A built-in installed and fixed toilet and its installation and fixing method

A toilet and built-in technology, applied in water supply devices, buildings, flushing toilets, etc., can solve problems such as troublesome tightening process, laborious tightening of nuts, difficulty in tightening nuts by hand, etc., and achieve the effect of labor-saving installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

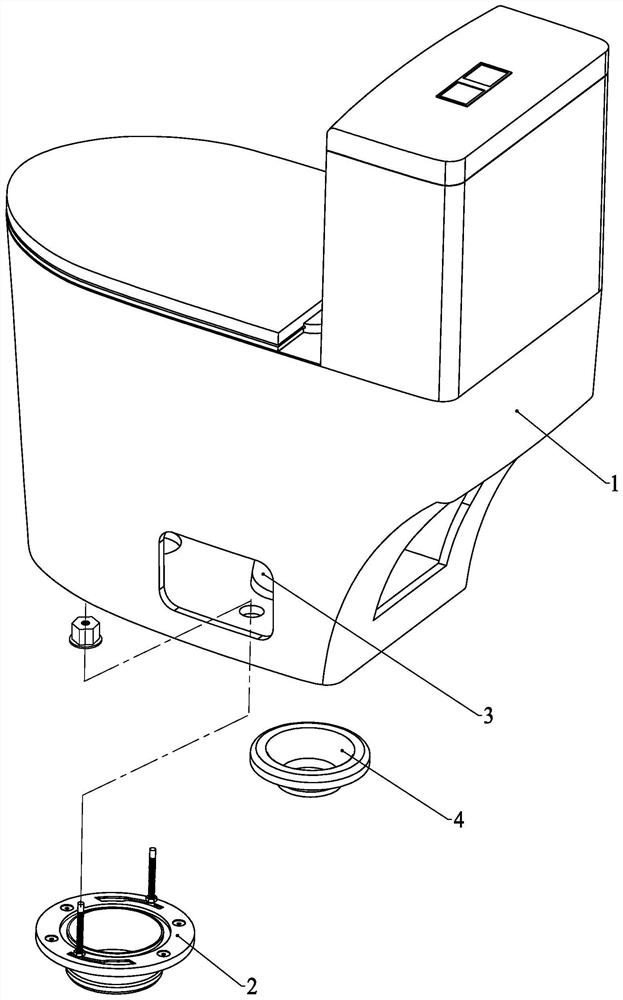

[0030] refer to figure 1 , the existing known ceramic toilet, respectively offer a width * height is about 150mm * 100mm square gap or diameter is about 150mm circular gap in the two side wall panels of the toilet, so that from the two sides of the toilet On the side, let your hand reach the bottom of the toilet to tighten the nut, so that the toilet assembly is fixed.

