Construction method of a cantilever steel frame plastic formwork

A plastic formwork and construction method technology, which is applied in sea area engineering, water conservancy engineering, infrastructure engineering, etc., can solve the problems of large construction consumption, expensive technology and complexity of components, and achieve the goals of saving use, improving installation efficiency, and improving construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

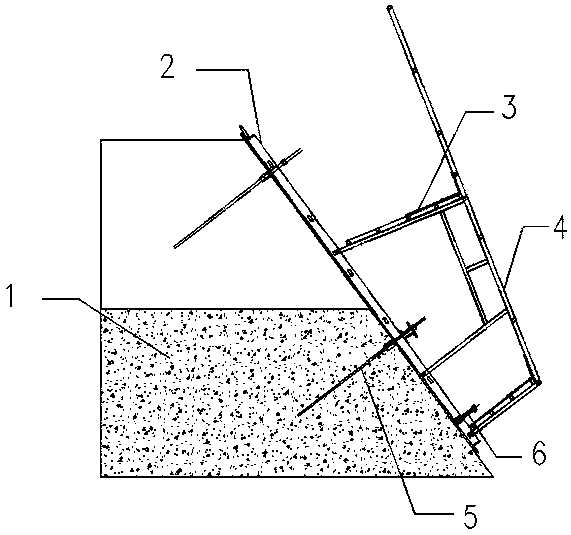

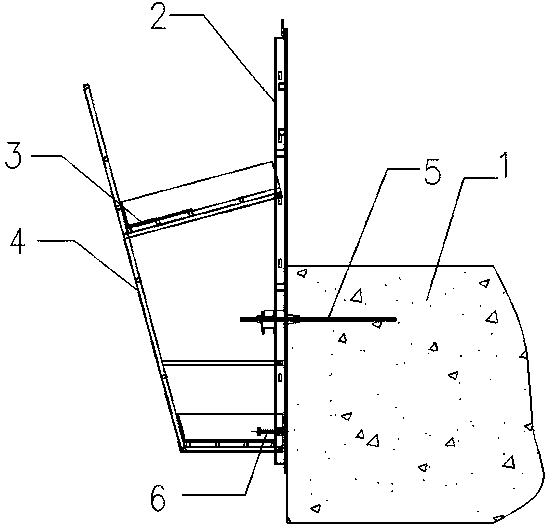

[0034] Such as figure 1 , figure 2 A construction method of a cantilevered steel frame plastic formwork shown specifically includes the following steps:

[0035] S1: tower crane for formwork

[0036] S1.1: Lift the formwork tower to the installation area of the formwork by means of a tower crane. The tower adopts several slings, and the slings pass through a number of through holes matched with the slings set on an iron plate and then connect to the formwork , realize the formwork tower crane.

[0037] S2: Assembly of template:

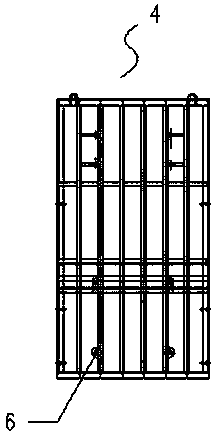

[0038] S2.1: After the formwork is tower craned to the installation area, assemble the formwork in the installation area according to the drawings. They are hingedly connected to the protective outer frame 4 and the stressed channel steel 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com