Laser welding method based on automatic alignment device and device

A laser welding and automatic alignment technology, applied in laser welding equipment, auxiliary devices, welding equipment, etc., can solve the problems of affecting the welding strength of the steel bottom and the cup body, polluting the cup body, and the offset of the steel bottom, so as to improve the finished product. The effect of quality, ease of positioning, and reduced difficulty of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

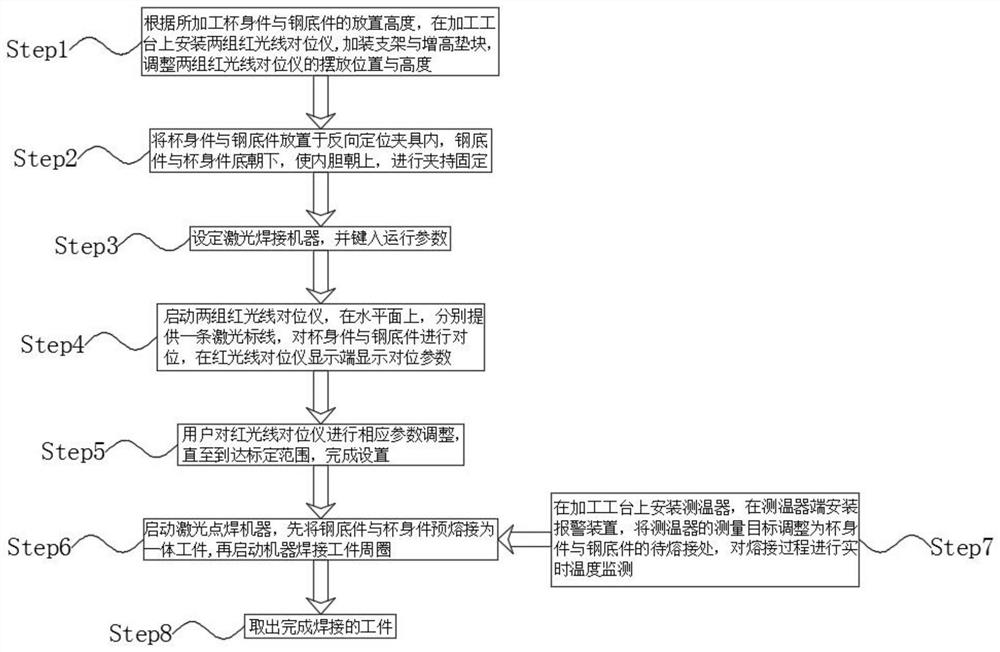

[0052] The laser welding method based on the automatic alignment device of the present embodiment, such as figure 1 shown, including the following steps:

[0053] Step1: According to the height of the processed cup body and steel bottom, install two sets of red light alignment instruments on the processing table, install brackets and heightening pads, and adjust the placement positions of the two sets of red light alignment instruments and height;

[0054] Step2: Place the cup body and steel bottom part in the reverse positioning fixture, the steel bottom part and the cup body face down, make the inner liner face up, and clamp and fix, the steel bottom part and the cup body surface Logo keep consistent;

[0055] Step3: Set up the laser welding machine and enter the operating parameters;

[0056] Step4: Start two sets of red light alignment instruments, provide a laser marking line on the horizontal plane, align the cup body and steel bottom, and display the alignment parame...