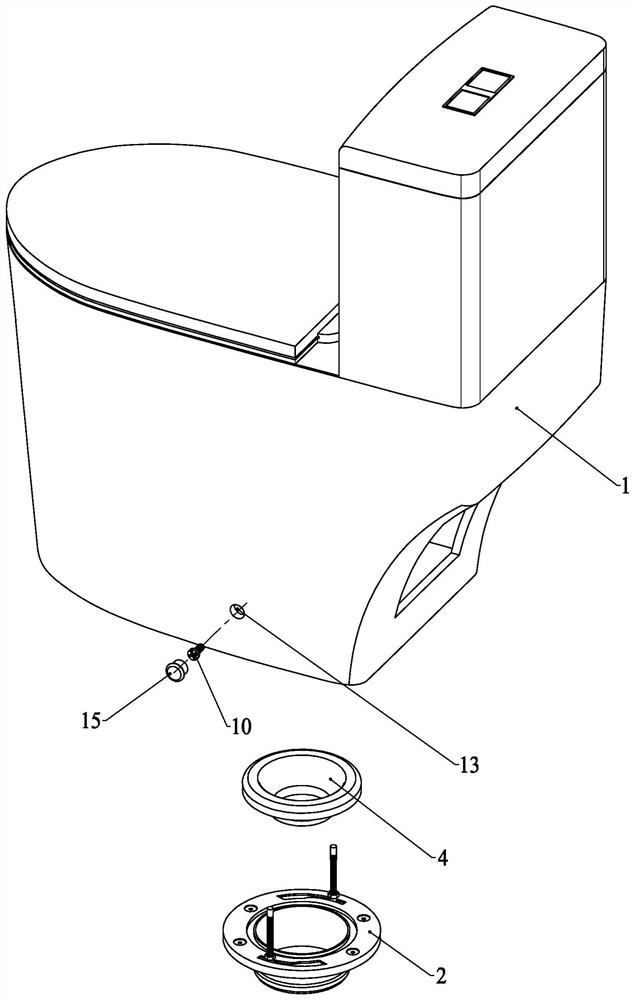

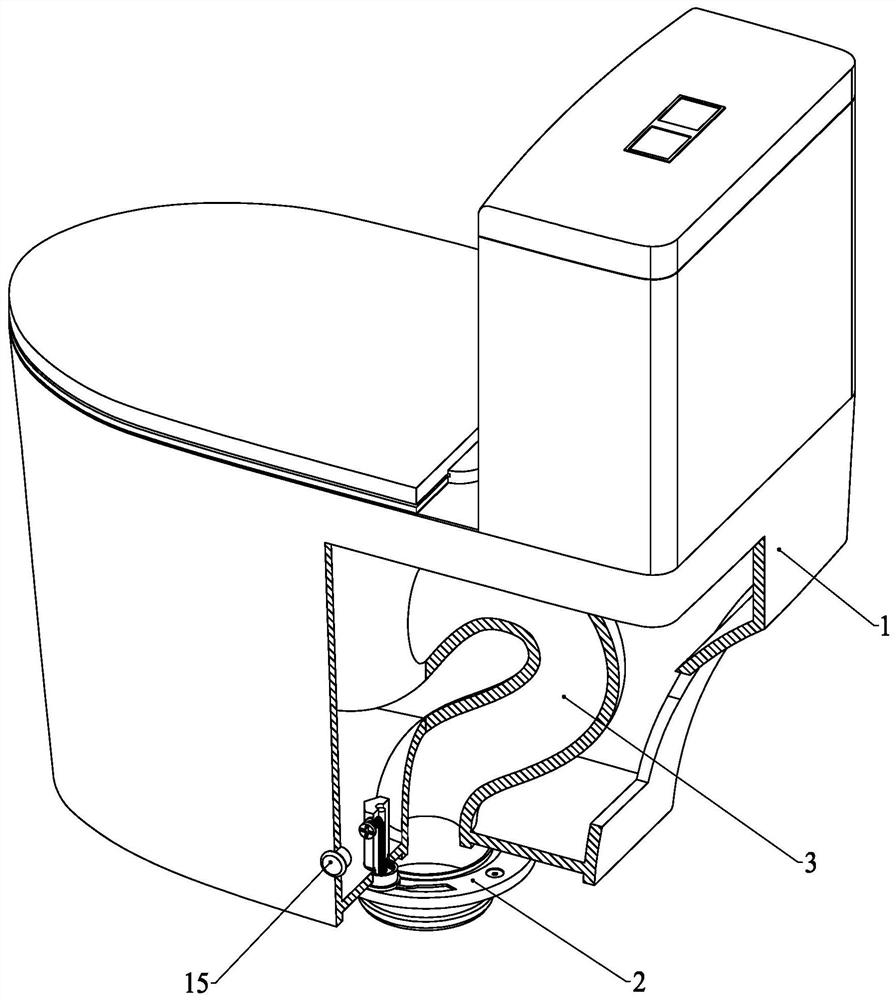

[0031] refer to Figure 2 to Figure 8 , this embodiment is a built-in fixed toilet, including a toilet body 1 and an installation and fixing device fixedly connected to the toilet sewage pipe connection flange 2, the sewage pipe 3 of the toilet body is sealed by the sealing flange 4 On the connecting flange of the sewage pipe; the bottom plate 5 of the toilet body is symmetrically provided with mounting holes 6 on both sides of the sewage pipe, and a mounting and fixing device is arranged at the position of the mounting hole on each side; the mounting and fixing device includes a vertical rod 7 and a rod slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com