Quick-heating abrasive floor tile

A technology of rapid heating and floor tiles, which is applied in the field of furniture, can solve the problems of inapplicability, and achieve the effect of increasing temperature, not easy to bulge, and strong impervious pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

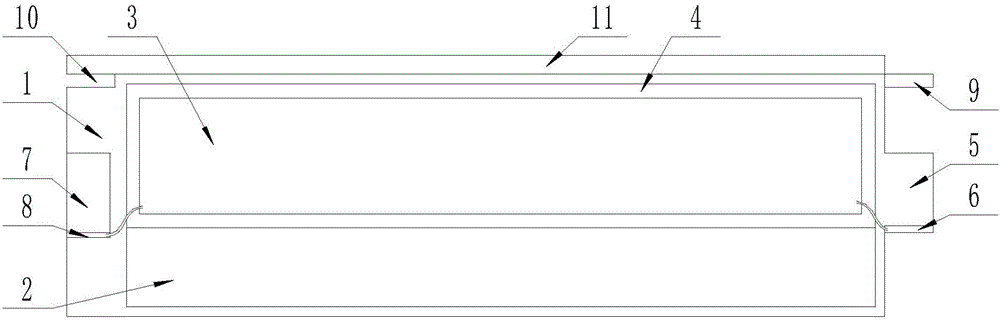

[0013] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, a fast heating non-slip floor tile includes a floor tile body 1, the interior of the floor tile body 1 is a hollow structure, and the heat insulation layer 2 arranged at the bottom in the hollow structure of the floor tile body 1 is located on the heat insulation layer 2. The heating plate 3, the waterproof layer 4 coated on the outer surface of the heating plate 3, the convex rib 5 arranged on the outer surface of the floor tile body 1, the No. The electrode 6 is arranged on the surface of the other side of the floor tile body 1 and corresponds to the groove 7 at the position of the convex edge 5. At the bottom of the groove 7, there is a electrode that matches the No. 1 electrode 6 and is connected to the heating plate 3 through a wire. On the second electrode 8, a rectangular waterproof eaves 9 is provided on the outer side of the floor tile body 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com