Embodiment 2

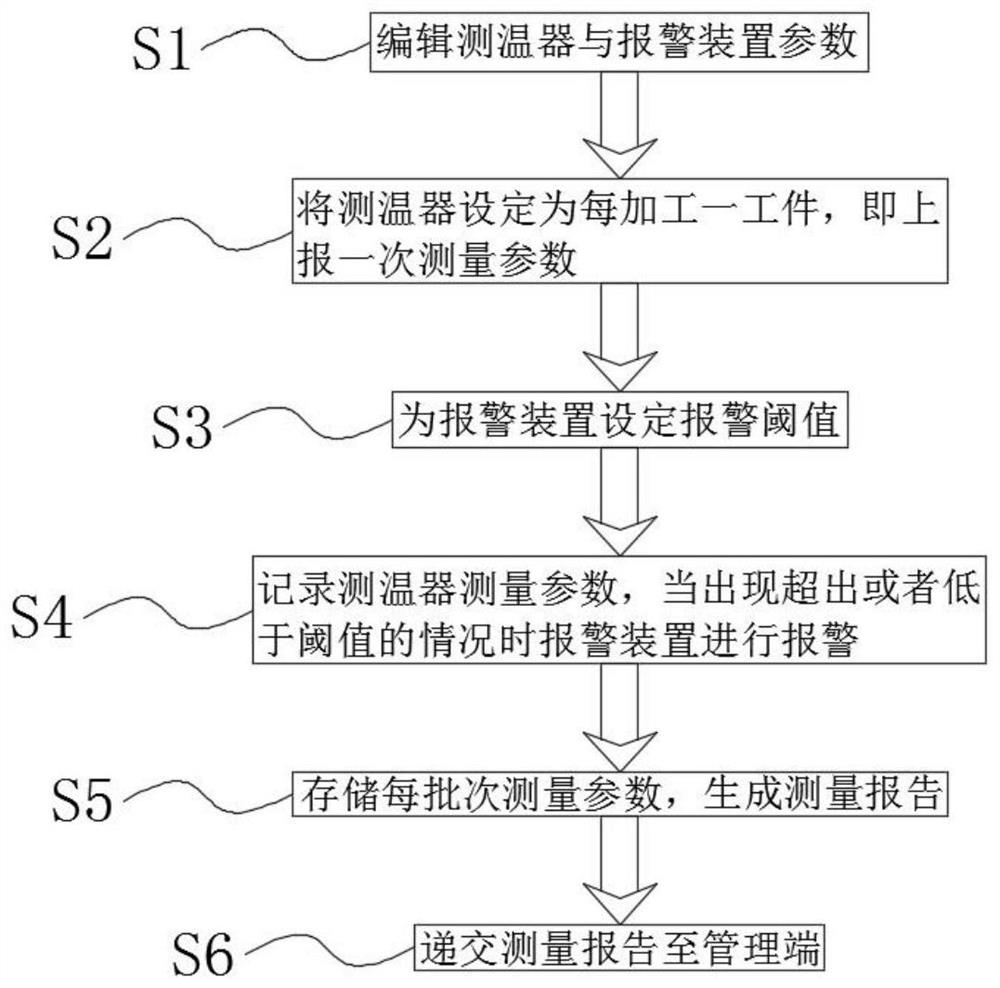

[0074] At other levels, such as figure 2 As shown, the setting method of real-time temperature monitoring in the step Step7 includes the following steps:

[0075] S1: Edit the parameters of the temperature detector and alarm device;

[0076] S2: Set the temperature detector to report the measurement parameters once every time a workpiece is processed, and measure the temperature during welding;

[0077] S3: setting an alarm threshold for the alarm device;

[0078] S4: Record the measurement parameters of the temperature detector, and the alarm device will alarm when the situation exceeds or falls below the threshold;

[0079] S5: Store each batch of measurement parameters and generate a measurement report;

[0080] S6: Submit the measurement report to the management terminal.

[0081] Such as figure 2 As shown, the temperature detector and the alarm device are interactively connected through a wireless network, and the temperature detector shares data to the data receiv...

Embodiment 3

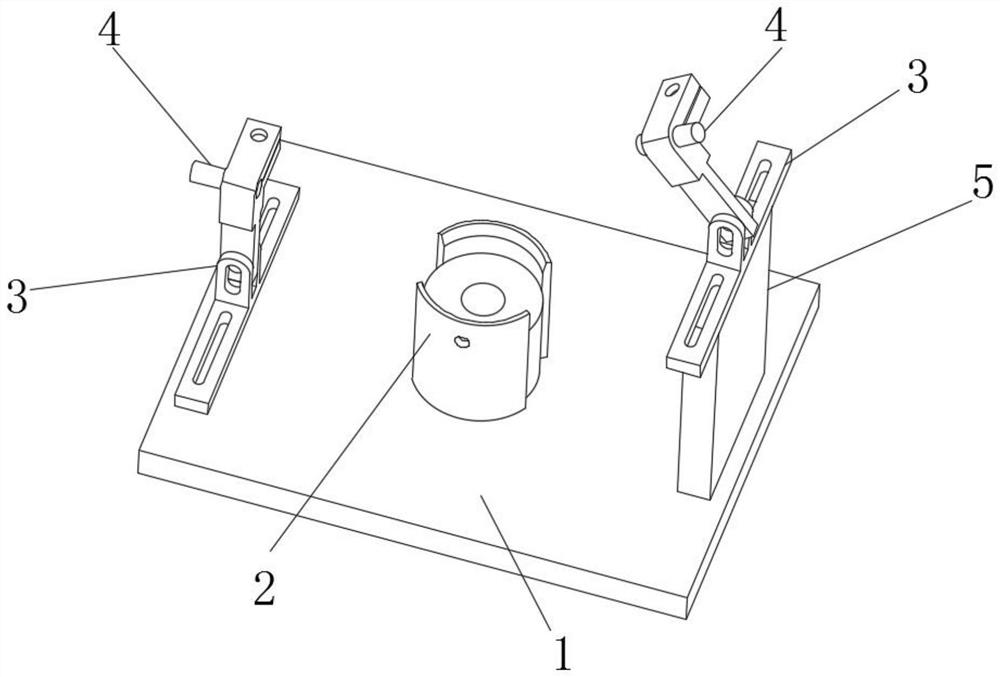

[0085] In this embodiment, an automatic alignment device, such as image 3 As shown, including a workbench 1, a reverse fixture 2 is installed in the middle of the top of the workbench 1, and two groups of infrared alignment instruments 4 are arranged on the top of the workbench 1, and the bottom of the infrared alignment instrument 4 A mounting frame 3 is installed at the end, and the mounting frame 3 is installed on the surface of the workbench 1, and the bottom end of the infrared alignment instrument 4 on the right side is provided with a cushion block 5.

[0086] In the actual implementation of this example, before welding the steel bottom part and the cup body, the user puts the cup body and the steel bottom part into the reverse clamp 2, adjusts the logo on the surface of the steel bottom part and the cup body to be consistent, and then Clamp it so that both the steel bottom part and the cup body face down, and the liner faces up without touching any objects, which effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com