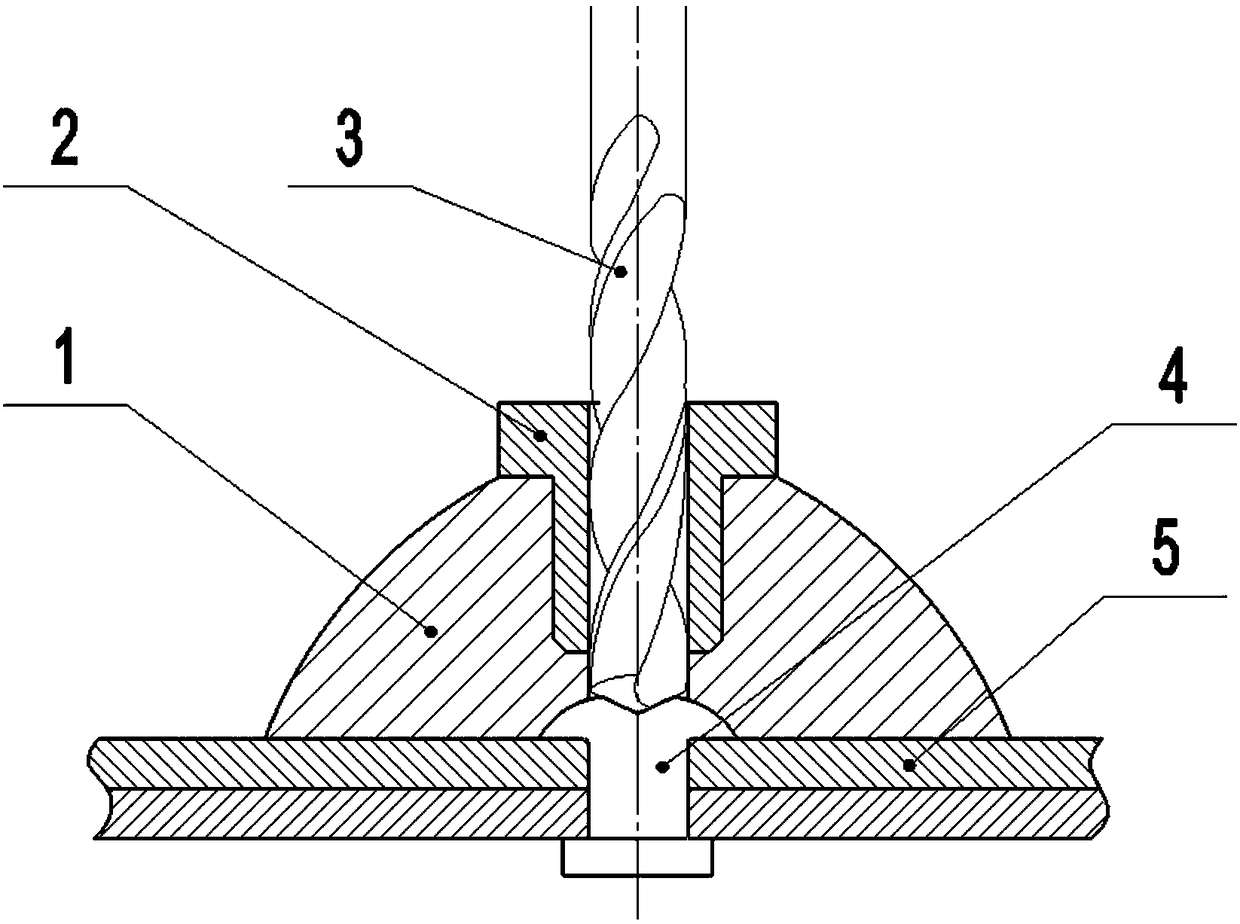

[0014] see figure 1 , The male rivet decomposition bushing of the present invention consists of two parts, one is a fixed bushing adapted to the shape of the rivet head, and the other is a drilling bushing for guiding the drill to drill vertically along the center of the rivet hole. The center of the fixing bush is a through-step hole, and the bottom of the step hole is an arc-shaped structure matching the shape of the rivet head, so as to be better fixed in the center of the rivet head and avoid slippage. In addition, the fixed bushing is made of transparent engineering materials, such as plexiglass, etc., and the main body of the fixed bushing is a curved lens structure, and the bottom of the central through hole is the optical focus of the curved lens structure, so when drilling, the fixed bushing The sleeve can realize the optical magnification of the riv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com