Simplified punching die

A mold and punching technology, applied in the field of simplified punching molds, can solve the problems of no competitive advantage, long mold production cycle, high product price, and achieve the effects of simple and practical processing and development, easy portability and transportation, and low processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

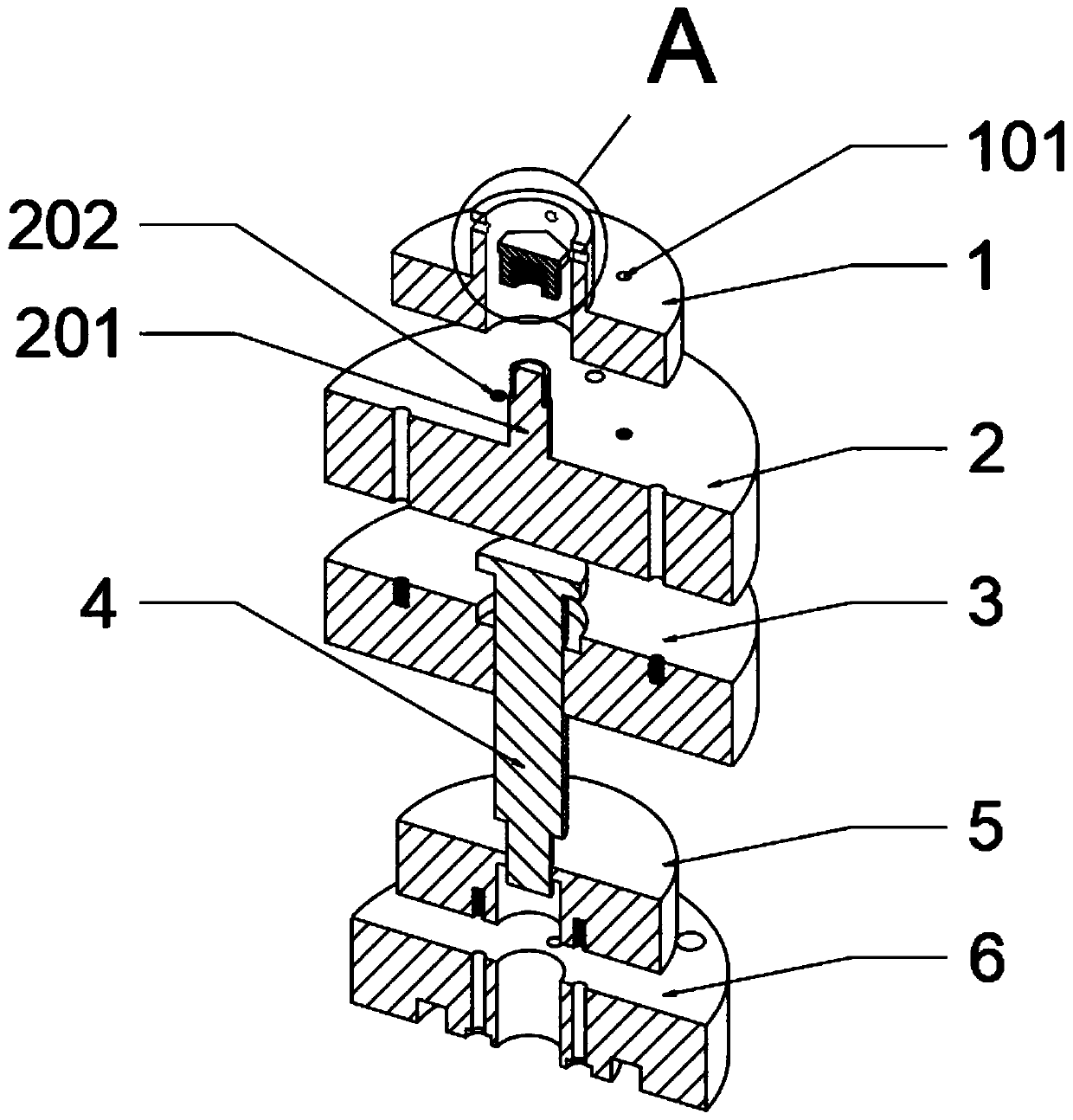

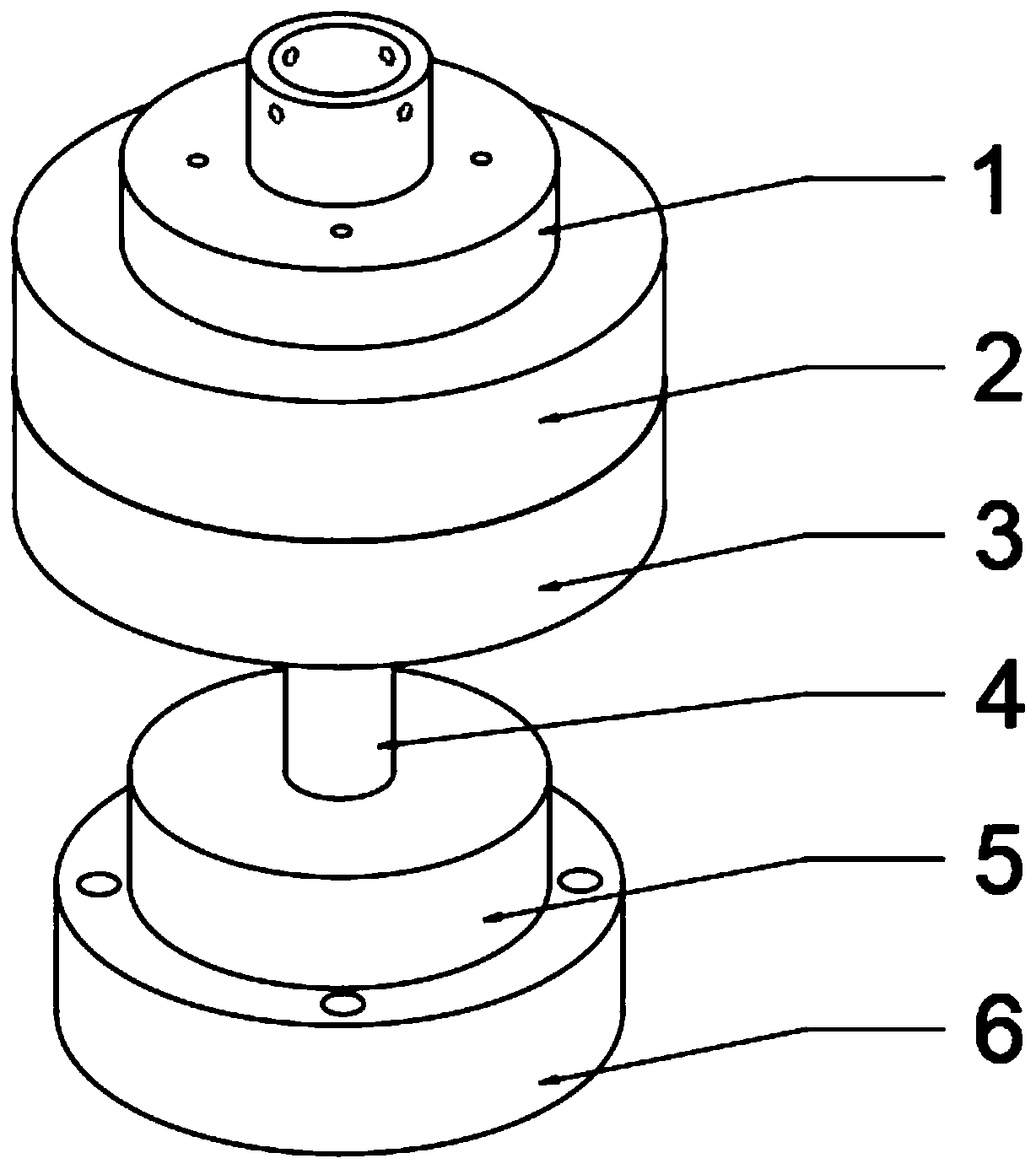

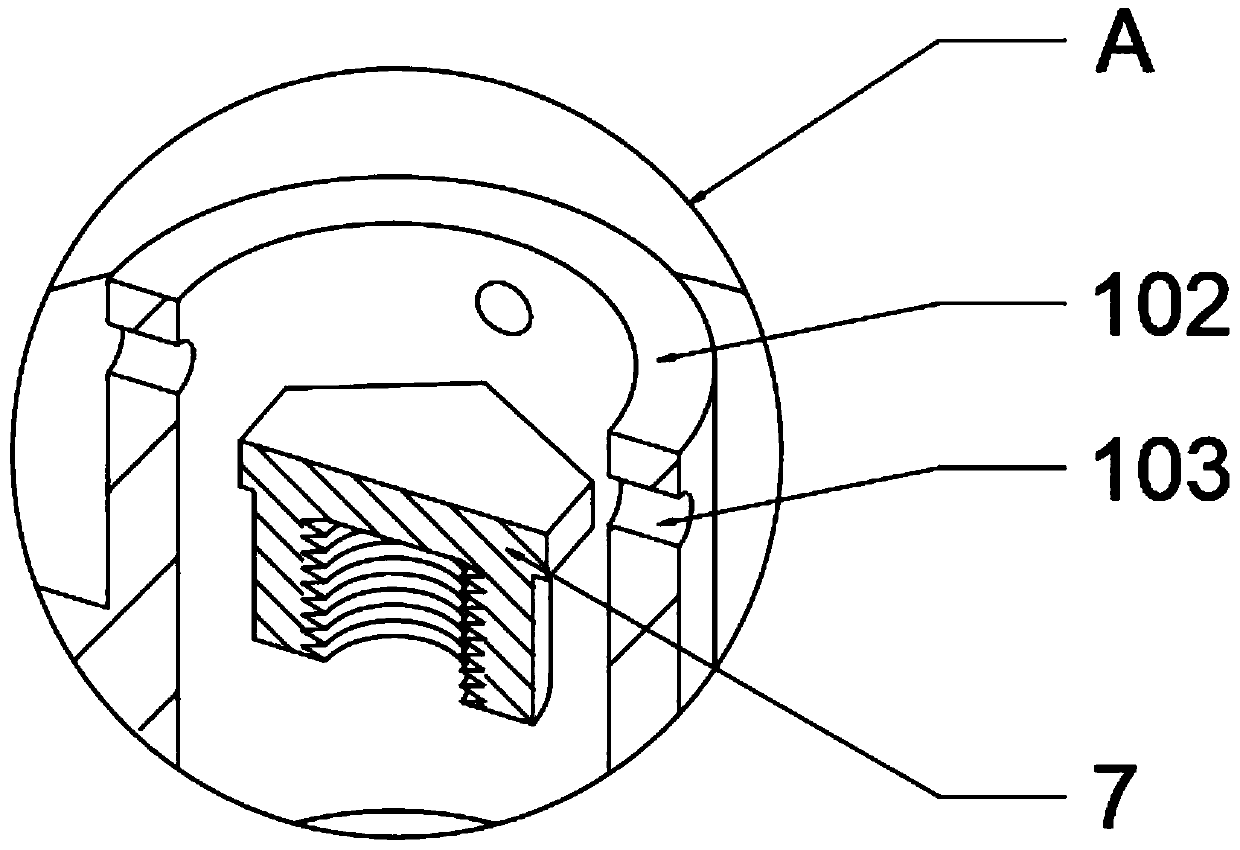

[0024] as attached figure 1 to attach image 3 Shown:

[0025] The present invention provides a simplified punching die, which includes a die handle 1, a die handle through hole 101, a die handle barrel 102, a circumferential position control hole 103, an upper template 2, a connecting rod 201, an auxiliary screw hole 202, and a punch fixing plate 3. Punch 4, die 5, bottom plate 6 and screw cap 7; four groups of die handles 1 are provided with four groups of die handle through holes 101; four groups of auxiliary screw holes 202 are provided around the top of the upper template 2, And the upper template 2 passes through the mold handle through hole 101 through the screw and inserts the auxiliary screw hole 202 to be positioned and connected with the mold handle 1; four groups of through holes are provided around the middle of the upper template 2; four groups of the punch fixing plate 3 are provided with Four sets of screw holes, and a T-shaped hole is opened in the middle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com