Automobile flywheel casting process and device thereof

A casting process and flywheel technology, applied in the field of sand casting, can solve the problems of low production efficiency and complex working process, and achieve the effects of high production efficiency, simple process and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

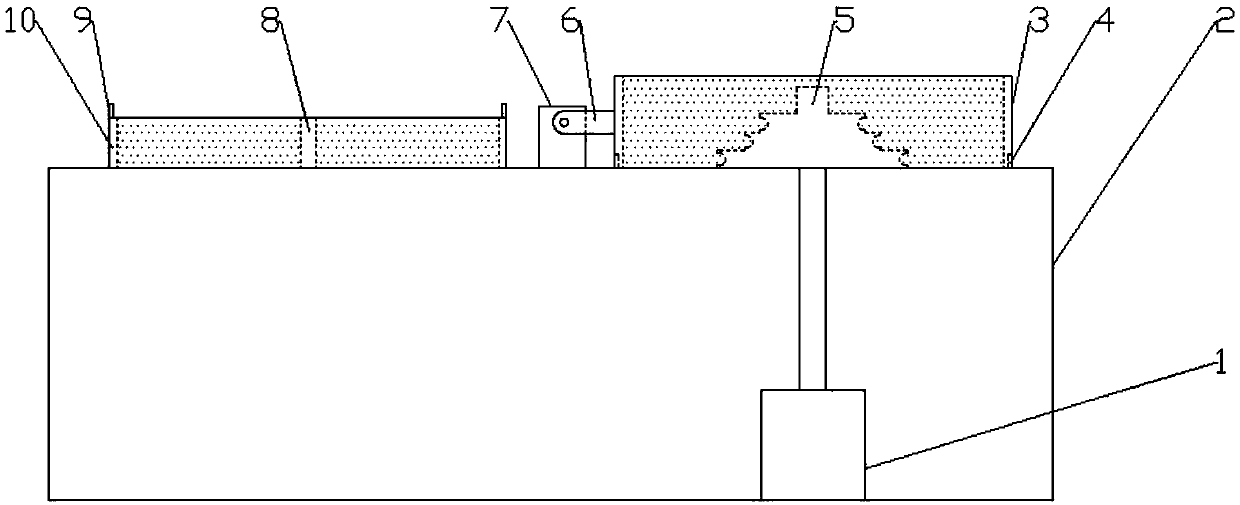

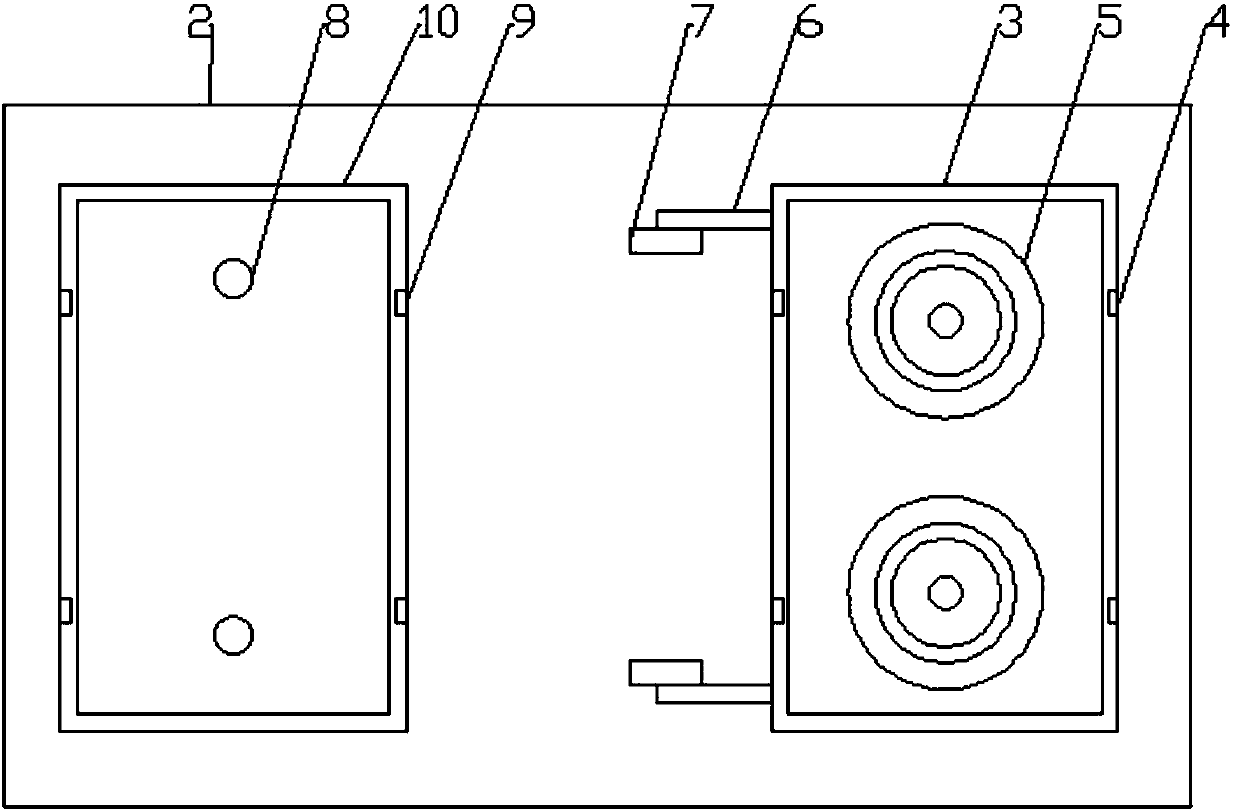

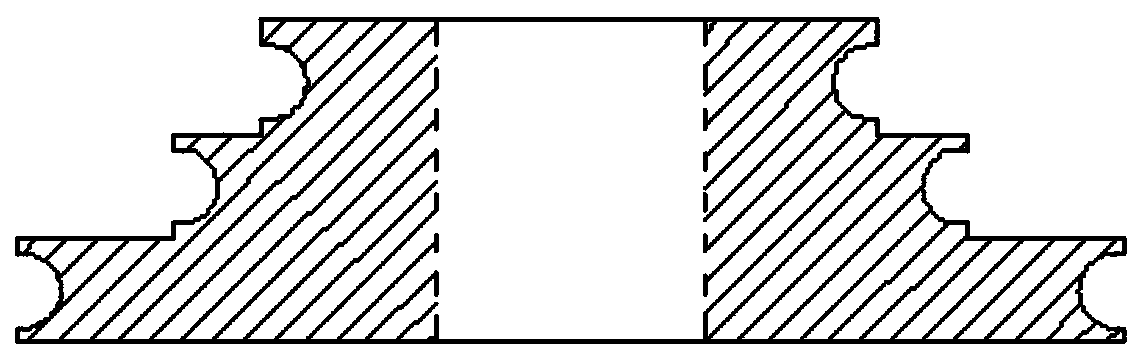

[0025] Figure 1-3 Show the specific embodiment of the present invention: a kind of automobile flywheel casting process, comprises the following steps:

[0026] Step 1, raise the model 5, and turn the sand box 3 to the upper end of the model 5;

[0027] Step 2, sprinkle anti-adhesive material, sprinkle a layer of anti-adhesive material on the surface of model 5;

[0028] Step 3, filling molding sand, adding molding sand to the upper end of the model 5, and compacting the molding sand so that the surface of the molding sand is neat and does not exceed the height of the flask 3;

[0029] Step 4, turn over the sand box 3, slowly lower the model 5, and then slowly turn the sand box 3 to the other end of the workbench 2;

[0030] Step 5, sprinkle the molding sand, sprinkle the molding sand on the surface of the overturned sand box 3, and then blow off the excess molding sand with a fan;

[0031] Step 6, hardening, evenly spraying the hardening agent to the inside of the sand box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com